Component for Machine Structure, Method of Producing the Same and Material for Induction Hardening

a machine structure and component technology, applied in the direction of increasing energy efficiency and improving process efficiency, can solve the problems of insufficient satisfaction of the demand for fatigue strength, poor productivity, saturated fatigue strength at a certain depth, etc., and achieve excellent fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

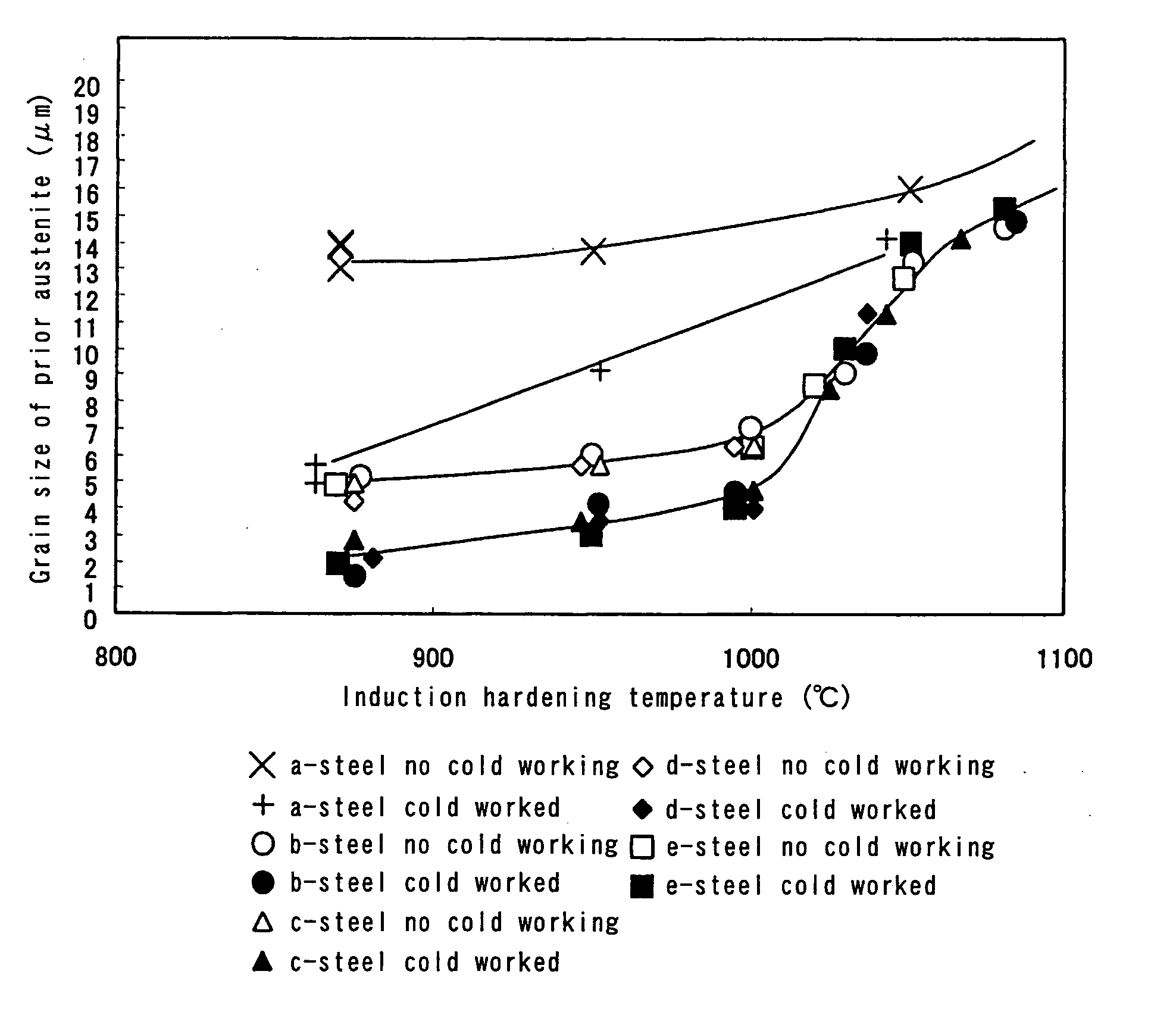

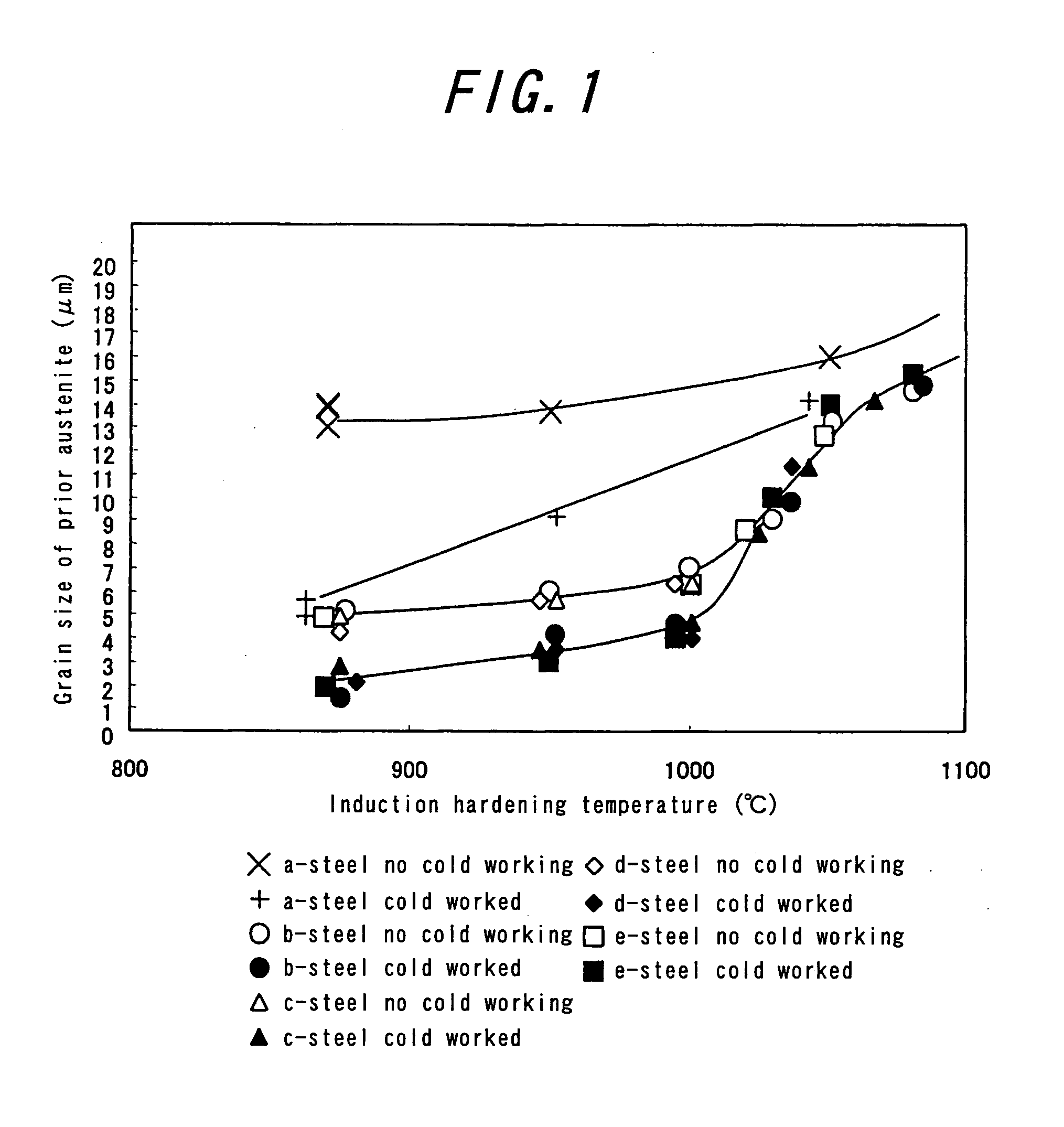

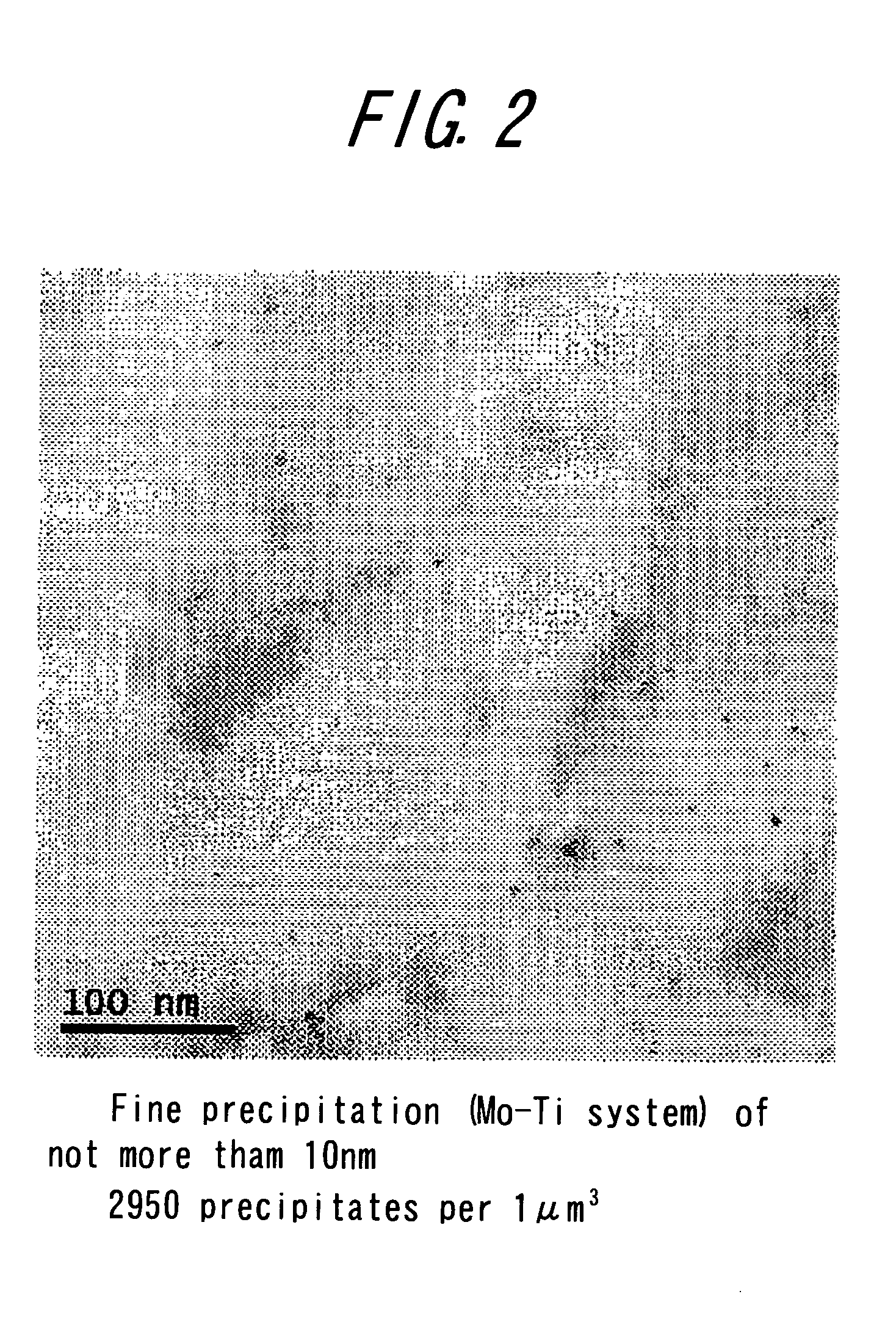

[0166]100 kg of a steel shown in Table 1 is melted and heated to 1200° C. and shaped into a sample for torsional fatigue test under hot working conditions and cold working conditions shown in Table 2. The shaped sample is first subjected to an induction hardening at 1050° C. and subsequently to an induction hardening under conditions shown in Table 2. Moreover, the induction hardening at 1050° C. is not carried out in Test No. 10. Also, in the tests other than Test Nos. 29 and 30, the tempering of 160° C.×1 h. is carried out after the induction hardening. The grain size of prior austenite and hardness in the induction hardened portion are measured in the same method as mentioned above. In the torsional fatigue test, stress broken at torsion number of 105 is measured on the torsional stepped test specimen of 18 mmφ. Also, the microstructure prior to the induction hardening is observed by means of an optical microscope to identify the microstructure, and at the same time the microstru...

example 2

[0168]As a component for machine structure according to the invention is prepared a constant velocity joint 12 interposed for transmitting a motive energy from a drive shaft 10 to a wheel hub 11 as shown in FIG. 5.

[0169]The constant velocity joint 12 is a combination of an outer wheel 13 sand an inner wheel 14. That is, the inner wheel 14 is swingably fixed to an inside of a mouth portion 13a of the outer wheel 13 through balls 15 fitted into a ball track groove formed in the inner face of the mouth portion 13a, while the drive shaft 10 is connected to the inner wheel 14. A stem portion 13b of the outer wheel 13 is, for example, spline-bonded to the hub 11, whereby the motive energy is transmitted from the drive shaft 10 to the hub 11 of the wheel.

[0170]A starting material of steel having a chemical composition shown in Table 3 is melted in a converter and continuously cast to form a cast bloom. The cast bloom has a size of 300×400 mm. The cast bloom is rolled into a billet of 150 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com