Method for estimating error in numerical control processing

A machining method and error estimation technology, applied in the precision control field of CNC machining, can solve problems such as large difference, affecting machining accuracy, high error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] see Figure 5 , the error estimation method in NC machining, the operation steps are as follows: (1) modeling: generate solid model in UG or Solidworks 3D modeling software; (2) NC code generation: set tool in CAM software, generate processing method parameters Tool processing path, post-processing to generate NC code; (3) Obtain tool center coordinates: process NC code to obtain tool center coordinates; (4) Tangent vector determination: determine the unit tangent vector of each point according to tool center coordinates, (5) Calculate the actual processing curve: calculate the actual processing curve trajectory by comprehensively calculating the tool radius, tool center coordinates, and determined tangent vector conditions of each point; (6) Calculate the bow height error: use arc approximation estimation between two points on the actual curve trajectory Bow height error.

Embodiment 2

[0043] see Figure 1-5 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0044] The step (1) modeling: generate a solid model in UG or Solidworks 3D modeling software, select the CAM software according to the shape of the solid model and import it into the CAM software

[0045] The step (2) NC code generation: in the CAM software, according to the corresponding workpiece model, select the tool and processing method, set the corresponding parameters in the processing method tab, generate the tool path, and then generate the NC code by the corresponding post-processor.

[0046] The step (3) obtains the coordinates of the tool center: according to the generated NC code, compile a program for processing, remove the tool information in the NC code, and obtain the X, Y, Z coordinates that are the coordinates of the tool center by removing the tool information and processing method .

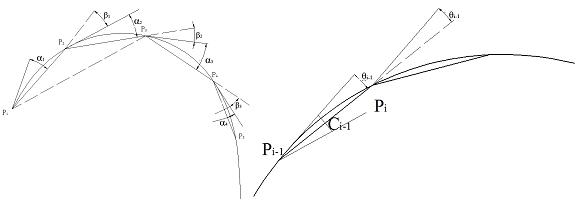

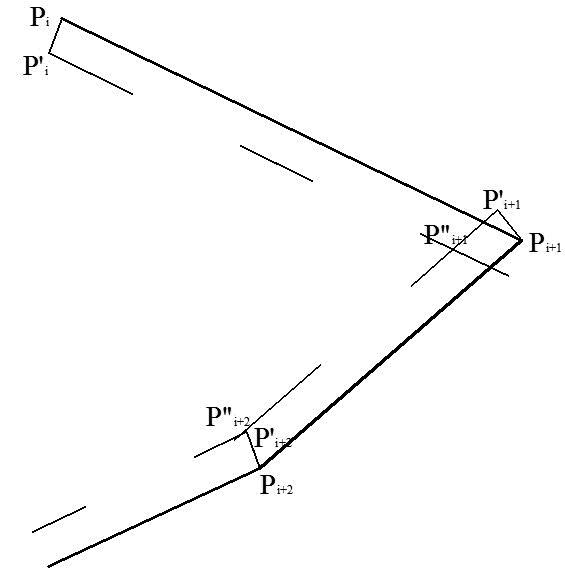

[0047] The step (4) tangent vector dete...

Embodiment 3

[0053] This error estimation method in NC machining aims at the problems existing in the current error estimation method, based on the original method, firstly, according to the tool center coordinates obtained from the NC code derived from the CAM software, the unit tangent vector of each point is determined, and then combined with The radius of the tool, the coordinates of the center of the tool, and the determined tangent vectors of each point are calculated to obtain the actual machining curve trajectory. Finally, according to the calculated actual curve trajectory, the arc is used to approximate the small straight line segment and the bow height error is calculated. The implementation flowchart of this method, as Figure 5 shown.

[0054] Establish a solid model in 3D modeling software such as UG or Solidworks, import it into MasterCAM, select the appropriate processing method and tool, set the machining allowance, truncation error, etc. to generate the tool path trajecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com