Automatic loading and unloading device of silk cloth binding machine for foams of bases of wine bottles

A technology of automatic loading and unloading and silk fabric machine, which is applied in packaging and other directions, and can solve the problems of difficult positioning and transportation of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

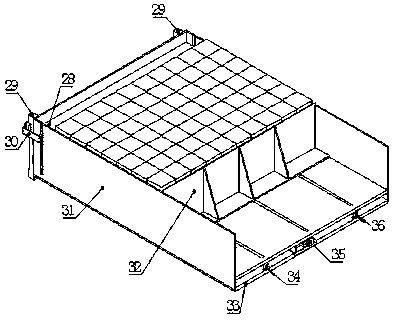

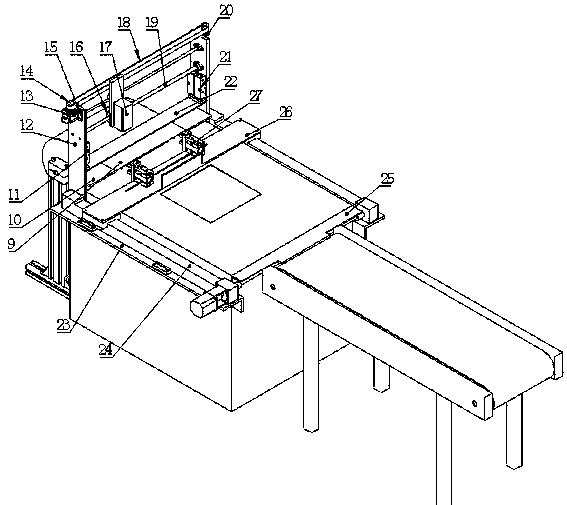

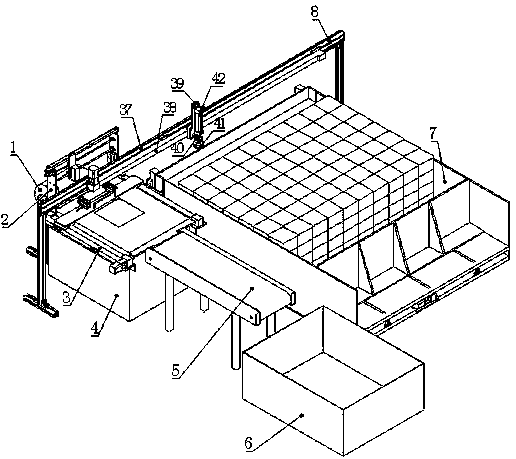

[0017] refer to Figure 1 , silk feeding frame 1, silk tie machine 4, feeding conveyor belt 5, finished product storage bin 6, foam material storage mechanism 7, foam material delivery mechanism 8 is fixed on the ground with a certain positional relationship, cloth cutting mechanism 2 and The silk cloth positioning mechanism 3 is fixed on the silk tie machine 4, and a cloth wheel is fixed on the silk cloth feeding frame 1, and a large amount of silk cloth is wound on the cloth wheel, which can be directly disassembled and replaced by a worker. In the initial state, Silk cloth is positioned on carrying silk plate 10, and the piston rod of A silk cloth pressing cylinder 11 and B silk cloth pressing cylinder 21 is in extended state, and silk cloth pressing plate 22 compresses silk cloth, and silk cloth cutting head 17 is in cutting. One end of the cloth mechanism frame 12, the cloth clamping pneumatic finger 27 is fixed on the feeding plate 26, and the silk cloth end on the silk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com