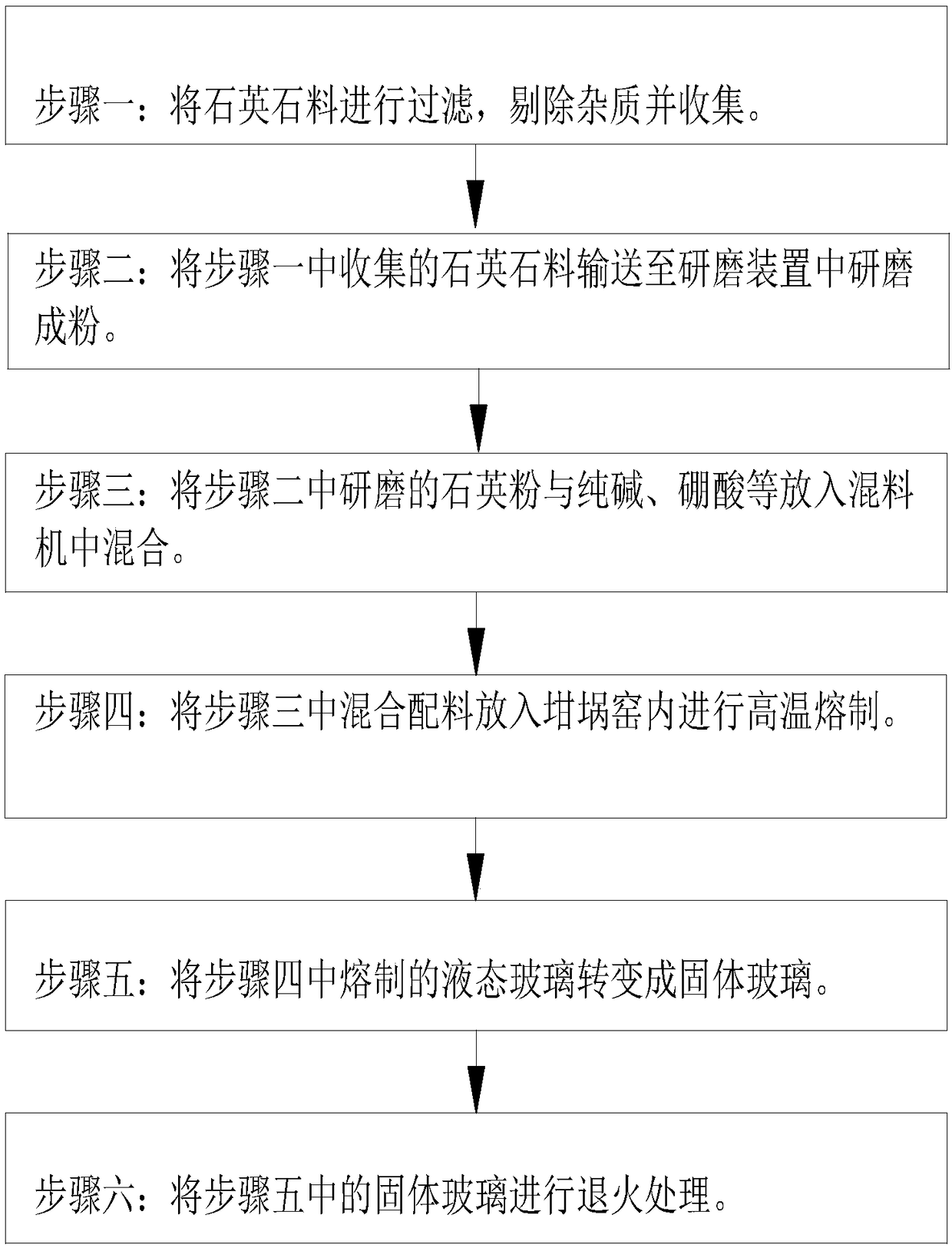

Glass production method

A production method and glass technology, applied in the direction of cocoa, grain processing, food science, etc., can solve the problems of not being able to quickly and adequately, limited, and unable to effectively target the quartz stone, so as to improve the grinding efficiency and grinding quality, increase the broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

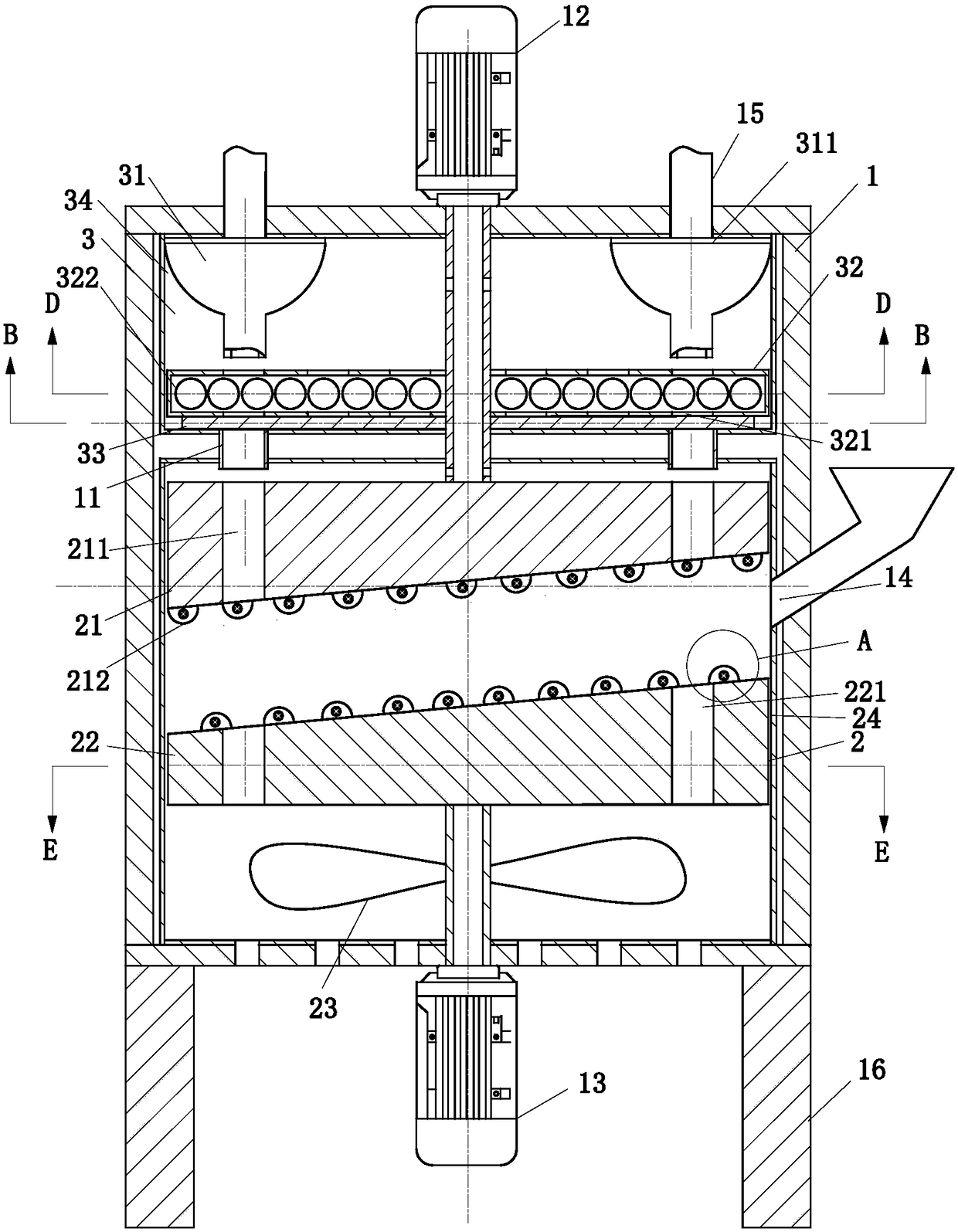

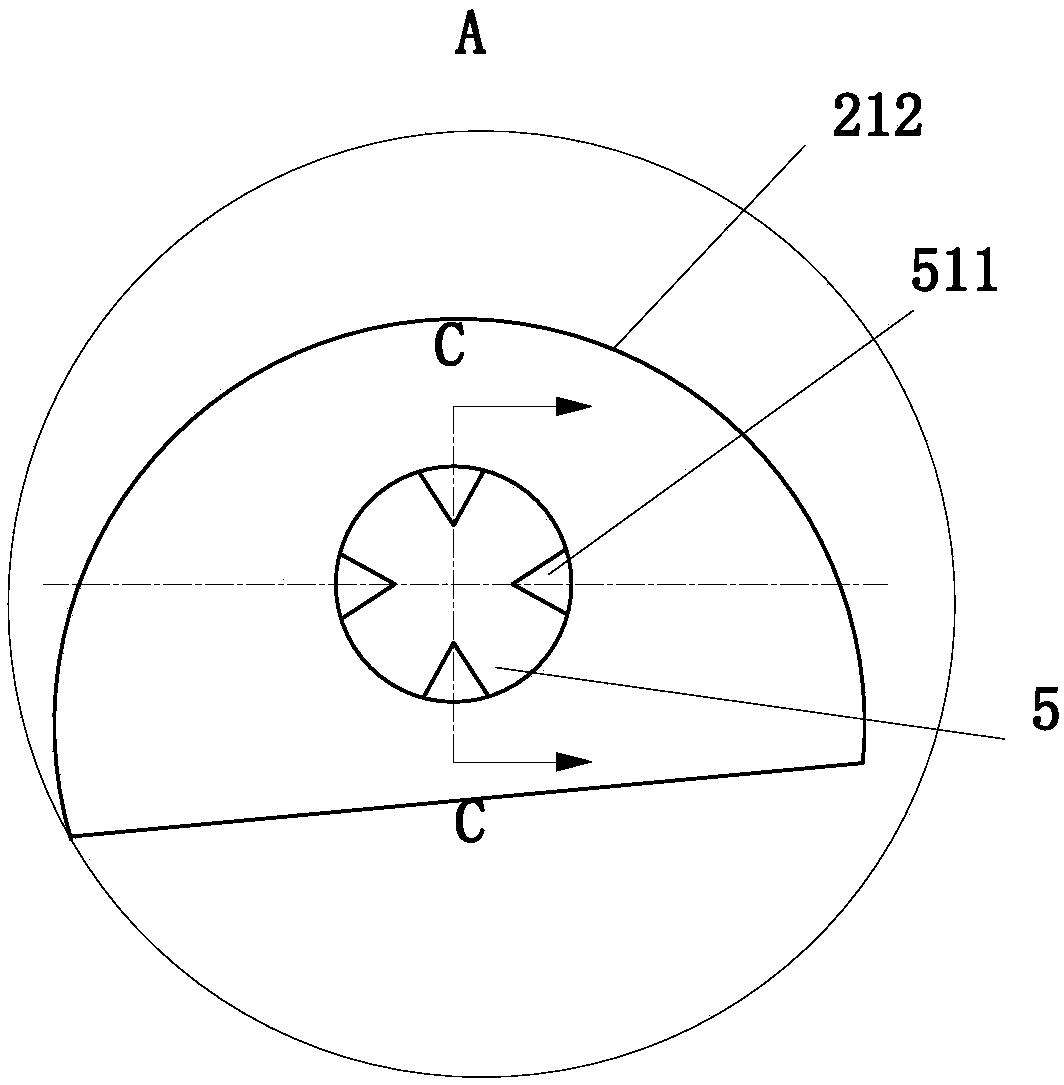

[0044] As an embodiment of the present invention, the sections of the No. 1 grinding column 21 and the No. 2 grinding column 22 are trapezoidal; the sections of the No. 1 grinding column 21 and the No. 2 grinding column 22 are equipped with semi-cylindrical grinding blocks 212, a cylindrical hole 5 is provided in the semi-cylindrical grinding block 212, and the No. 1 grinding column 21 matches the semi-cylindrical grinding block 212 in the No. 2 grinding column 22; the No. 1 grinding column 21 and the No. 2 grinding column 22 The opposite power is obtained from the first motor 12 and the second motor 13 respectively. Under the mutual cooperation of the No. 1 grinding column 21 and the No. 2 grinding column 22, the shaking of the quartz stone up and down produces a large impact on the quartz stone, making the The grinding is faster, and at the same time, the through hole on the hollow shaft prevents the blockage of the quartz stone, thereby improving the grinding efficiency; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com