Microwave pest killing method for grain products such as rice, beans, wheat

A technology for grains and rice, applied in the direction of heating and preserving seeds, etc., can solve the problems of bursting waist, discoloration, water loss, puffing, ripening, incomplete killing of insect eggs, pollution, etc., to improve production and processing speed and product quality. , to achieve continuous production, reduce the effect of fumigation pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

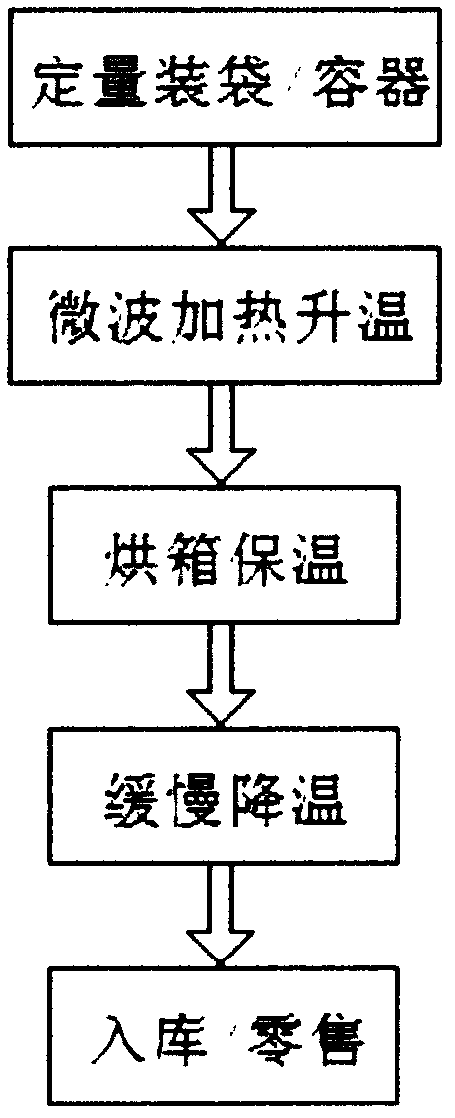

[0031] A method for killing adults, larvae and eggs in boxed rice by microwaves, comprising the following steps:

[0032] (1) Take a batch of plastic boxes with a capacity of 1-25 kg. The boxes can withstand a temperature of 85°C. Open 20-50 pinholes on the box cover and around them as air holes, and then weigh the rice into the box in equal parts, and then cover;

[0033] When the frequency of the microwave equipment in the system is 2450MHz, the height of the rice material is controlled at 8cm, and when the frequency of the microwave equipment is 915MHz, the height of the rice material is controlled at 16cm;

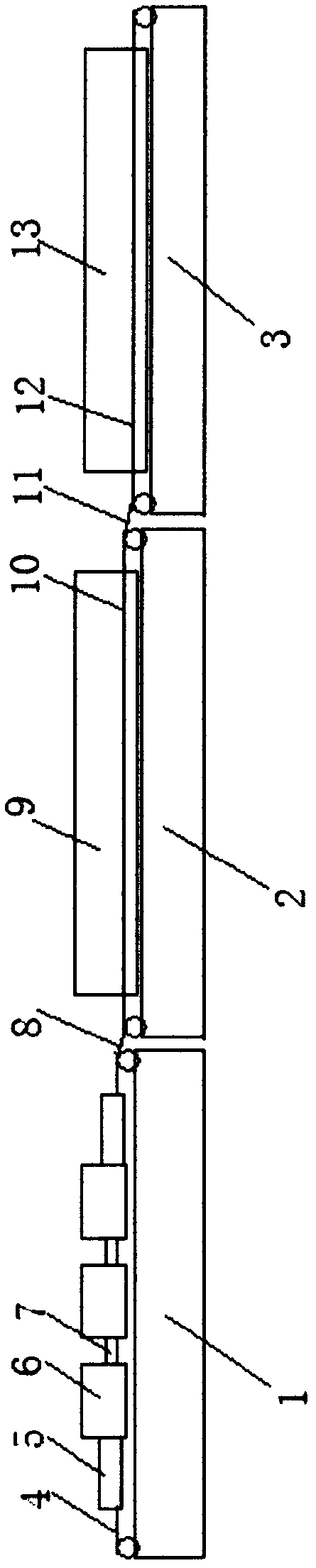

[0034] (2) Turn on the microwave insecticidal production line system, and adjust the microwave equipment 1, heat preservation oven equipment 2, and cooling channel equipment 3 to the working state;

[0035] (3) Open the box-type industrial microwave oven 1, put the boxed rice into the microwave conveyor belt 4 in sequence, adjust the microwave power and assist the hot...

Embodiment 2

[0040] The method for killing adults, larvae and worm eggs in bagged rice by microwave comprises the following steps:

[0041] (1) Get a batch of woven bags with a capacity of 1-25 kg. The box can withstand a temperature of 85° C., then weigh the rice into the bags in equal parts, and then seal them;

[0042] When the frequency of the microwave equipment in the system is 2450MHz, the height of the rice material is controlled at 8cm, and when the frequency of the microwave equipment is 915MHz, the height of the rice material is controlled at 16cm;

[0043] (2) Turn on the microwave insecticidal production line system, and adjust the microwave equipment 1, heat preservation oven equipment 2, and cooling channel equipment 3 to the working state;

[0044] (3) Open the box-type industrial microwave oven 1, put the bagged rice into the microwave conveyor belt 4 in turn, adjust the microwave power and assist the hot air to heat the rice, and control the microwave heating of the rice ...

Embodiment 3

[0049] The method for killing adults, larvae and worm eggs in bagged rice by microwaves comprises the following steps:

[0050] (1) Take a batch of plastic bags with a capacity of 1-25 kg. The bags can withstand a temperature of 100 ° C. Prick 10-20 needle holes on the bags as air holes, then weigh the rice and put it into the bags in equal parts, and then seal them;

[0051] When the frequency of the microwave equipment in the system is 2450MHz, the height of the rice material is controlled at 8cm, and when the frequency of the microwave equipment is 915MHz, the height of the rice material is controlled at 16cm;

[0052] (2) Turn on the microwave insecticide production line system, and adjust the industrial box-type microwave equipment 1, heat preservation oven equipment 2, and cooling channel equipment 3 to the working state;

[0053] (3) Open the box-type industrial microwave oven 1, put the bagged rice into the microwave conveyor belt 4 in turn, adjust the microwave power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com