Heat treatment device for machine tool spindle production

A heat treatment device and a technology for machine tool spindles, which are applied in the field of machine tools, can solve problems such as uneven quenching, affecting the physical properties of the spindle, and the inability to spray lye, etc., to achieve improved quenching effects, good application prospects, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

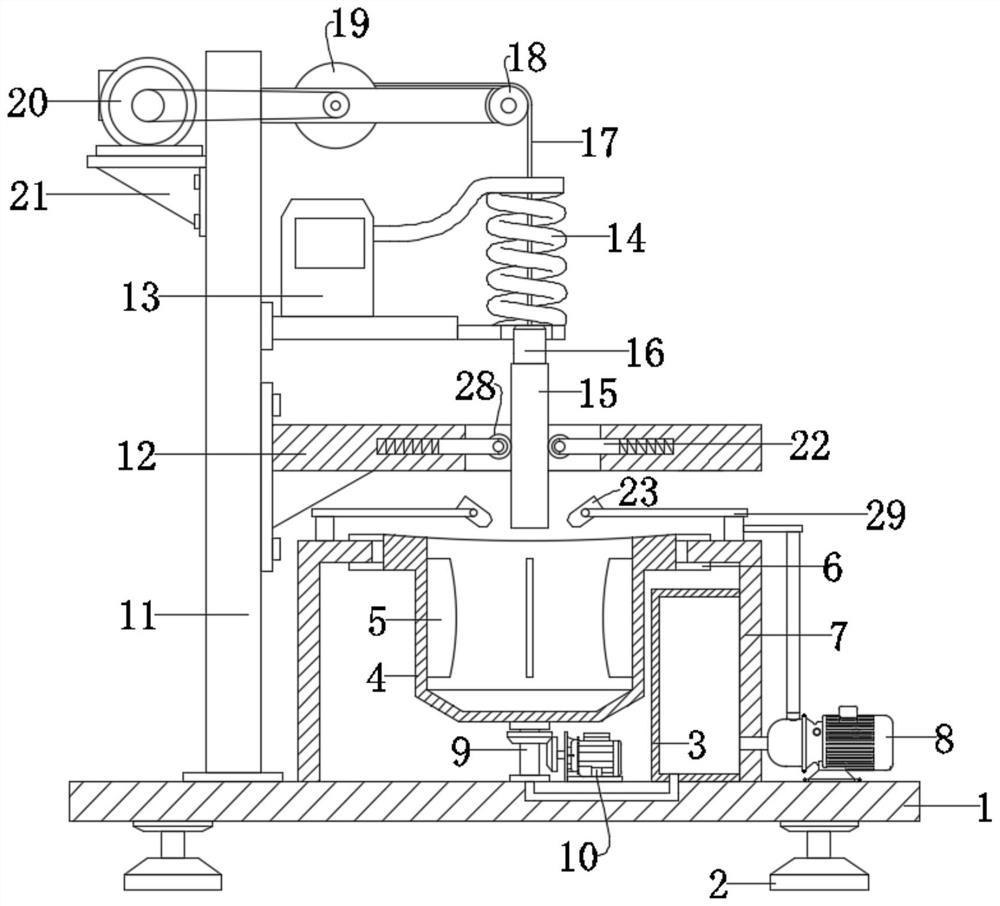

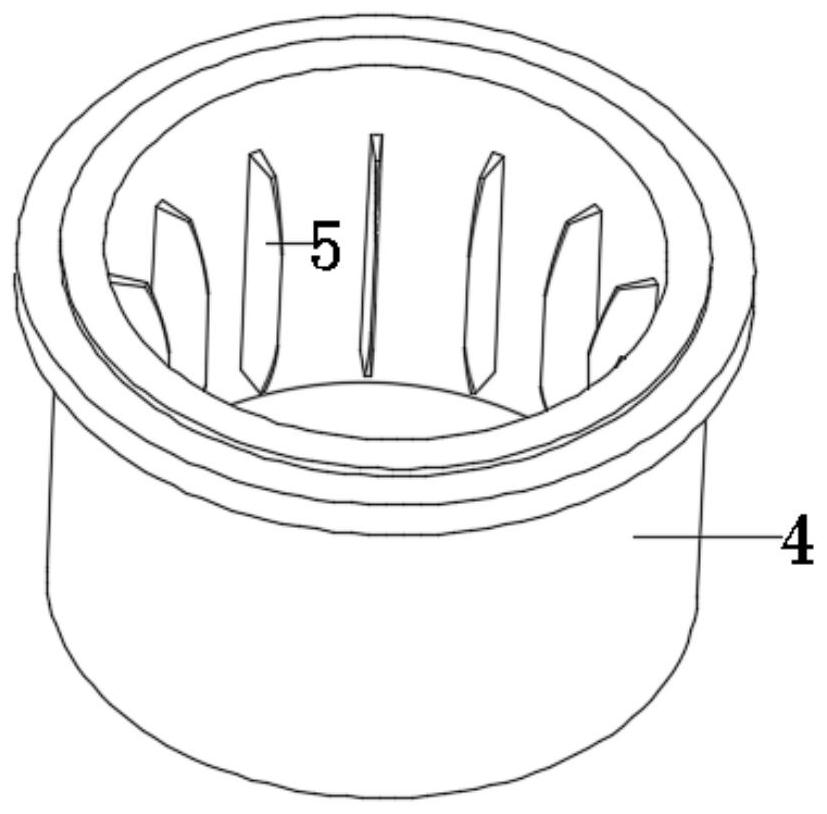

[0020] see Figure 1-2 , a heat treatment device for machine tool spindle production, comprising a base plate 1, a main shaft 15 and a quenching box 4, wherein a support 7 is fixedly connected to the base plate 1, a circular hole is provided at the center of the support 7, and the side of the quenching box 4 The side is fixedly connected with a block 6, and the block 6 is set on the edge of the circular hole, so that the quenching box 4 can rotate along the bracket 7, and a driving device is installed between the bottom plate 1 and the box body, so The driving device acts in the quenching box 4 to further drive the rotation of the quenching box 4; the base plate 1 is fixedly connected with a support 7, and the support 7 is fixedly connected with a carrier plate 12, and the carrier plate 12 is provided with a through hole , the main shaft 15 can pass through the through hole, and a positioning assembly is installed on the carrier board 12, and the positioning control of the mai...

Embodiment 2

[0027] On the basis of the above-mentioned embodiments of this embodiment, the positioning assembly is further explained, wherein, the positioning assembly includes a guide wheel 28 and a sliding rod 22; Elastically installed between the carrier plate 12, three groups of sliding rods 22 are evenly arranged on the carrier plate 12 along the circumference of the through hole on the carrier plate 12; specifically, when the main shaft 15 passes through the through hole, the three groups The rollers can effectively realize the positioning of the main shaft 15, thereby effectively improving the actual use effect of the device.

[0028]The working principle of the present invention is: during the use of the device, the electromagnet 16 is adsorbed on the end of the main shaft 15, thereby realizing the relative fixation between the main shaft 15 and the pull cord 17; Rotate, and then realize the lifting of the main shaft 15; Specifically, on the inner wall of the quenching box 4, a nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com