Biomass Bio Oil Upgrade Method

a biomass oil and biofuel technology, applied in biofuels, biofuels, waste based fuels, etc., can solve the problems of increasing tar formation, achieve rapid quenching, increase tar formation, and reduce tar formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description is of the best mode presently contemplated for carrying out the invention. This description is not to be taken in a limiting sense, but is made merely for the purpose of describing one or more preferred embodiments of the invention. The scope of the invention should be determined with reference to the claims.

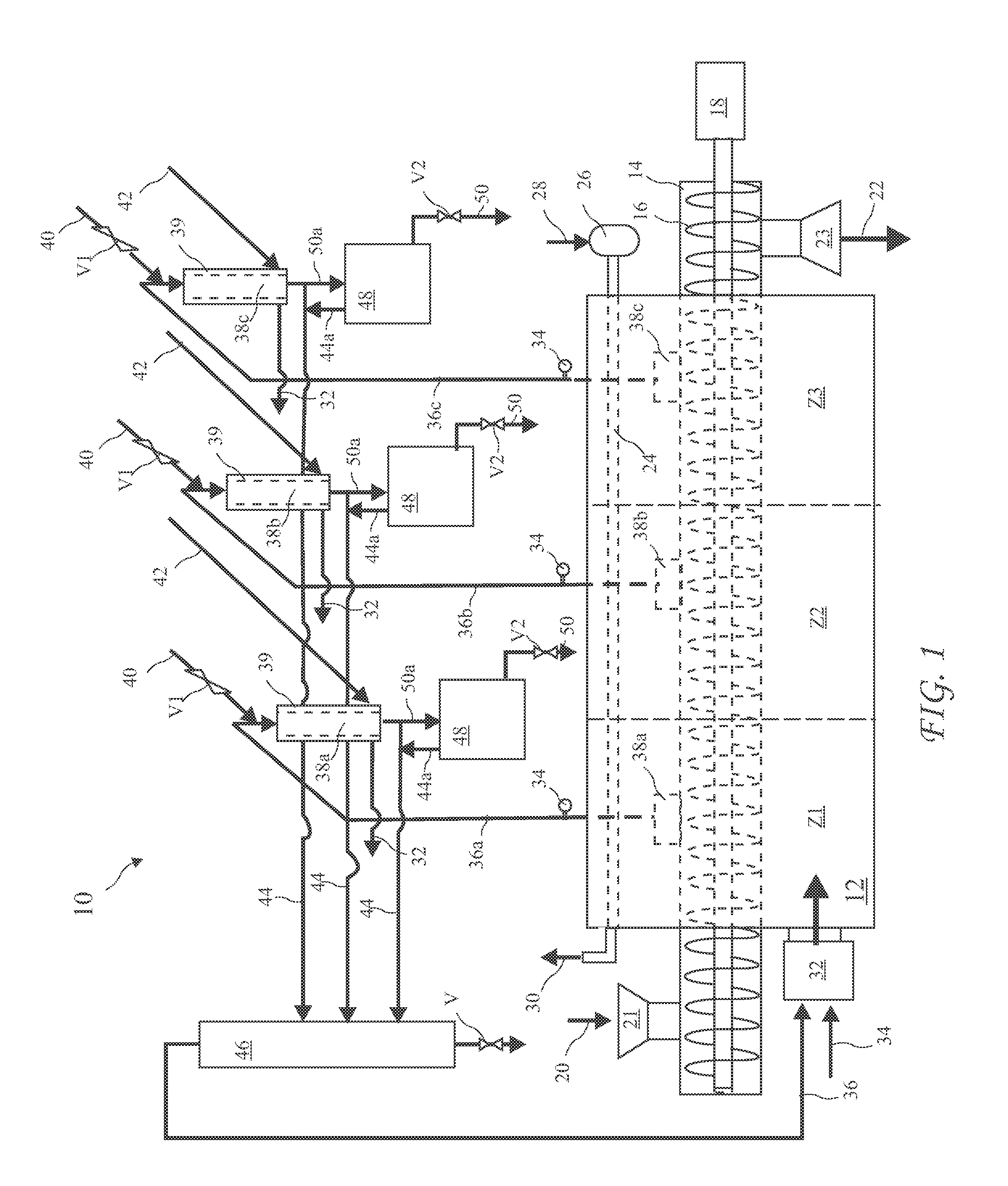

[0032]A pyrolysis system 10 for producing bio oil according to the present invention is shown in FIG. 1. The pyrolysis system 10 primarily includes a pyrolysis chamber 12 and condensers 38a, 38b, and 38c. An auger 16 residing in an auger housing 14 extends through the length of the pyrolysis chamber 12 and is rotated by a motor 18. Biomass feed material 20, for example dry sawdust, is fed through an entry 21 into the auger housing 14 at one end of the pyrolysis chamber 12 and charcoal material 22 is released from the auger housing 14 through a chute 23 at an opposite end of the pyrolysis chamber 12. The interior of the pyrolysis chamber 12 is subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| vapor phase | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com