Control method of full-life periodical processing precision of mould

A technology with full life cycle and processing precision, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increasing the number of trial molds, increasing mold manufacturing time, and knife collision, so as to improve mold manufacturing accuracy and improve manufacturing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

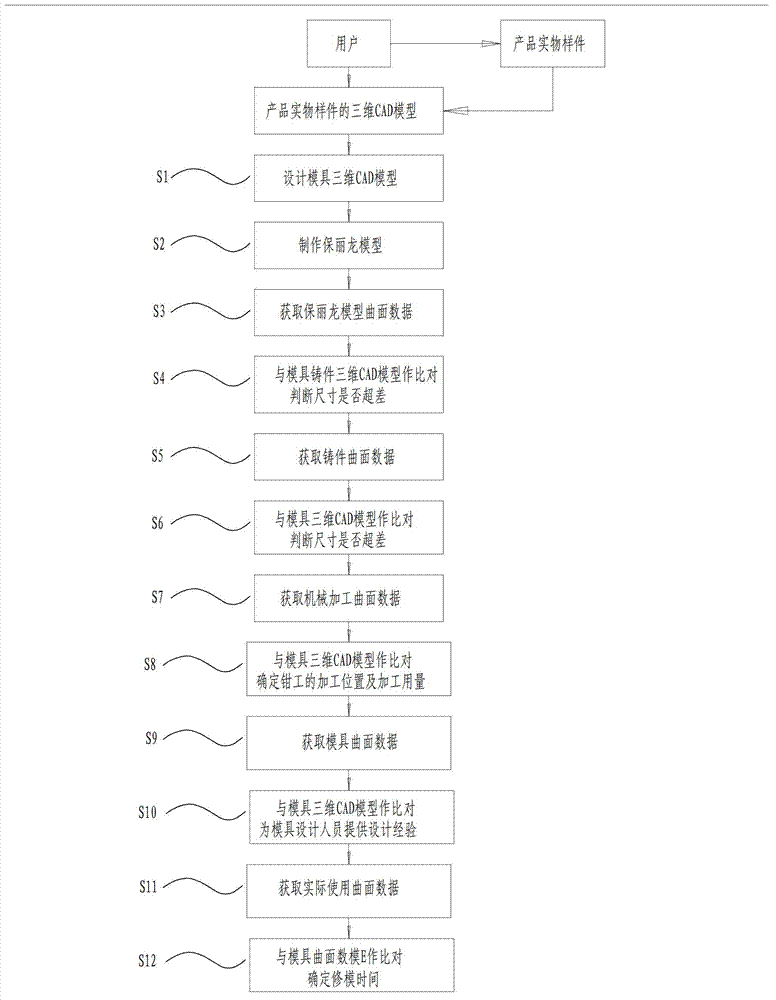

[0044] A method for controlling the processing accuracy of a mold in its entire life cycle. The method is a method for controlling the processing accuracy of a mold in its entire life cycle. The entire life cycle of a mold includes measurement of product samples, mold manufacturing process, and mold use process. And the mold repair process, the following is based on the attached figure 1 , to illustrate the specific steps of the method:

[0045] S1. Design mold 3D CAD model:

[0046]Use the measuring device - self-positioning handheld non-contact 3D laser scanner to scan the product sample provided by the user, obtain the product sample data, and import the product sample data into the point cloud data processing software system through the computer to convert it into The digital model A is obtained from the virtual three-dimensional surface of the product sample, and the three-dimensional CAD (abbreviation for Computer Aided Design, translated as computer-aided design) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com