Cleaning device and cleaning method of glass substrate

A technology for glass substrates and cleaning devices, applied in liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning effect and high cost, and achieve good cleaning effect, low cost, and low cost higher effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

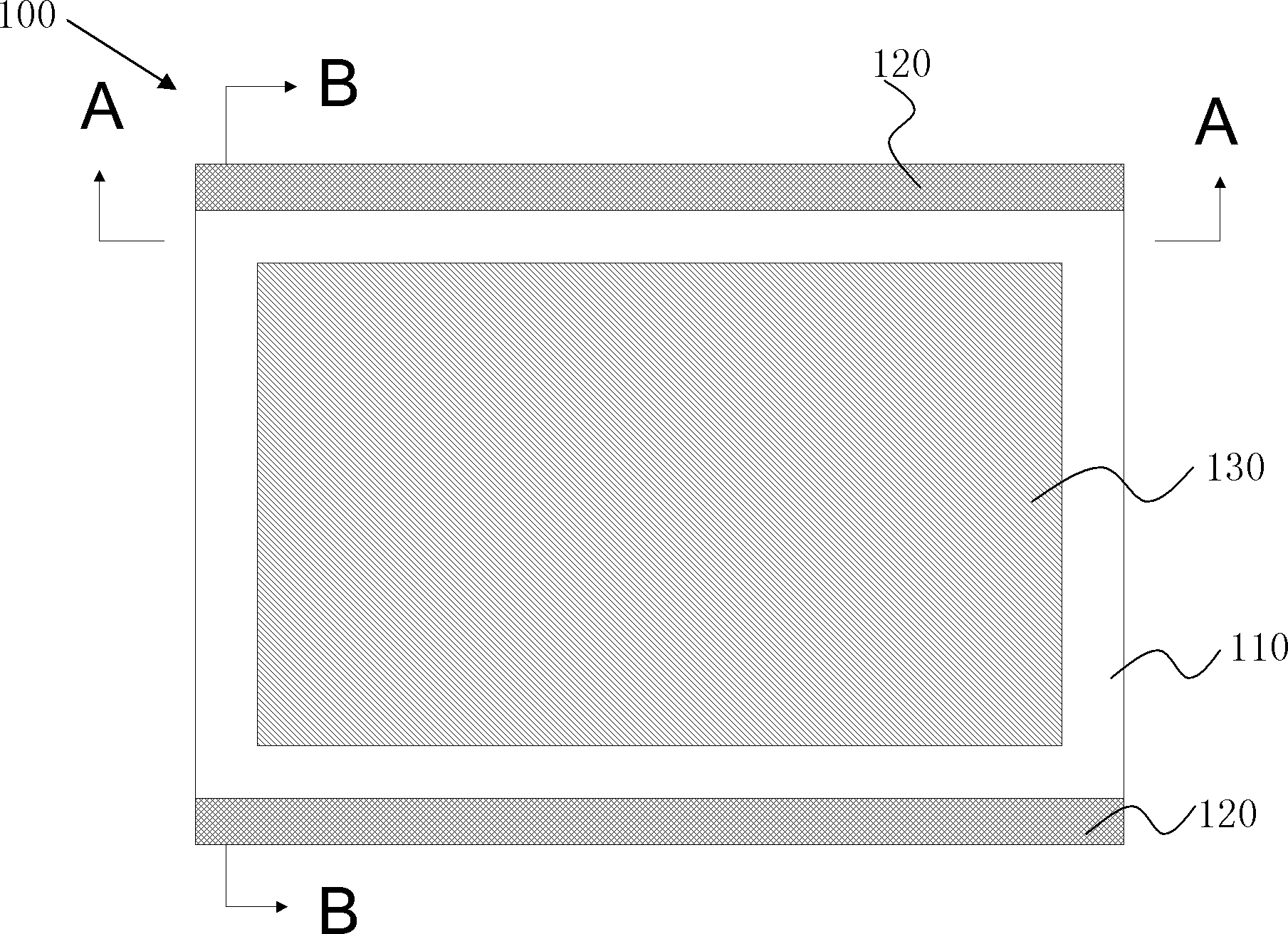

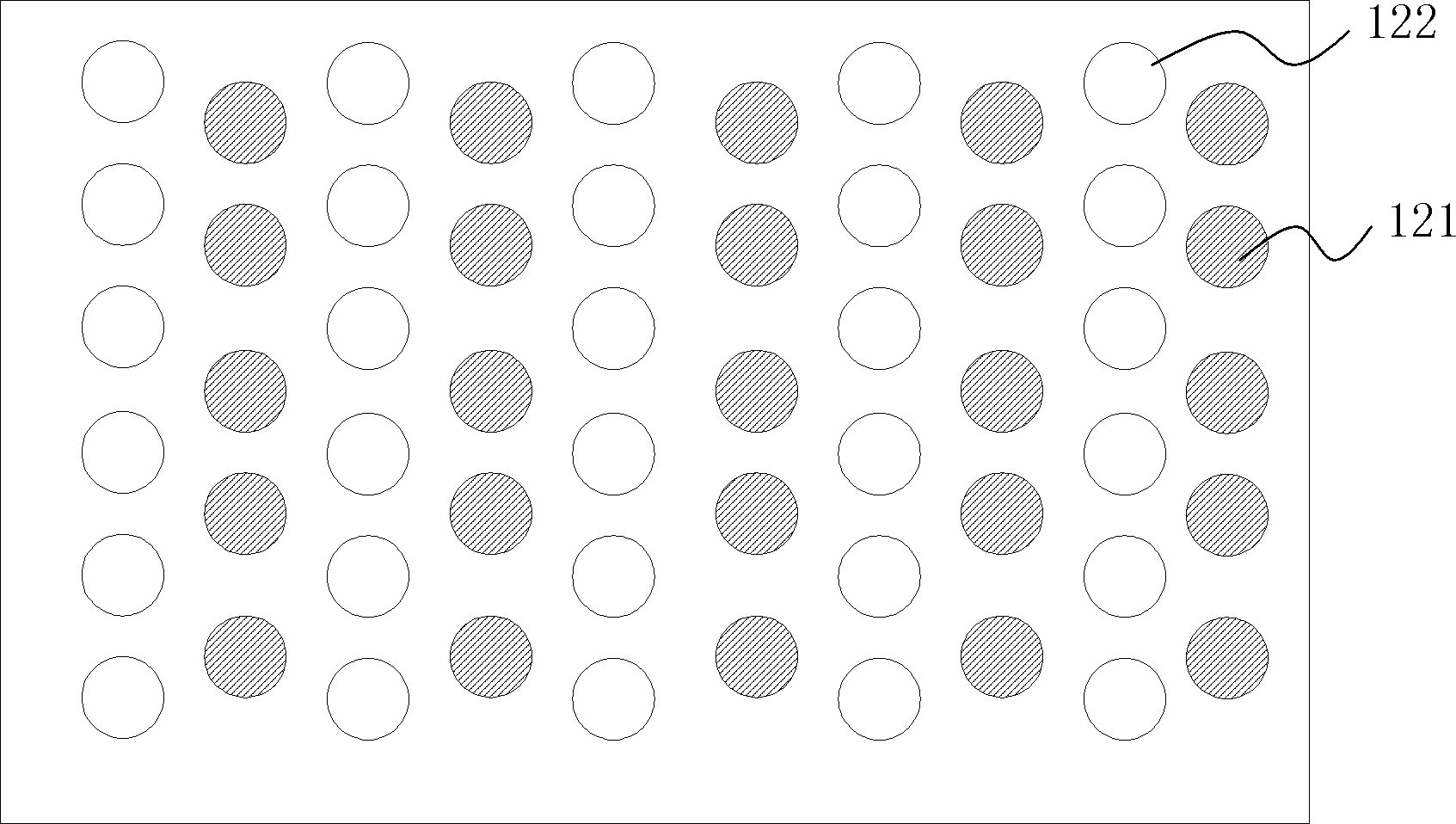

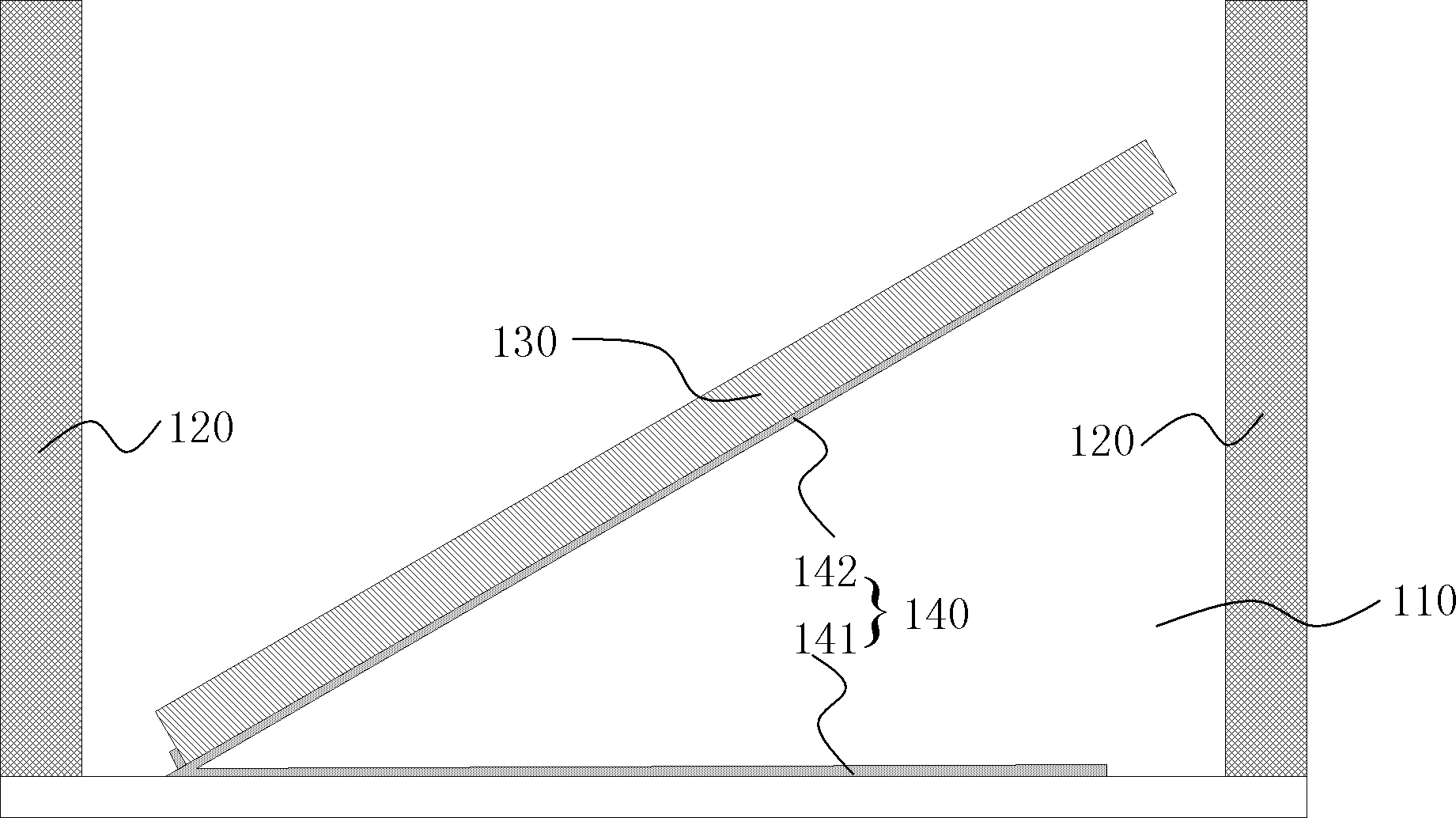

[0031] figure 1 It is a structural schematic diagram of a preferred embodiment of the glass substrate cleaning device of the present invention, figure 2 for figure 1 Schematic diagram of the structure of the A-A section, image 3 for figure 1 Schematic diagram of the structure of the B-B section. The present invention relates to a glass substrate cleaning device 100, the glass substrate cleaning device 100 includes a cleaning tank 110 and a first frequency generator 121 and a second frequency generator 122 arranged on both sides of the cleaning tank 110, wherein the first frequency The generator 121 is used to send out ultrasonic waves with a first frequency, and the second frequency generator 122 is used to send out ultrasonic waves with a second frequency.

[0032] When cleaning, the substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com