Double-station die cutting equipment for machining printed label roll

A double-station, label roll technology, applied in metal processing and other directions, can solve the problems of poor uniformity of peripheral cutting, affect product quality and aesthetics, and decline in cutting quality, so as to avoid inconsistent die-cutting quality and improve die-cutting processing Quality, improvement of production efficiency and the effect of production and processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

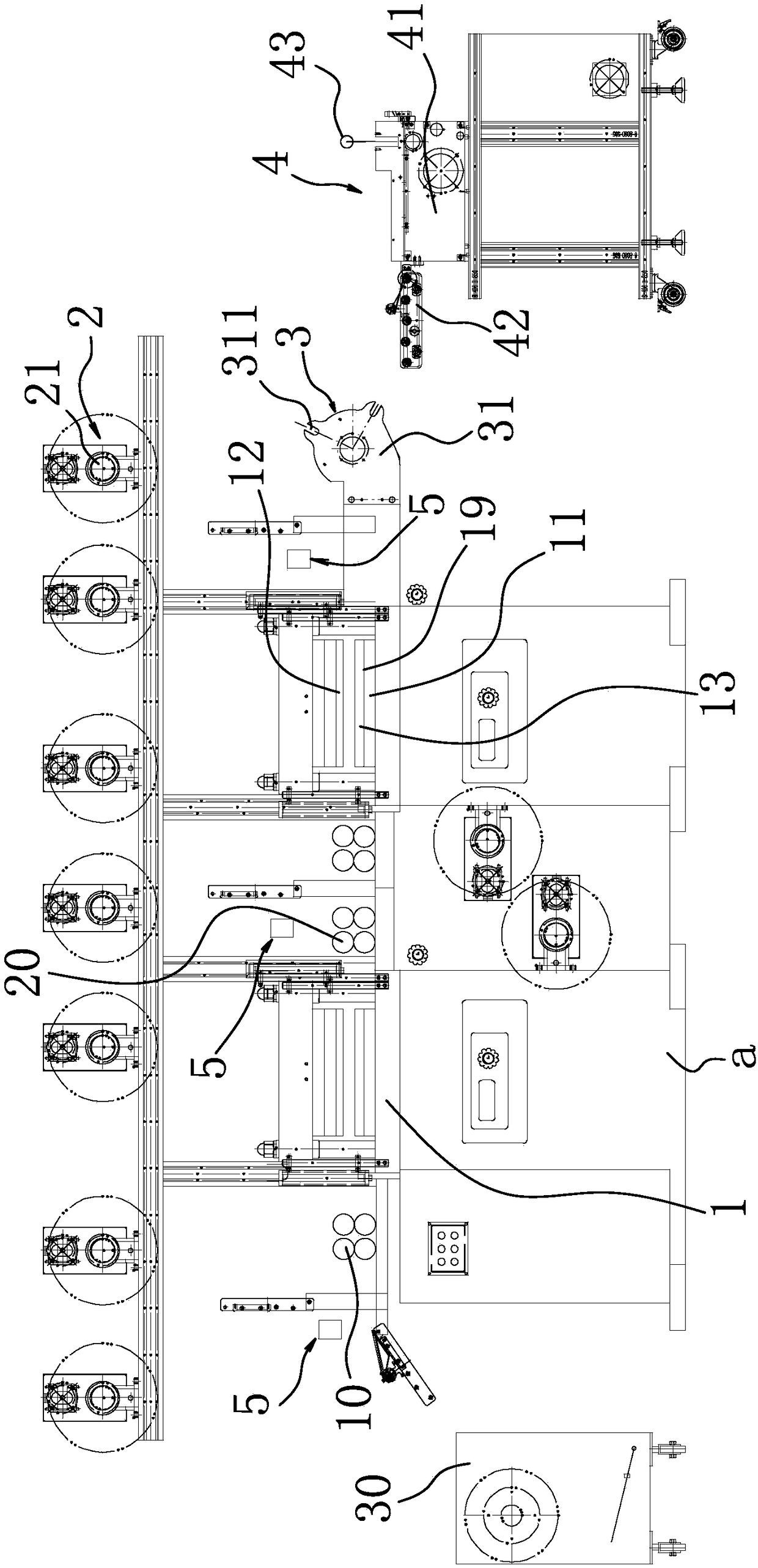

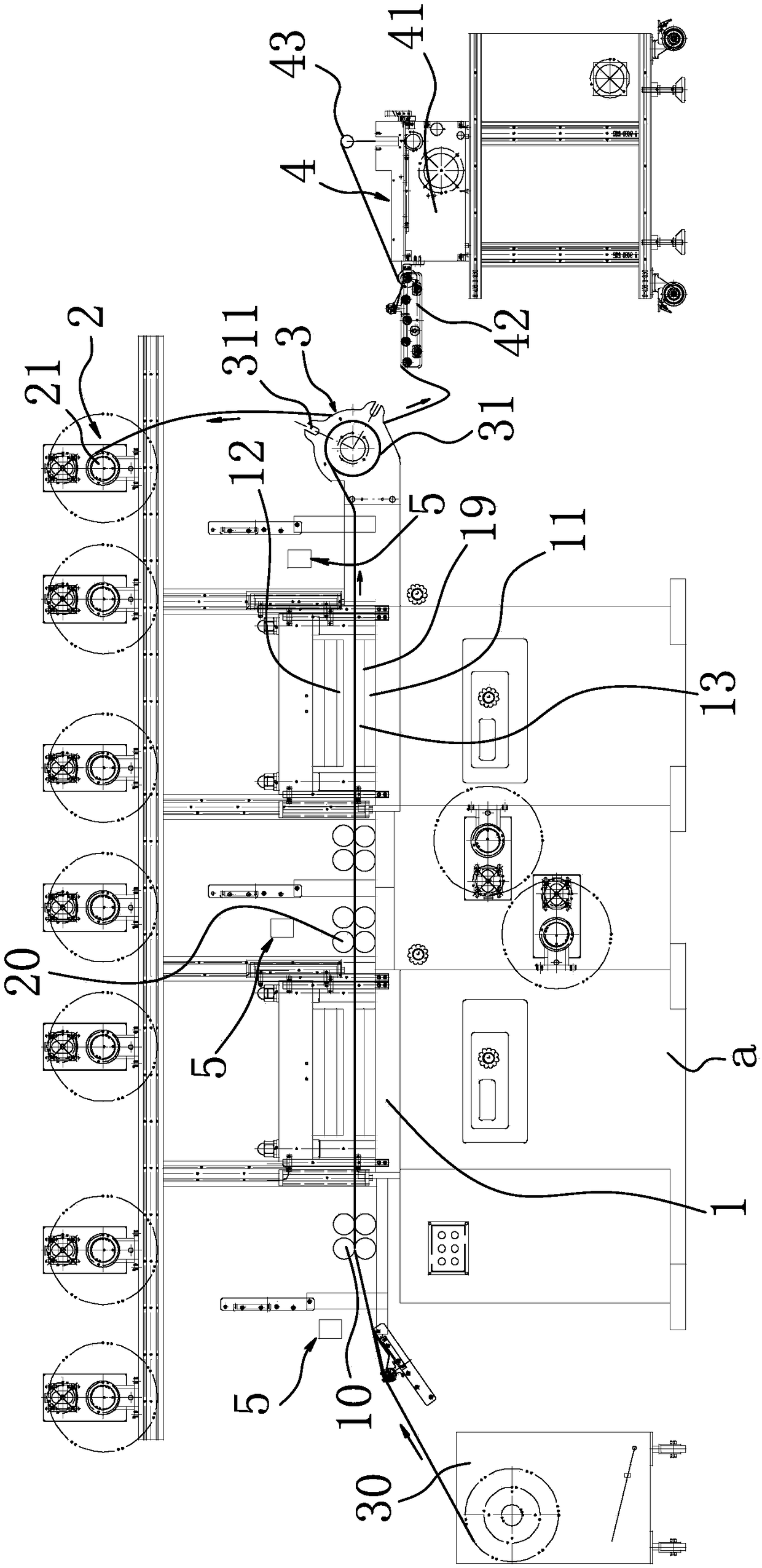

[0071] like Figure 1-5 As shown, the double-station die-cutting equipment for processing and printing label rolls includes a frame a with a conveying platform 1. One end of the conveying platform 1 is the feeding end, and the other end is the discharging end. Unwinding and rewinding device above platform 1.

[0072] Two die-cutting lower dies 11 arranged at intervals are arranged on the conveying platform 1, and two positioning gaps are arranged in the middle of the conveying platform 1, and the die-cutting lower dies 11 are fixed in the positioning gaps one by one.

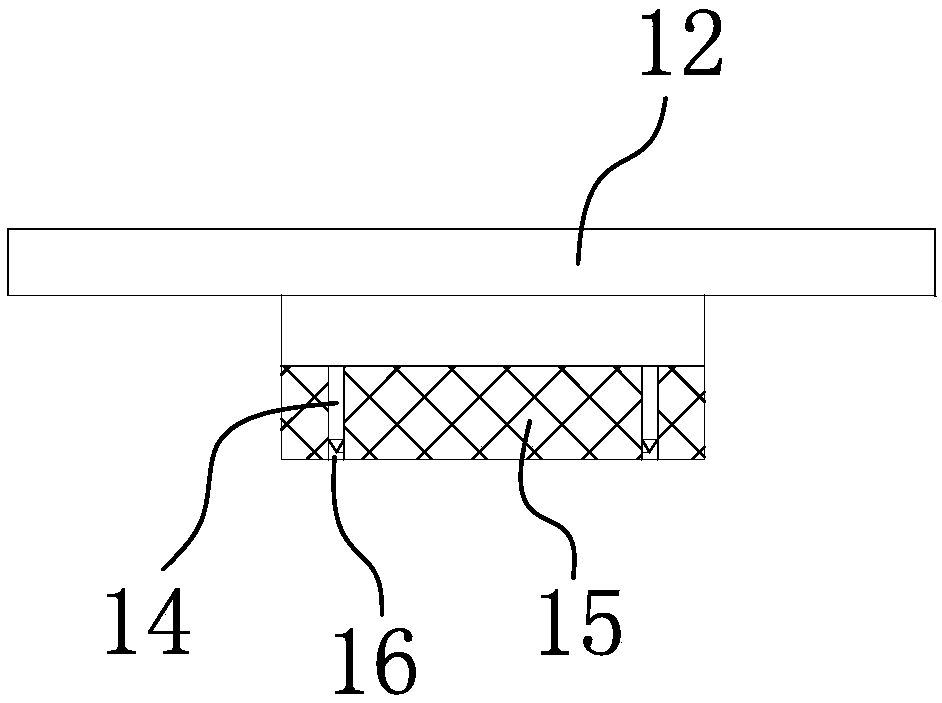

[0073] There are symmetrically arranged L-shaped briquetting blocks on both sides of the positioning gap, and positioning gaps for pressing the bending part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com