Bearing ring and sleeve part automatic quenching machine based on robot control

A bearing ring and robot technology, applied in the direction of heat treatment process control, manufacturing tools, furnace types, etc., can solve the problems of high production cost, high labor intensity of manual operation, and high labor intensity, so as to promote the lean production process, avoid Leakage of quenching liquid and the effect of improving quenching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

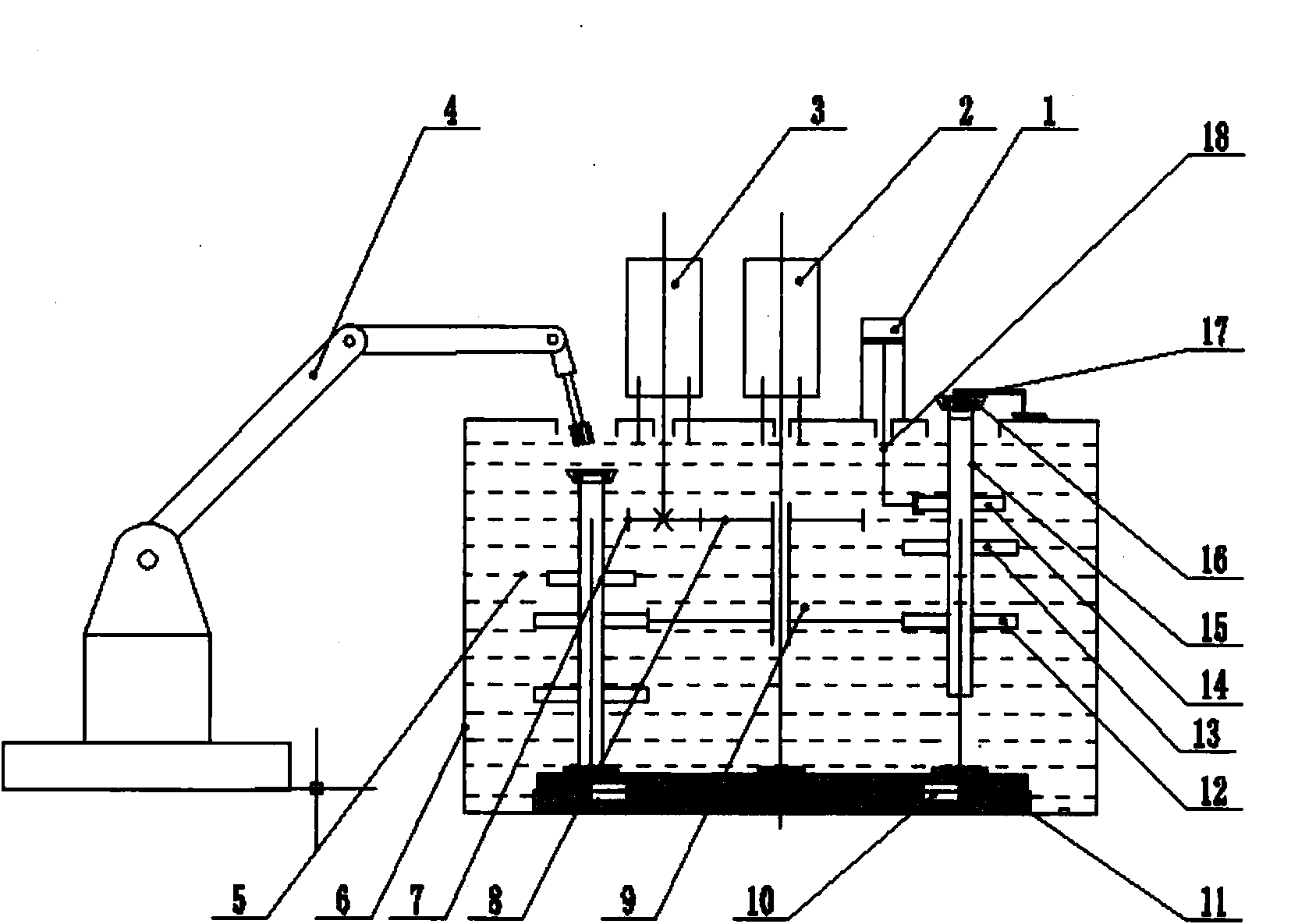

[0028] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

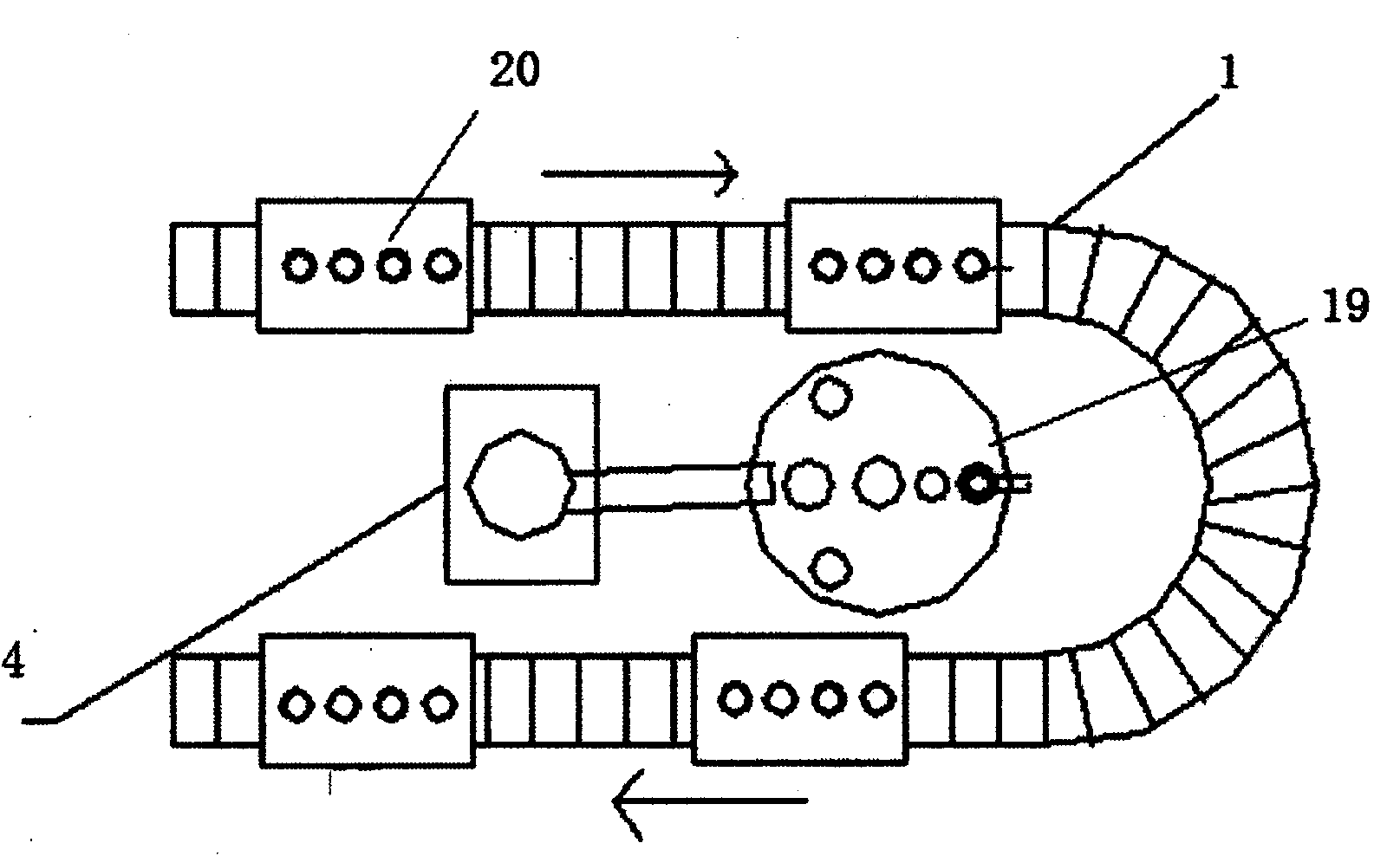

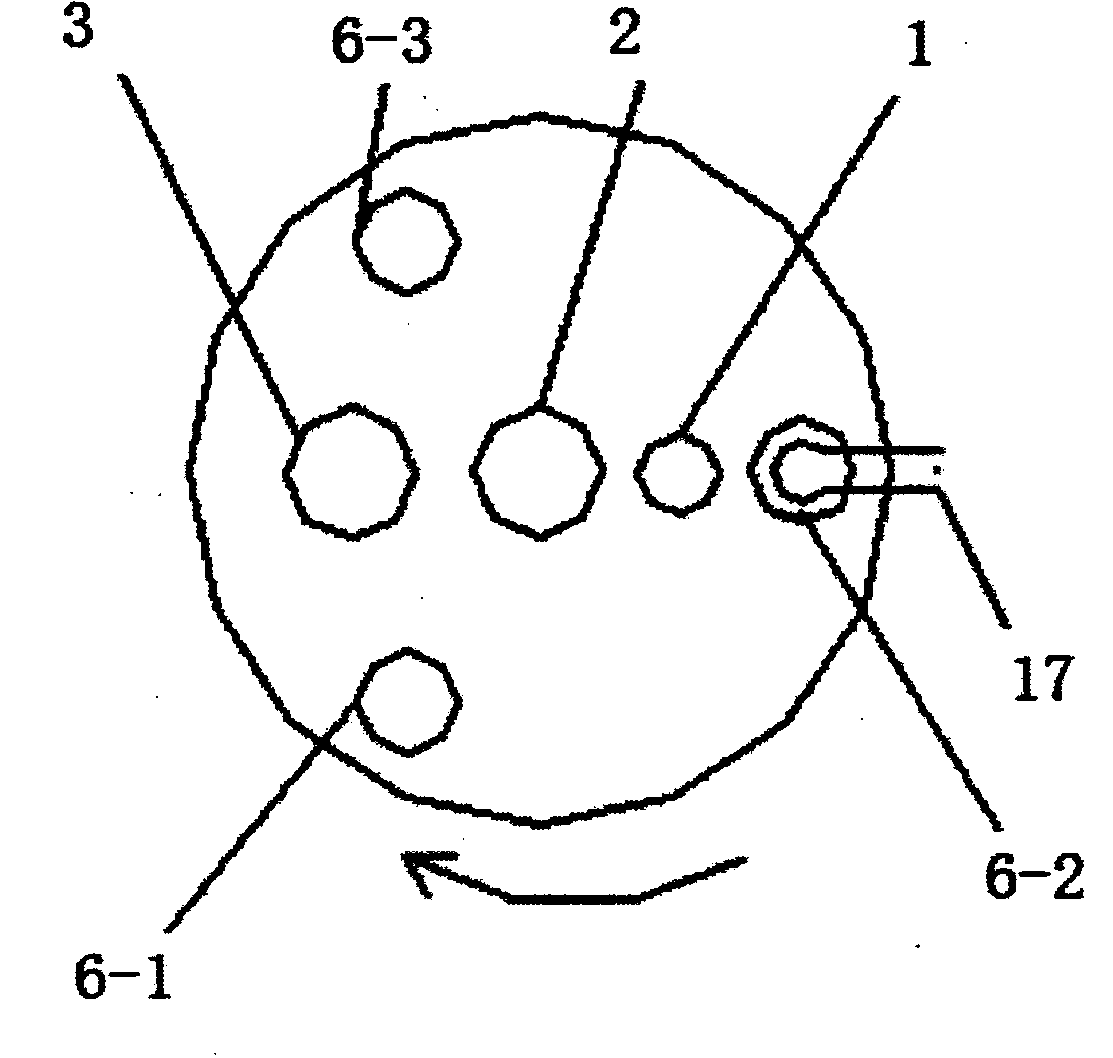

[0029] Such as figure 1 As shown, the present invention provides a robot-based automatic quenching machine for bearing rings and sleeve parts, which includes three subsystems in total, which are RGV automatic guided transport vehicle system 1, robot 4, quenching equipment and control sub-systems. System 19, wherein:

[0030] The parts 16 to be processed (in this embodiment, the parts 16 are bearings) are placed on the RGV trolley 20 of the RGV automatic guided vehicle system 1, and the automatic transportation of the parts to be processed 16 is realized by the RGV automatic guided vehicle system 1;

[0031] The robot 4 grabs the bearing to be processed on the RGV trolley 20 and puts it into the quenching equipment and the control subsystem 19. The quenching equipment and the control subsystem 19 complete the heating and quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com