Refrigeration house temperature feedforward-fuzzy control system based on dynamic load variation and control method

An energy-saving control system and load technology, applied in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problems of control lag, poor accuracy, and failure to take cooling capacity into account, and achieve control effects Improve and control the effect of precise accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

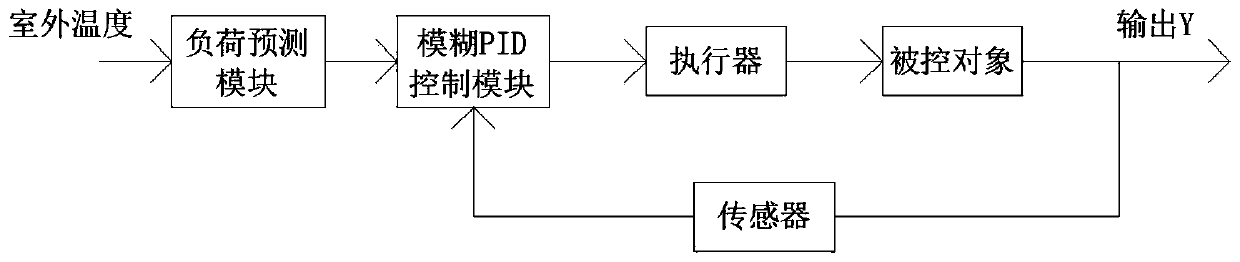

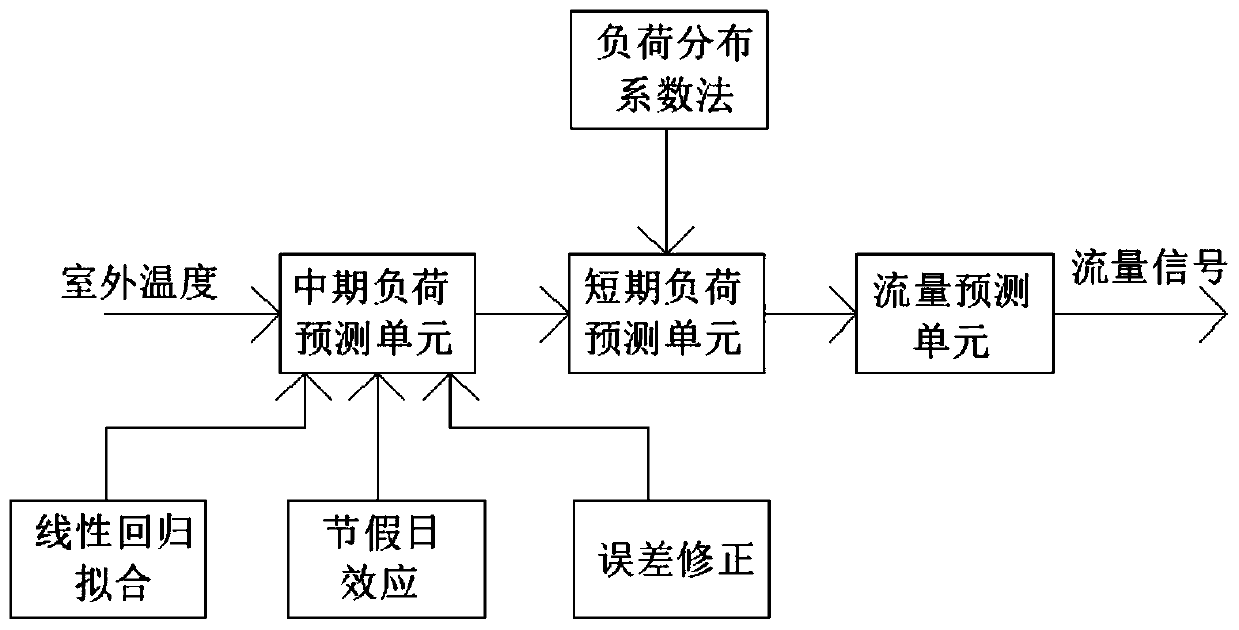

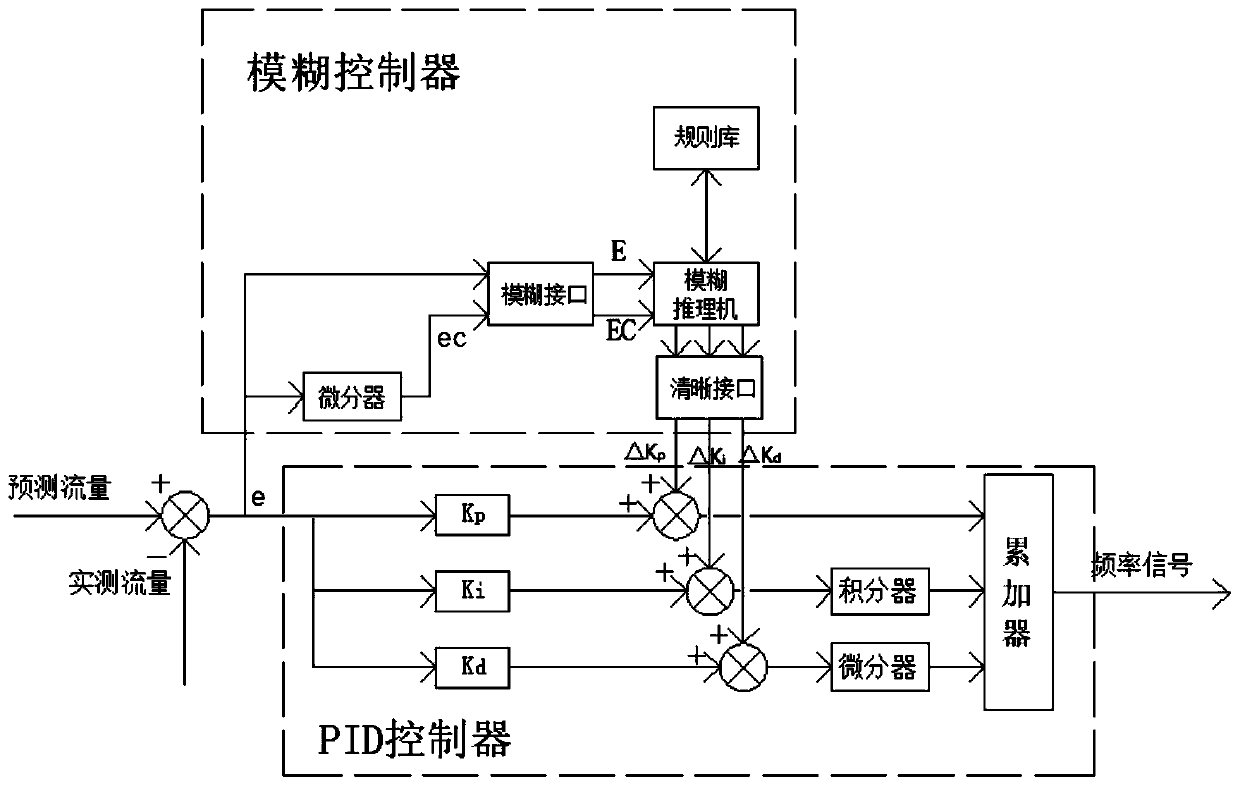

[0039] like figure 1 A central air-conditioning chilled water control system based on load forecasting is shown, and its control module includes: including a load forecasting module, a fuzzy PID control module, an actuator, a controlled object and a sensor. The load module calculates the hourly load of the building through outdoor environmental parameters and historical data, and converts it into predicted flow and sends it to the fuzzy PID controller. The fuzzy PID controller calculates the difference e between the predicted flow and the actual flow, and calculates the difference e through the fuzzy reasoner and PID controller, outputs the frequency signal to the actuator, and the actuator controls the pump frequency according to the output signal , so as to complete the dynamic adjustment of the flow.

[0040] l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com