Mechanical part surface polishing device

A technology for surface polishing and mechanical parts, applied in the field of mechanical parts processing, can solve the problems of affecting the processing efficiency of mechanical parts, poor polishing effect, time-consuming and laborious, etc., achieve good economic benefits and practical significance, reasonable device structure layout, and easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

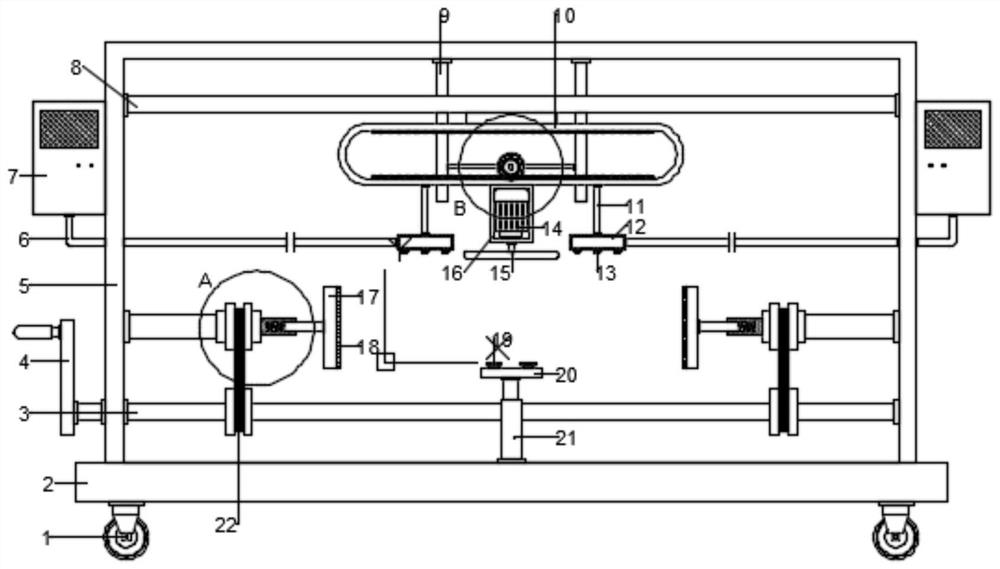

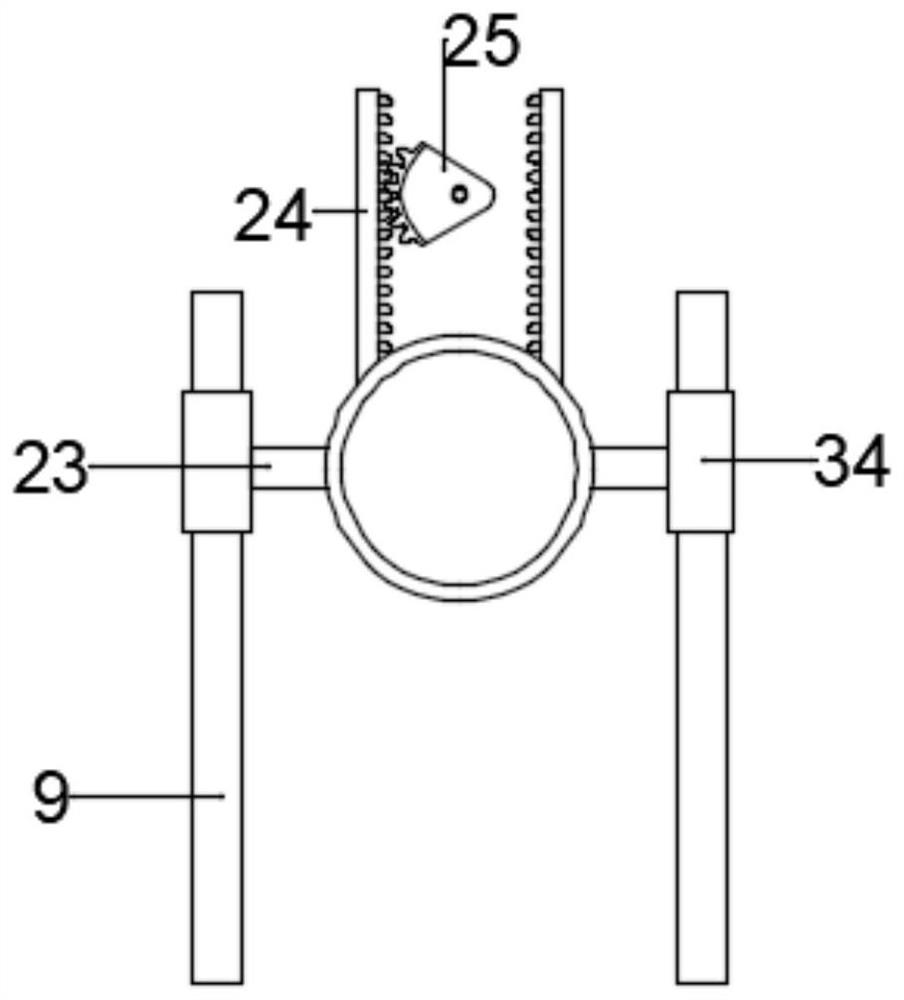

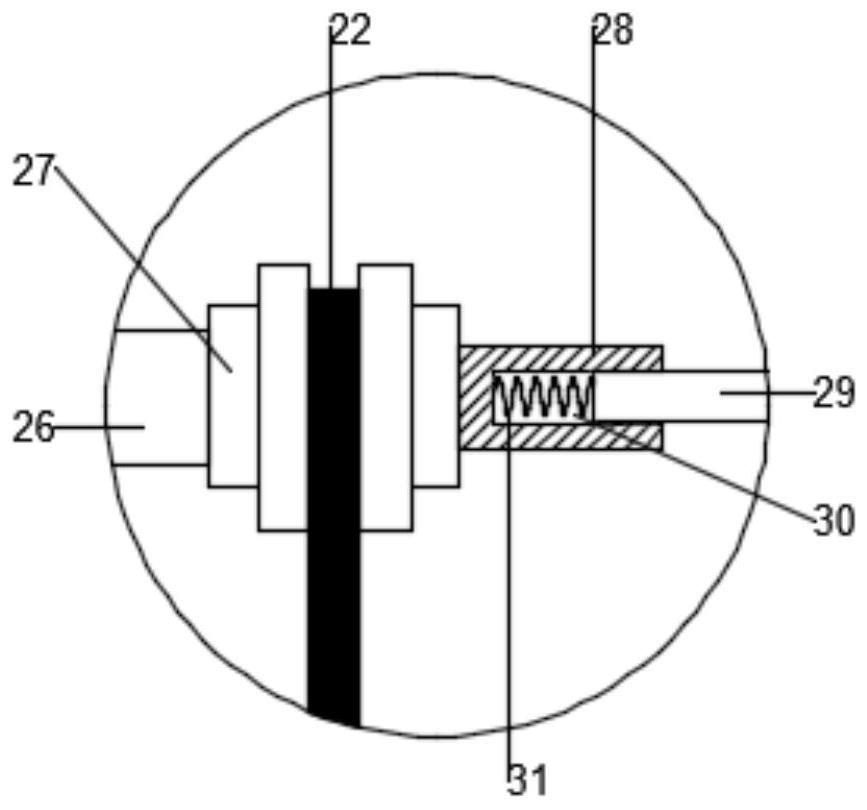

[0023] see Figure 1-5 , in an embodiment of the present invention, a mechanical accessory surface polishing device includes a base 2 and a U-shaped frame 5, the U-shaped frame 5 is fixed on the base 2, and the left and right inner walls of the U-shaped frame 5 are provided with The mechanical parts to be polished are clamped and fixed. The clamping assembly includes an insert sleeve 26 and an externally threaded telescopic rod 28. The externally threaded telescopic rod 28 is slidably inserted into the insert sleeve 26. The junction is provided with an internally threaded swivel 27. The internally threaded swivel 27 and the insertion sleeve 26 are in a rotational connection, and the externally threaded telescopic rod 28 is an adapted threaded connection. The externally threaded telescopic rod 28 is far away from the socket. The end portion of the cylinder 26 is provided with a slot 30, and an insertion rod 29 is slidably inserted in the slot 30. An extrusion spring 31 is arran...

Embodiment 2

[0030]Further, since polishing will produce a large amount of dust, in order to avoid the dust floating in the remote control and being accidentally sucked by the human body, which will damage health, two support rods are passed under the waist-shaped movable frame 10 and on the left and right sides of the polishing wheel 15. 11 is symmetrically provided with two dust collection boxes 12, and the bottoms of the two dust collection boxes 12 are evenly embedded with dust suction nozzles 13, and the left and right sides of the U-shaped frame 5 are fixed with vacuum cleaners 7, and the dust collection of the two vacuum cleaners 7 Both ends are fixedly connected with vacuum hoses 6, and the ends of the two vacuum hoses 6 away from the vacuum cleaner 7 extend to the two dust collection boxes 12 respectively, and the dust generated by polishing is quickly and efficiently absorbed by the vacuum cleaner 7 to avoid It floats into the air and endangers people's health.

[0031] The worki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com