Laser cleaning device and method

A laser cleaning and cleaning technology, which is applied in the field of laser cleaning, can solve the problems of damage to the cleaning device, difficult discharge of dust and particles, and adjustment of the focus position of the laser beam for free movement of the pipeline, etc., to achieve the effect of efficient absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

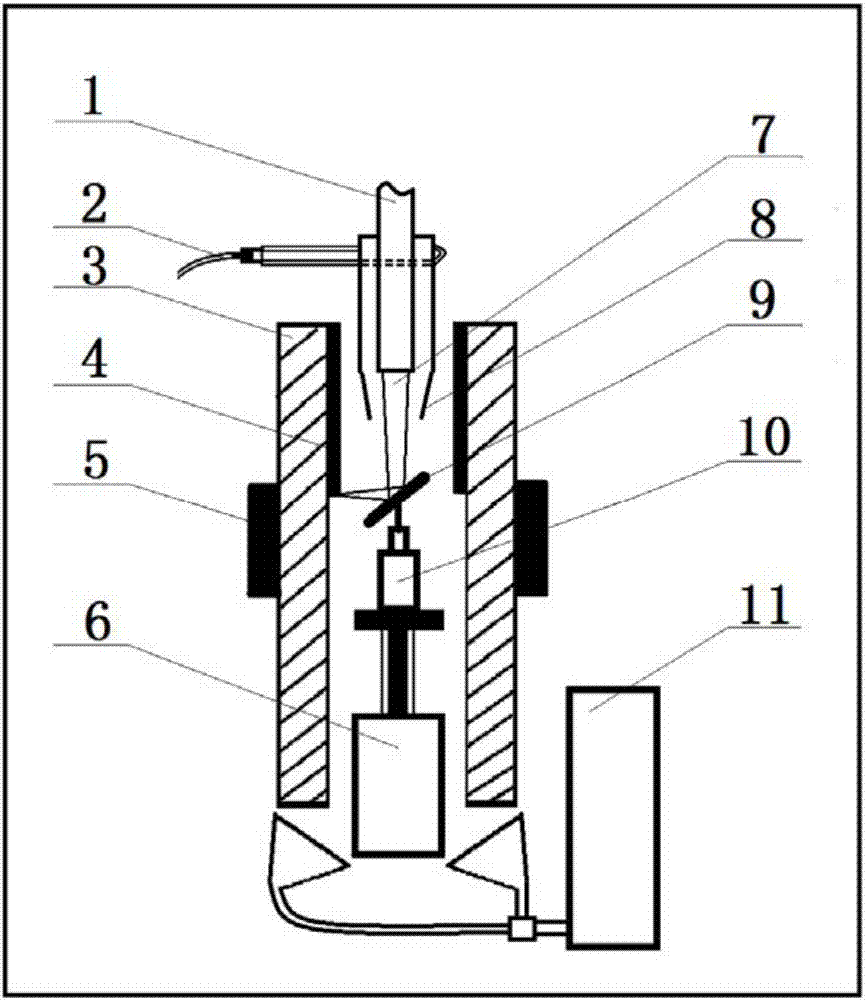

[0032] figure 1 It is a structural diagram of a laser cleaning device in Embodiment 1 of the present invention. This embodiment is applicable to situations where laser cleaning is required on the inner wall of a pipeline. refer to figure 1 , The laser cleaning device provided in this embodiment includes: a laser source 1, a gas nozzle 8, a gas delivery module 2, a mirror 9, a motor 10, an electric slide 6 and a smoke absorber 11;

[0033] The laser source 1 is used to emit a laser beam 7 toward the inner cavity of the pipeline 3 to be cleaned; the reflector 9 is used to reflect the laser beam 7 to the inner wall layer 4 of the pipeline 3 to be cleaned; the The gas delivery module 2 communicates with the gas nozzle 8 for delivering compressed gas to the inner cavity of the pipeline 3 to be cleaned through the gas nozzle 8;

[0034] The laser source 1, the gas nozzle 8 and the motor 10 are coaxially arranged, and the coaxial line coincides with the axis of the pipeline to be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com