Cleaning device for semiconductor product production and processing

A cleaning device and semiconductor technology, applied in the directions of dry gas arrangement, cleaning method using tools, cleaning method using liquid, etc., can solve the problems of time-consuming and laborious cleaning effect, etc., to improve processing efficiency and quality, simple operation, and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

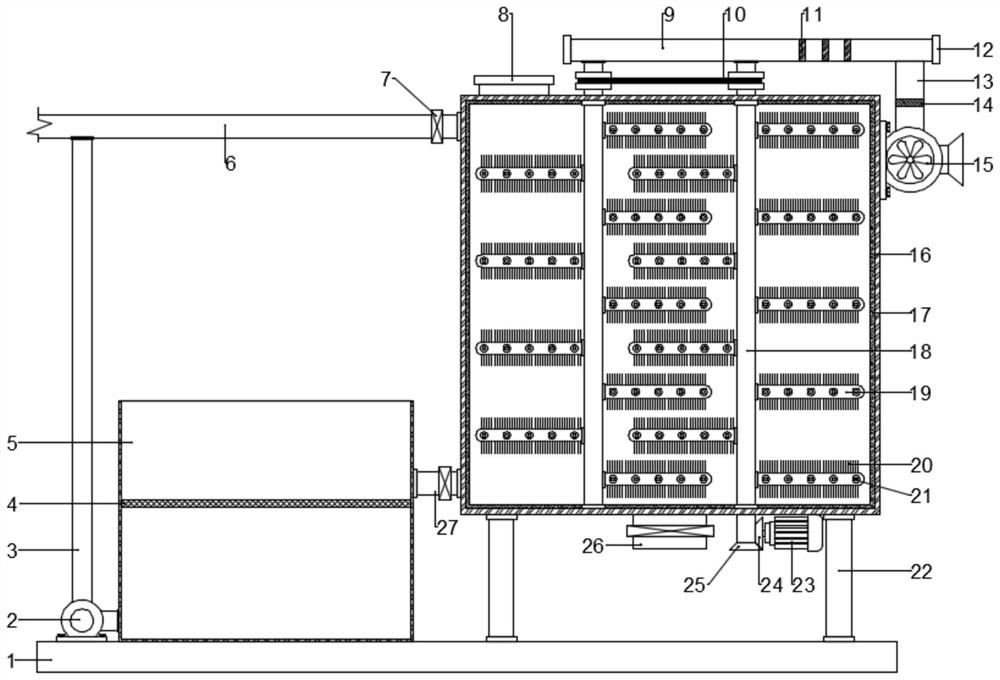

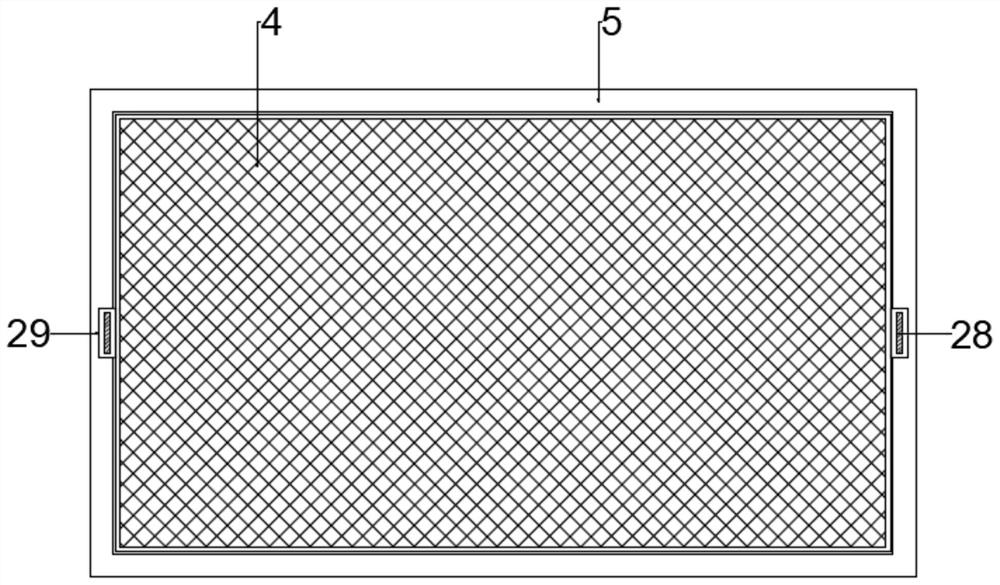

[0021] see figure 1 and figure 2 , in an embodiment of the present invention, a cleaning device for production and processing of semiconductor products includes a carrying base 1, a cleaning unit and a filtrate unit, the cleaning unit and the filtrate unit are both arranged on the carrying base 1, and the cleaning unit includes a cleaning box 16 and The brushing assembly, the brushing assembly is arranged in the cleaning box 16, the cleaning unit is used to clean the semiconductor products, and the filtrate unit is used to filter and purify the used cleaning solution and then transport it to the cleaning box 16 for practical use to achieve the purpose of recycling, and then Reduce production costs of enterprises.

[0022] The cleaning box 16 is fixed on the top of the bearing base 1 through a plurality of support rods 22. The top of the cleaning box 16 is provided with a product delivery port 8, and the bottom of the cleaning box 16 is provided with a product outlet 26 for t...

Embodiment 2

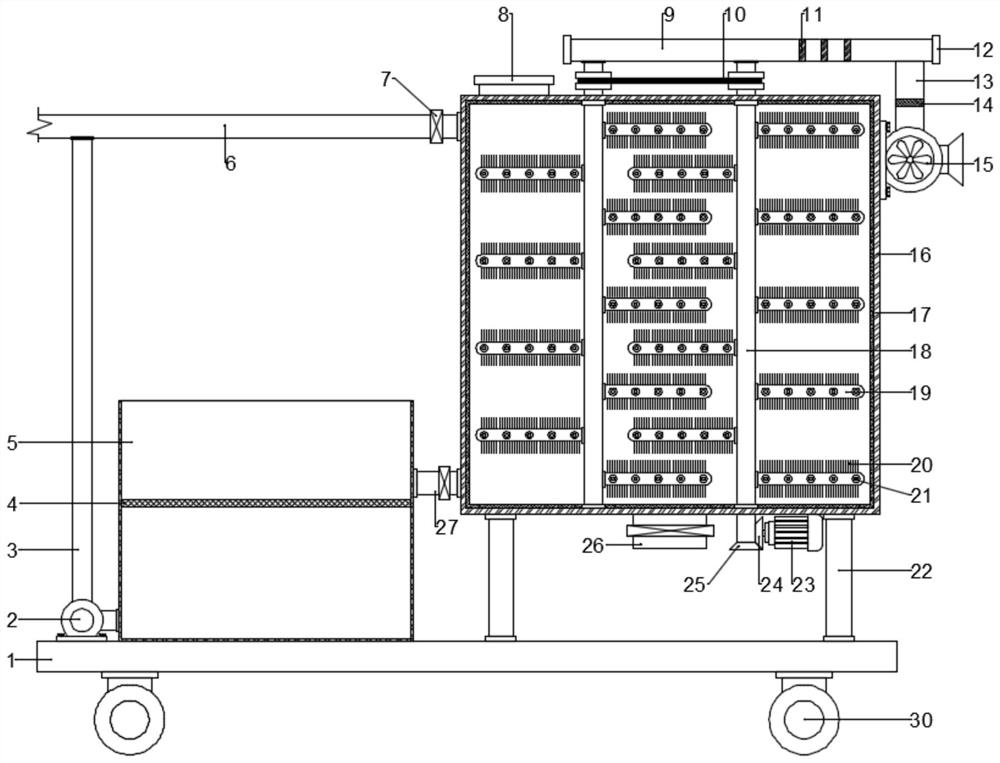

[0029] see image 3 The difference between the embodiment of the present invention and embodiment 1 is that, further, in order to facilitate the movement of the device, a plurality of moving wheels 30 are symmetrically arranged on the bottom of the bearing base 1, and the moving wheels 30 are self-locking rollers, and the staff The device can be easily and conveniently moved through the moving wheels 30, which is simple and trouble-free, convenient and practical.

[0030]The working principle of the present invention is: when the present invention is in use, first put the semiconductor product into the cleaning box 16 through the product delivery port 8, then open the liquid inlet valve 7 and inject an appropriate amount of cleaning liquid into the cleaning box 16, and then start the blower 15 and a servo motor 23, the servo motor 23 drives two rotating tubes 18 to rotate so that multiple turning tubes 19 stir the semiconductor product and make it squeeze and contact with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com