System for generating brown gas and uses thereof

a technology of brown gas and system, applied in the direction of container/bottle construction, rigid containers, packaging goods, etc., can solve the problems of long-term economic viability and availability, network of exposed pipelines and terminals over a vast area, high risk of external influence, natural disaster or terrorist threat, etc., to achieve rapid quenching of flue gas, high volume, and rapid quenching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

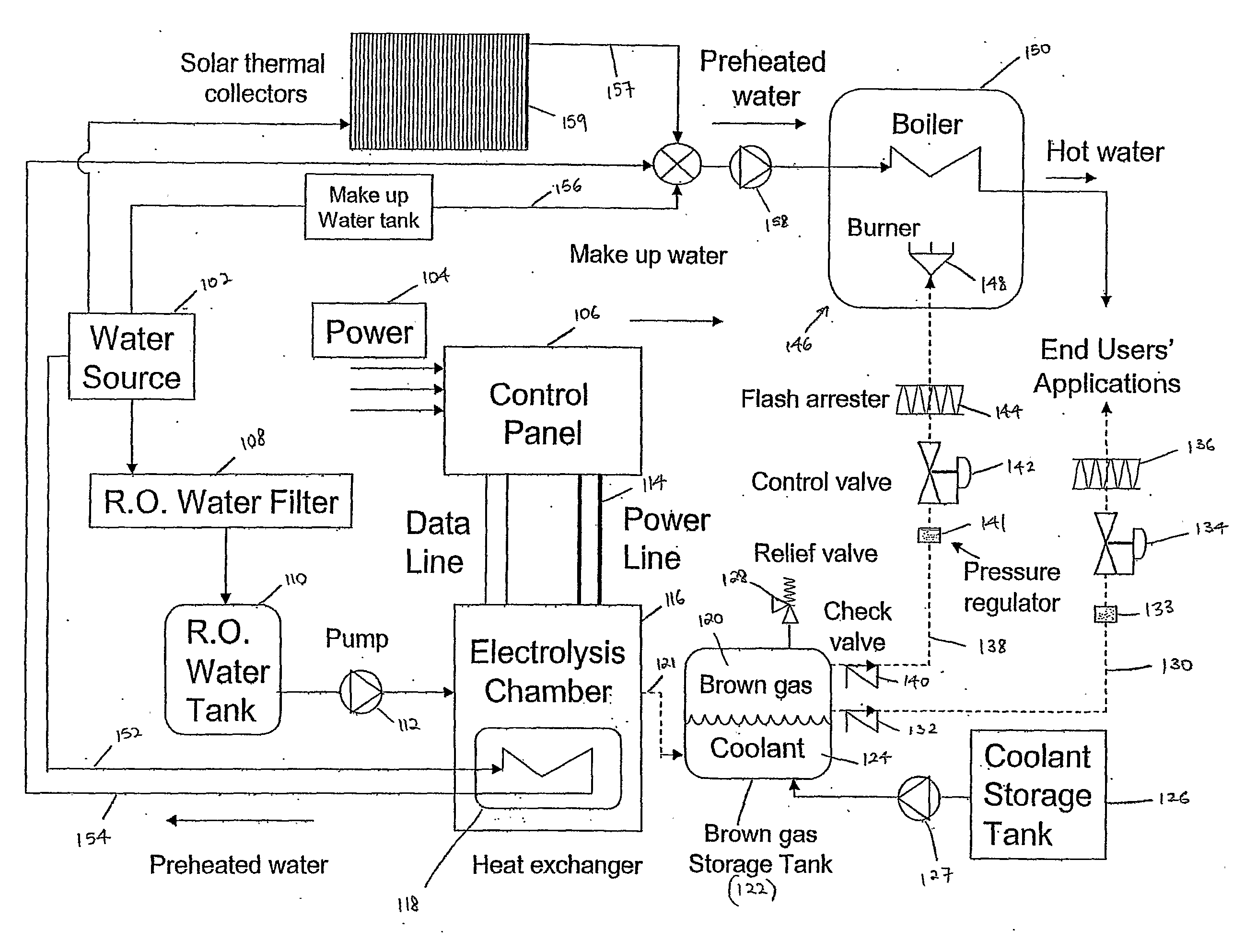

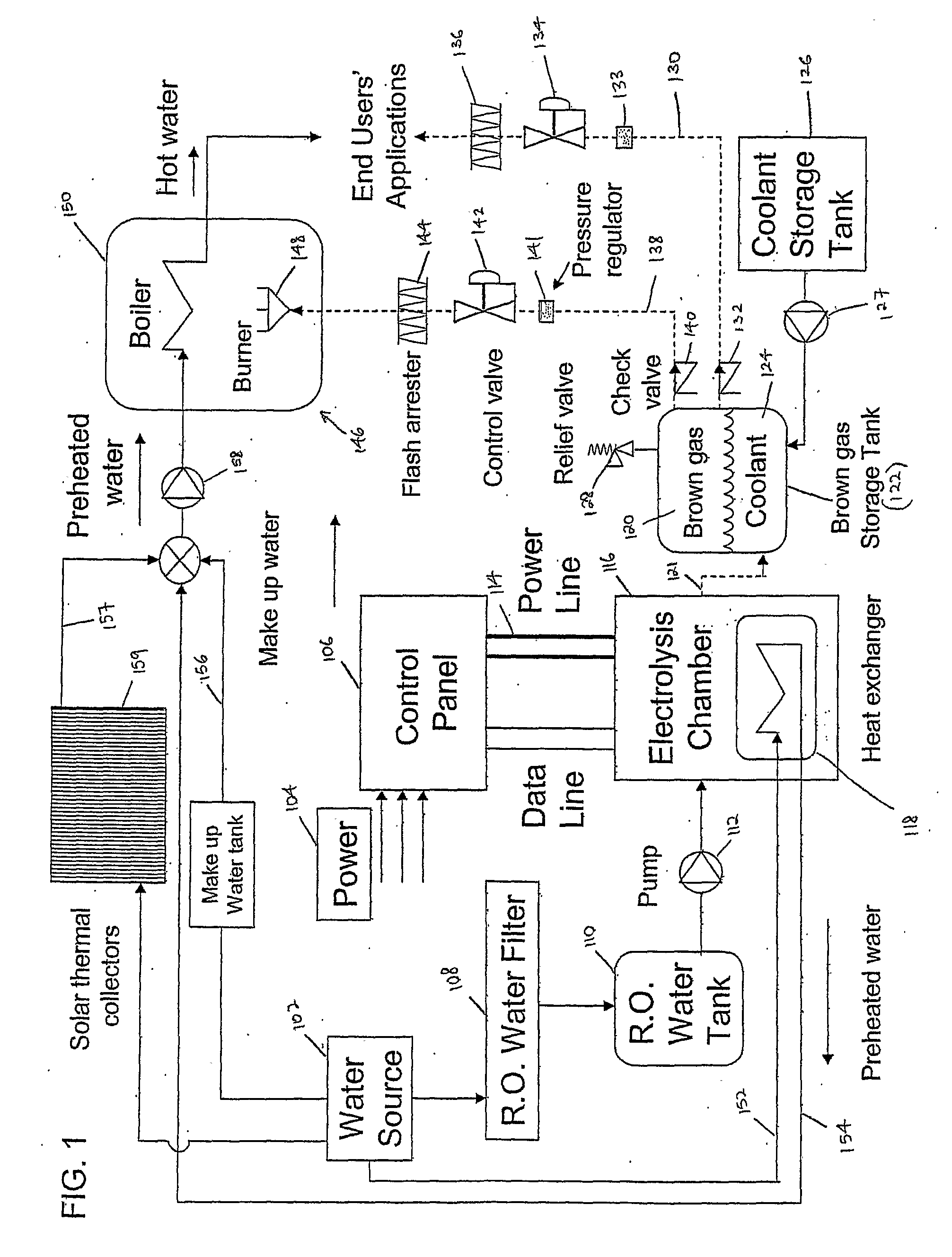

[0167]FIG. 1 shows a part of the isolated system of one embodiment of the present invention. In particular, FIG. 1 shows the generation of Brown's gas and the use of Brown's gas in a boiler and burner unit in an isolated system. Brown's gas is generated in a Brown's gas generator 116, one form being described in U.S. Pat. No. 4,081,656. The generator 116 may include an electrolysis chamber. An electricity supply 104 is connected to a control panel 106 which monitors and controls the operating parameters such as electricity supply to the generator 116 via power lines 114. There is also provided a water supply 102. The water supply 102 may be in the form of a water storage tank. Water from the water supply 102 is passed through a reverse osmosis (RO) water filter 108 and the filtered RO water is stored in a RO water tank 110. Water from the RO water tank 110 is fed into the generator 116 by means of a pump 112.

[0168]Consequently, the generator 116 takes in the RO water and electricity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particulate sizes | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com