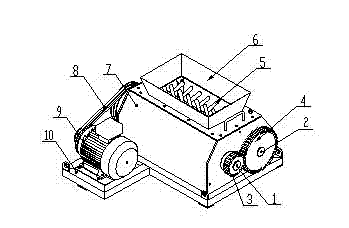

Double-shaft spike-tooth beater

A technology of breaking machine and shaft nails, which is applied in the fields of application, food processing, food science, etc., can solve the problems of fine crushing particle size and high cost, and achieve the effects of low cost, convenient operation and easy production and manufacture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

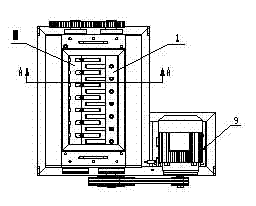

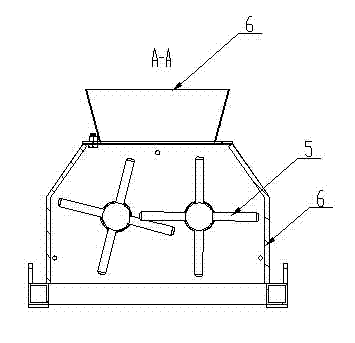

[0013] Install and set casing 7, motor 9, driving shaft 1, driven shaft 2 on frame 10, driving shaft 1 and driven shaft 2 are parallel, and place in casing 7, two parallel main and driven shafts Evenly distributed nail teeth 5 are respectively arranged on the top, and a pair of intermeshed driving and driven gears are arranged at the same end of the driving and driven shafts. The driving and driven gears are respectively fixed with the driving and driven shafts. The number of teeth of the driving gear is Half of the number of teeth of the moving gear, so that the two shafts rotate in reverse, and the differential speed is broken up, thus fully ensuring the efficiency of breaking up. The nail teeth on the two shafts are staggered with each other, and a certain distance is maintained to ensure that the skin dregs are broken up to achieve a relatively uniform particle size requirement. Belt pulleys are respectively arranged on the motor shaft and the driving shaft, and the belt 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com