Heating control method of food processing machine

A food processor, heating control technology, applied in cooking utensils, household utensils, applications, etc., can solve the problems of unable to meet the multi-functional pulping requirements of food processors, single heating method, unstable, etc., to reduce the amount of steam generated , to ensure stability and reliability, to ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

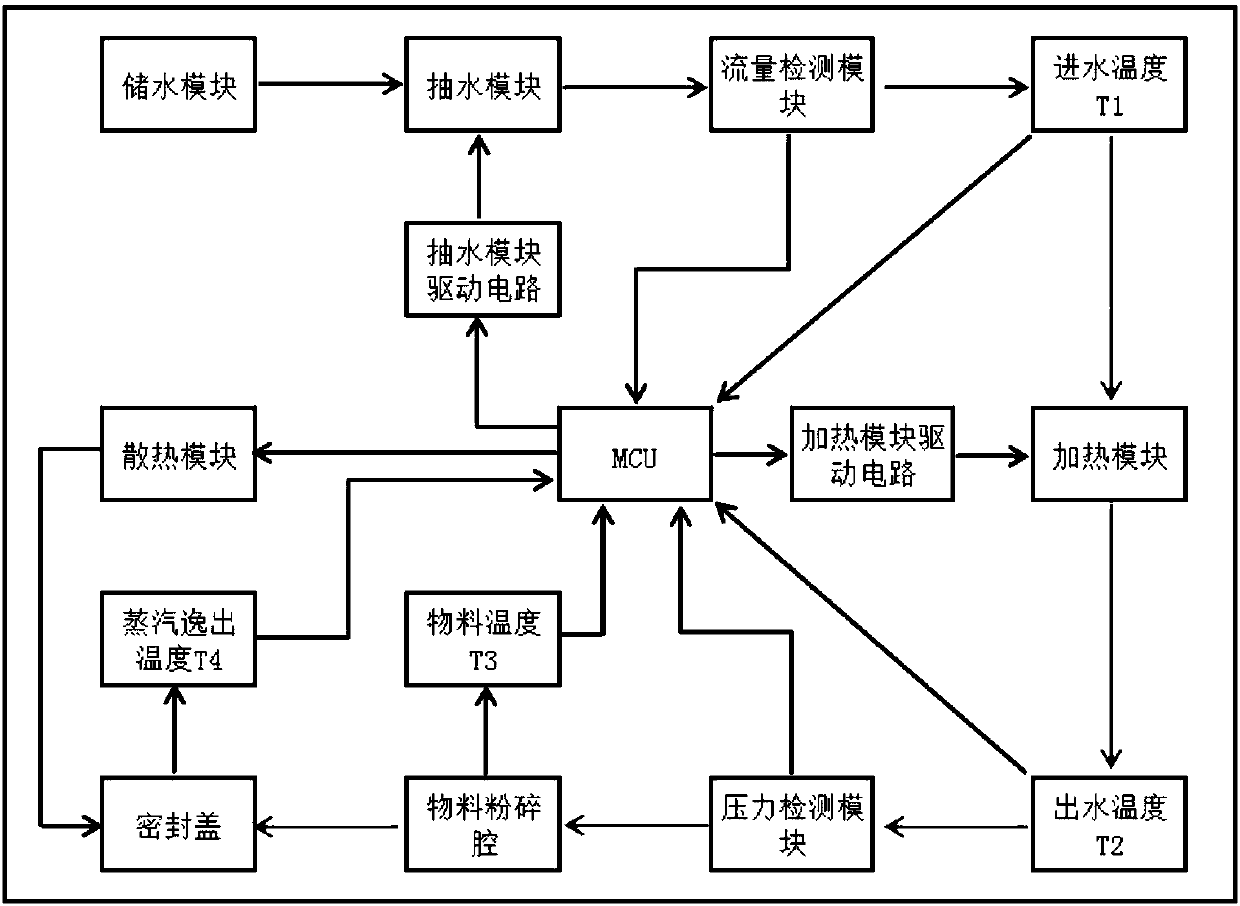

[0053]A heating control method for a food processing machine, the heating system of the food processing machine includes a steam generating device, the steam generating device includes a heating tube; the heating tube converts the water entering the steam generating device into water vapor, and the heating system passes the output steam heat the material, figure 1 As shown, the method may include S101:

[0054] S101. Control the water outlet state of the steam generator by controlling the water inlet speed and outlet water temperature of the steam generator, so as to realize multiple heating methods.

[0055] Optionally, the water outlet state includes: water, a water-steam mixture, and steam.

[0056] In the embodiment of the present invention, the heating system can set the water inlet speed and water outlet temperature. Different water inlet speeds determine the amount of water inlet and steam per unit time, and different outlet water temperatures determine whether the out...

Embodiment 2

[0079] The difference between this embodiment and the first embodiment is that another method for obtaining the outlet steam temperature when outputting the water-steam mixture or steam is provided.

[0080] Optionally, the method further includes: when outputting the water-steam mixture or steam, determining the outlet steam temperature according to different heating modes, and outputting the water-steam mixture or steam when the temperature of the water-steam mixture or steam reaches the determined outlet temperature;

[0081] Among them, the heating mode includes: rapid heating, normal heating, boiling heating and heat preservation heating.

[0082] Optionally, determining the outlet steam temperature according to different heating modes includes:

[0083] When in the rapid heating mode, the outlet steam temperature is set at a temperature higher than the boiling point and meets the first temperature range;

[0084] When in the normal heating mode, the outlet steam tempera...

Embodiment 3

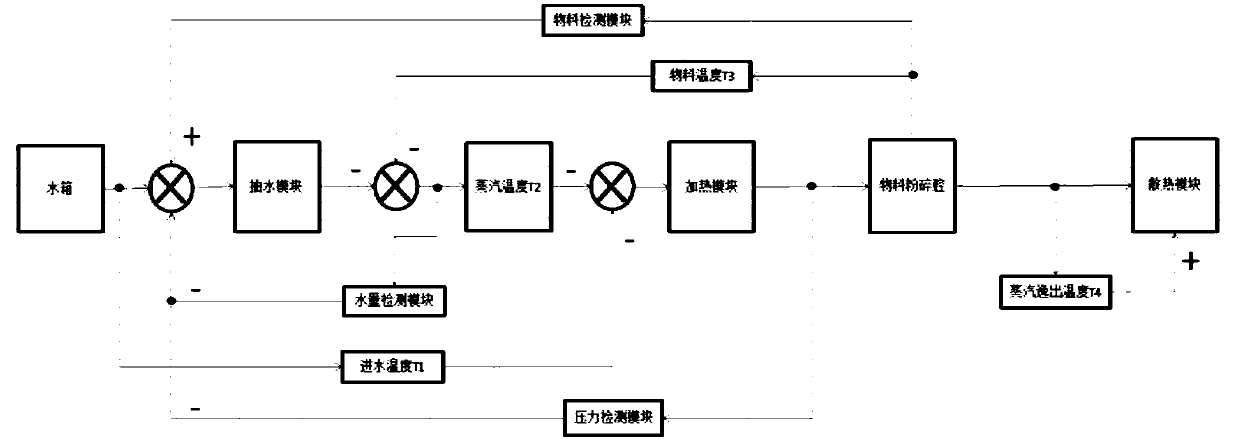

[0091] like image 3 As shown, the difference between this embodiment and the first embodiment is that a closed-loop control is implemented on the water inlet speed, outlet water temperature and outlet steam temperature.

[0092] Optionally, the method may further include: detecting the outlet water temperature and the outlet steam temperature in real time, and performing closed-loop control on the water outlet speed and the heating power of the heating pipe according to the real-time detected outlet water temperature and outlet steam temperature.

[0093] Optionally, the closed-loop control of the water outlet speed and the heating power of the heating pipe through the real-time detected outlet water temperature and outlet steam temperature may include:

[0094] When it is detected that the temperature value of the outlet water temperature is higher than the corresponding preset temperature and reaches the preset first threshold, judge the heating power gear Level of the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com