Preparation method for coatings of medical supplies and products thereof

A technology of medical supplies and coatings, applied in coatings, metal material coating processes, gaseous chemical plating, etc., can solve problems such as failure of disinfection and sterilization, difficulty in cleaning, uneven coating thickness, etc., and achieve a tight and firm combination , wide temperature range, good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

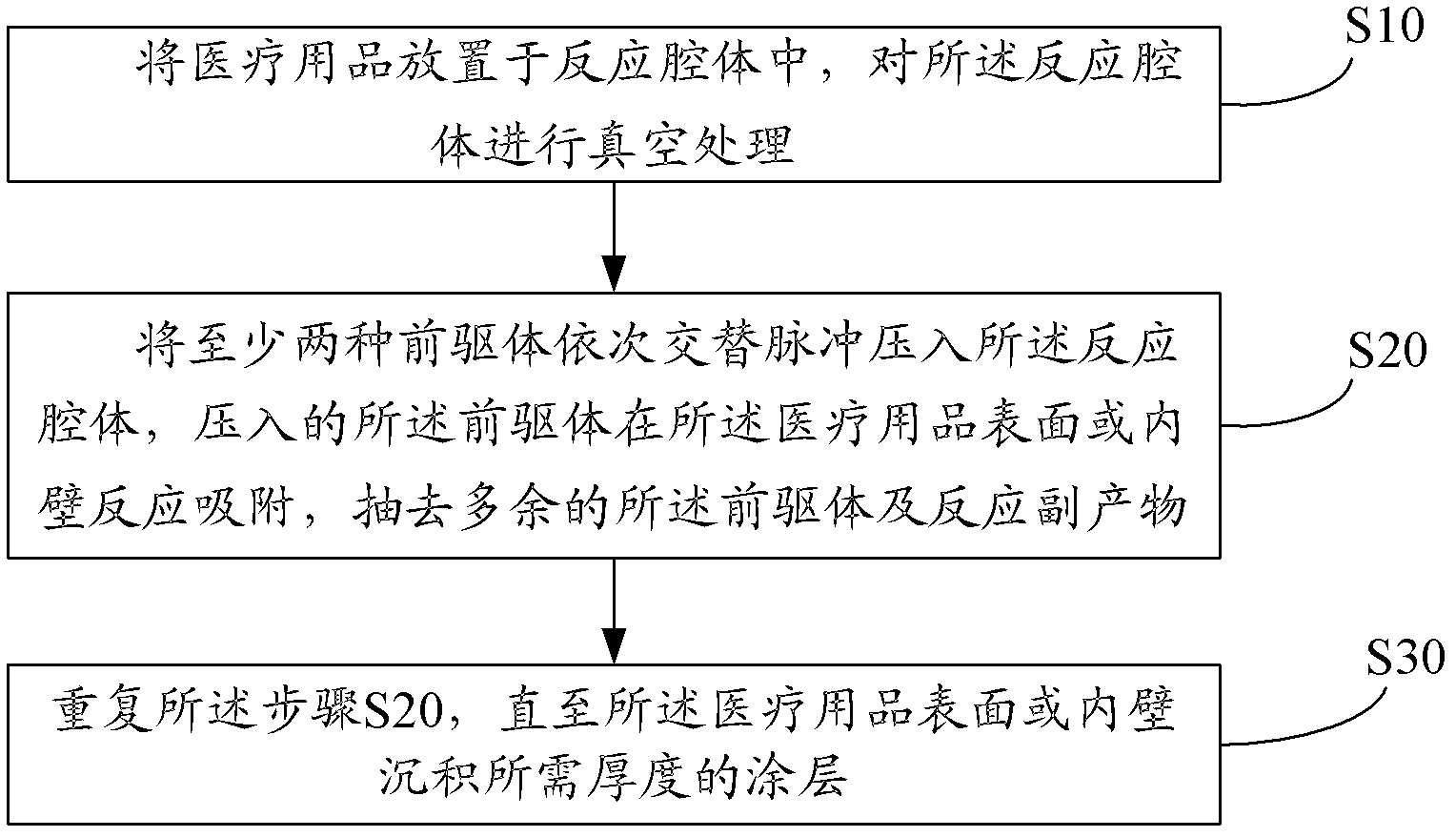

[0072] Such as figure 1 As shown, a method for preparing a coating of a medical product of the present invention includes: step S10: placing the medical product in a reaction chamber, and performing vacuum treatment on the reaction chamber; step S20: mixing at least two precursors Alternate pulses are pressed into the reaction chamber in turn, and the pressed precursor is reacted and adsorbed on the surface or inner wall of the medical product, and the excess precursor and reaction by-products are removed; step S30: repeat the step S20 , until a coating of required thickness is deposited on the surface or inner wall of the medical product.

[0073] Further, after placing the medical supplies in the reaction chamber, the step S10 may further include: adjusting the temperature of the reaction chamber to 5°C-1000°C. In this way, the uniformity of concentration and temperature in the entire reaction chamber is ensured, and the deposition process is optimized.

[0074] Further, a...

Embodiment 1

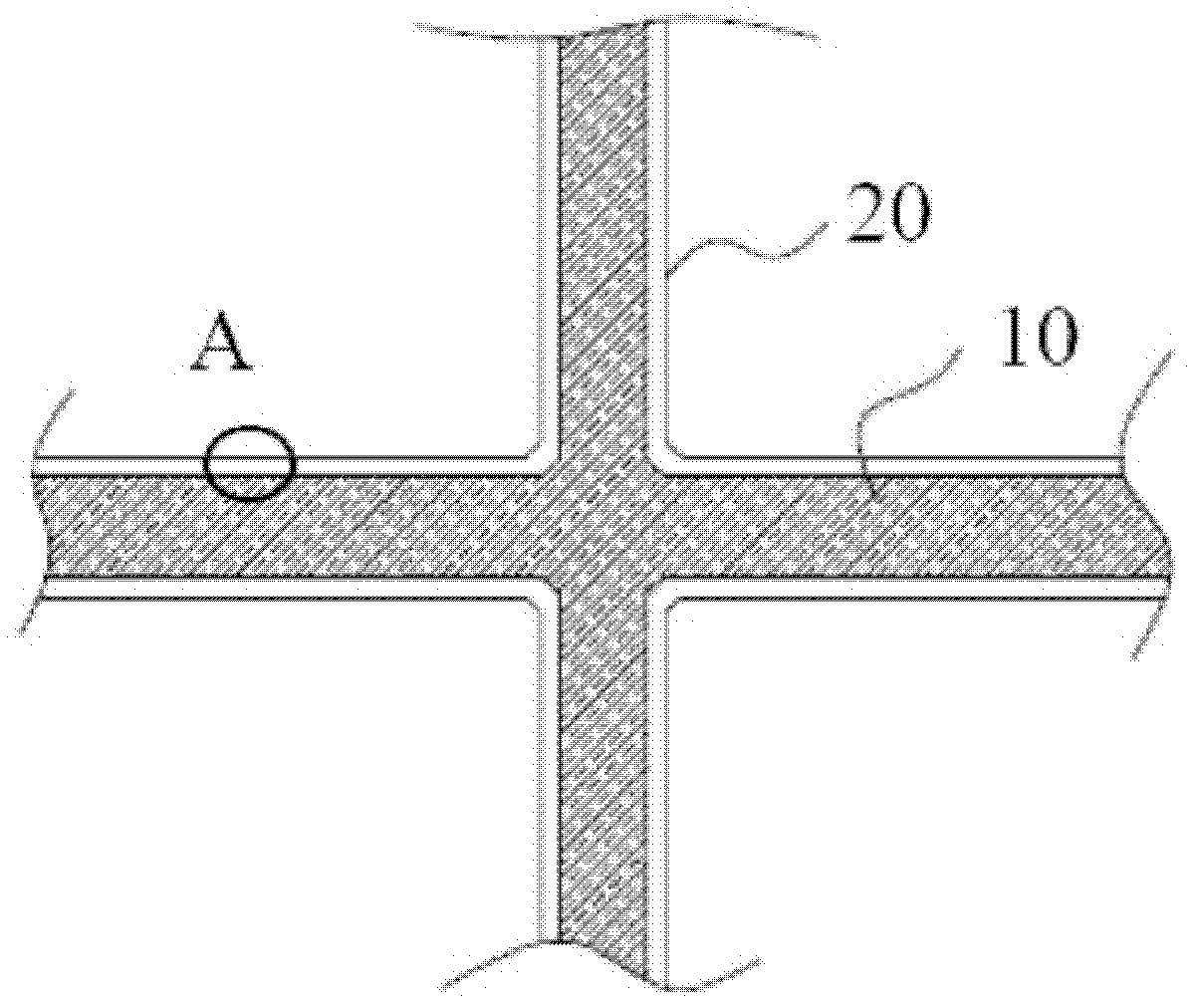

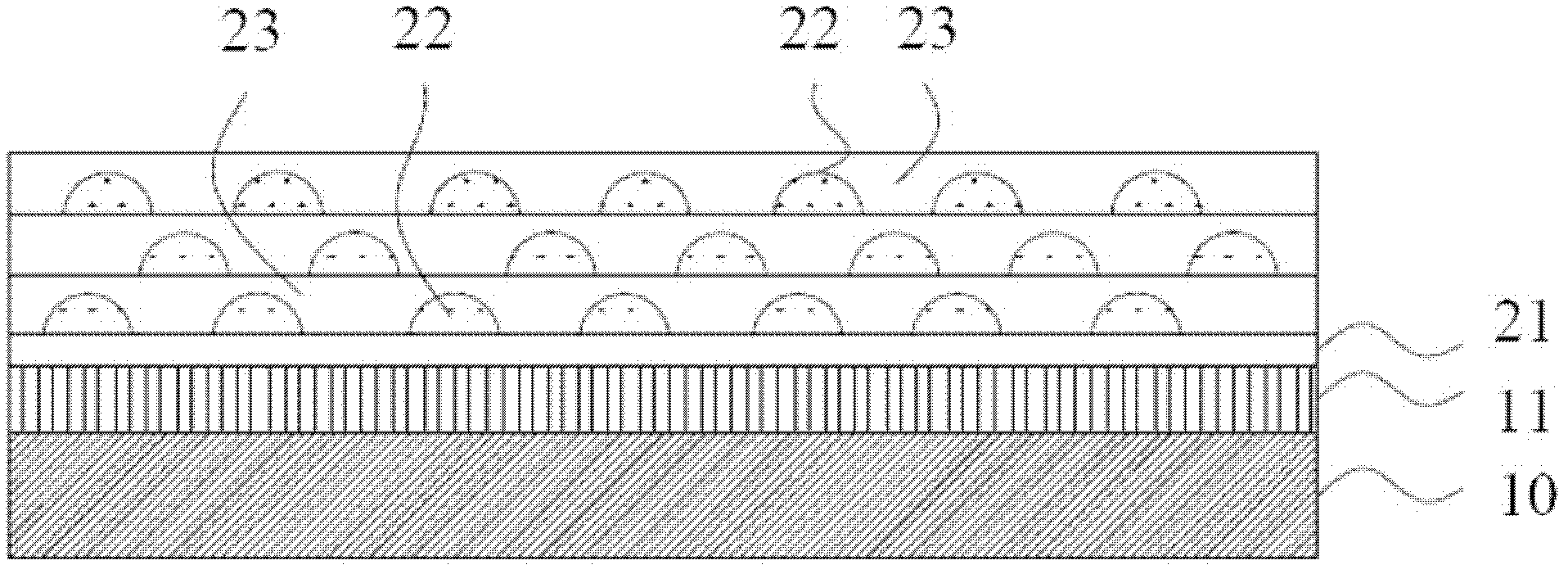

[0096] Such as figure 2 and image 3 As shown, the stainless steel bare drug slow-release stent 10 is coated with the active drug paclitaxel 11 and placed in the reaction chamber, and the vacuum degree of the reaction chamber is 9×10 -2 Torr, the reaction chamber temperature is 5°C.

[0097] Firstly, pulse the trimethylaluminum (TMA) precursor for 0.005 s, pump the air for 0.1 s; then pulse H 2 O precursor 0.2s, pumping for 100s; alternating pulses 150 times in sequence to obtain Al 2 o 3 The coating 21 has a thickness of about 15 nm.

[0098] Then, pulse tetrakis(ethylmethylamino)titanium (TEMAT) precursor for 0.05s, and pump for 100s; then pulse H 2 O precursor 0.2s, pumping for 100s; alternately pulsed 6 times in sequence to obtain TiO 2 The coating 22 has a thickness of about 0.5 nm. The TiO 2 The coating 22 is relatively thin, and is a discontinuous coating, which is evenly distributed in the shape of islands on the Al 2 o 3 The surface of the coating 21.

[0...

Embodiment 2

[0102] Such as Figure 4 As shown, the titanium dental implant 30 is placed in the reaction cavity, and the vacuum degree of the reaction cavity is 1×10 -4 Torr, the reaction chamber temperature is 350°C.

[0103] Pulsed TiCl 4 Precursor for 10s, pumping for 50s; then pulse NH 3 Plasma for 50 s, air pumping for 450 s; alternately pulsed 1000 times in turn to obtain a new type of medical product with a TiN coating 31 (its thickness is about 42 nm)—a new type of titanium bone implant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com