Paper product processing production line with heating and edge cutting functions

A paper product and production line technology, applied in the field of plant fiber product processing, can solve problems such as unreasonable, low processing efficiency of paper products, and long distribution of production lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

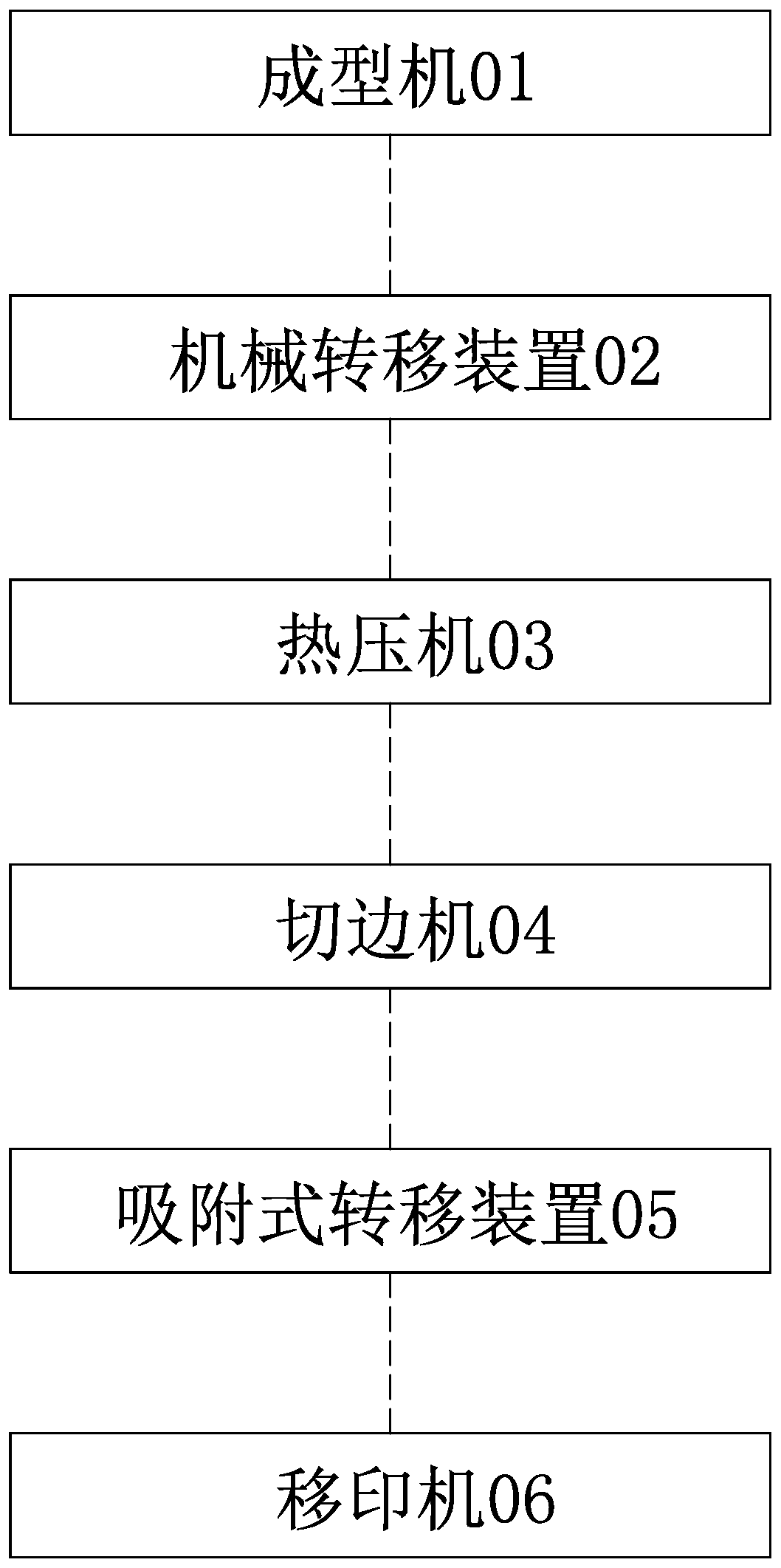

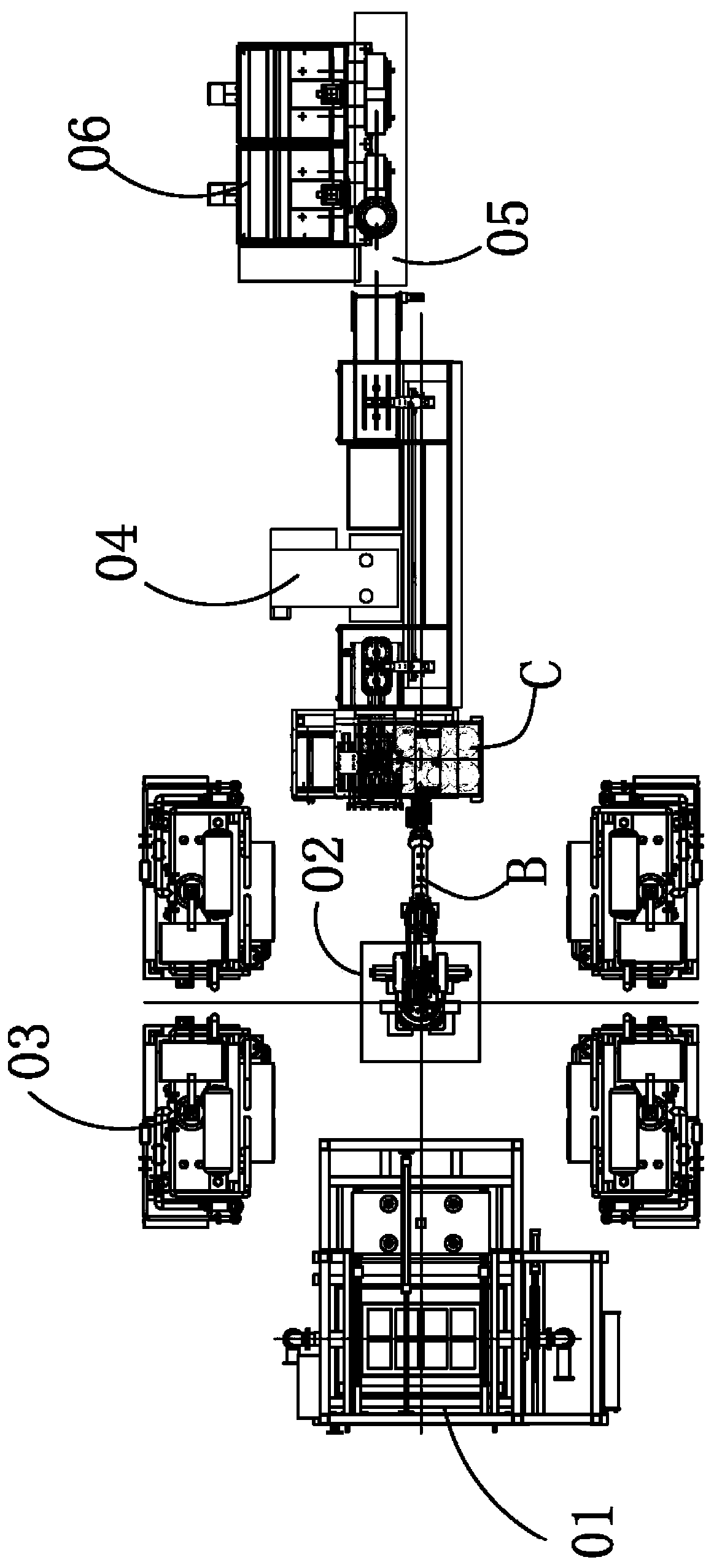

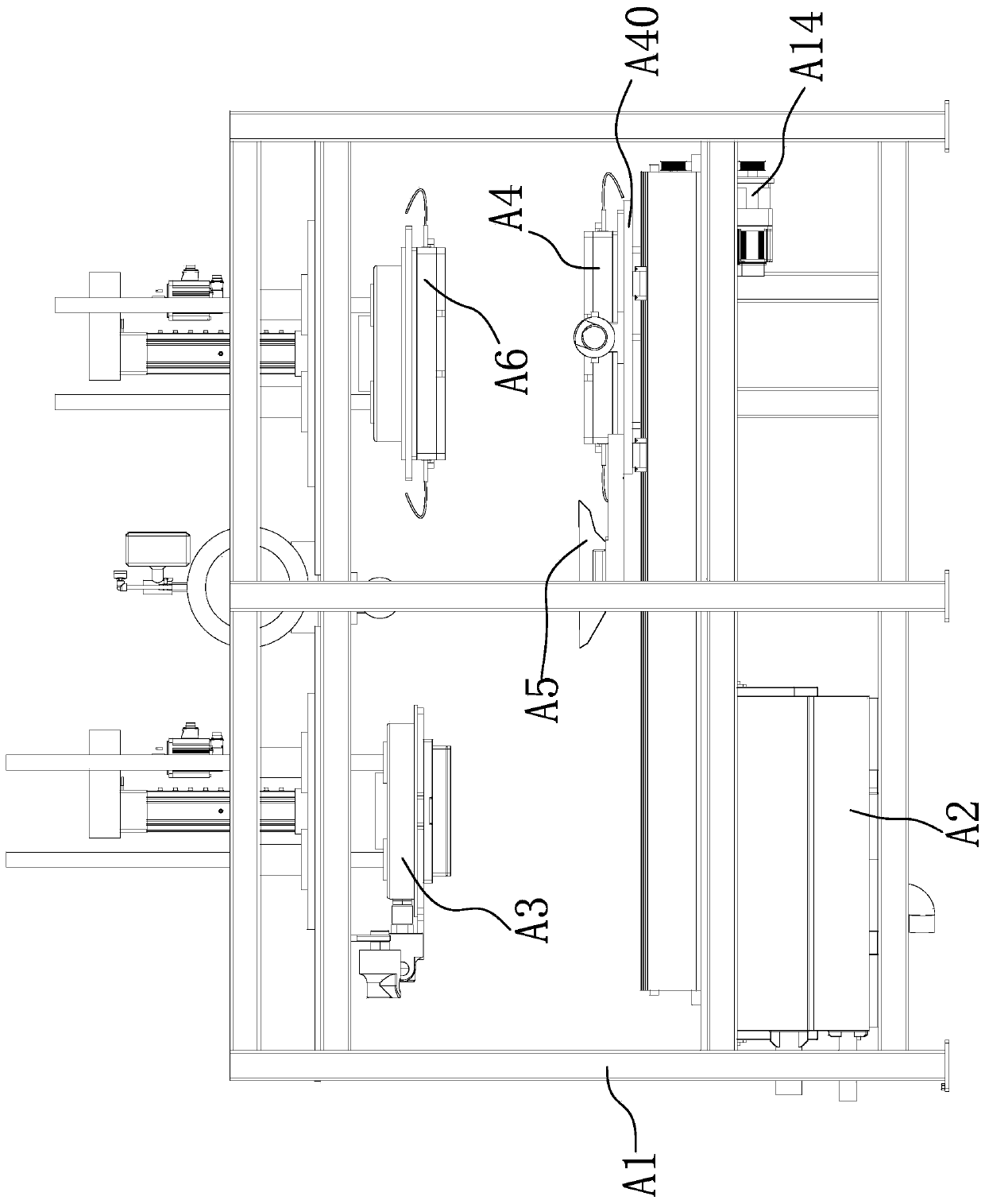

[0116] like figure 1 and figure 2 As shown, the paper product processing production line with heating and trimming functions includes: forming machine 01, at least one forming machine, the forming machine extrudes the slurry, and further, the forming machine is for suction pulp forming machine, the back suction pulp forming machine adopts back suction pulp and performs one-time extrusion heating molding and second extrusion heating molding on the slurry in sequence;

[0117] Mechanical transfer device 02, at least one mechanical transfer device will obtain and transfer the paper product blank formed by the suction pulp forming machine;

[0118] Hot press machine 03, at least one hot press machine and the mechanical transfer device transfers and releases the obtained paper product blank on the hot press machine, and the hot press machine overheats the paper product blank;

[0119] Edge trimming machine 04, the mechanical transfer device obtains and transfers the paper produc...

Embodiment 2

[0252] The structure and principle of this embodiment are the same as that of Embodiment 1, the difference is that: the suction pulp forming machine, the mechanical transfer device and the trimming machine are located on the same straight line, and the total number of the hot presses is 1-8 Taiwan, and the hot press is distributed on either side of the same straight-line suction pulp forming machine and / or mechanical transfer device.

Embodiment 3

[0254] The structure and principle of this embodiment are the same as those of Embodiment 1, the difference lies in:

[0255] like Figure 14 Shown, wet blank transfer mold C1 comprises base plate-C11, is provided with 1-12 vacuum-pumping hole-C12 on base plate-C11, is provided with wet blank mold C13 on the side of base plate-C11 away from product transfer mold C2, in wet The side of the base mold C13 close to the bottom plate C11 is provided with an air chamber C14 equal in number to the vacuum hole C12, and one air chamber C14 communicates with a vacuum hole C12. On the side of the wet blank mold C13 away from the bottom plate C11 The above-mentioned wet billet adsorption pockets C10 are provided. The number of wet billet adsorption pockets C10 is equal to the number of air chambers C14, and each wet billet adsorption recess C10 communicates with an air chamber C14 through several air-permeable small holes C15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com