Vertical roller grinding machine for super-fine powder

A vertical roller mill and ultra-fine powder technology, applied in grain processing and other directions, can solve the problems affecting the quality and stability of grinding and milling, improve and stabilize the quality of grinding and milling, increase the stability of milling, and improve the quality of grinding and milling. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

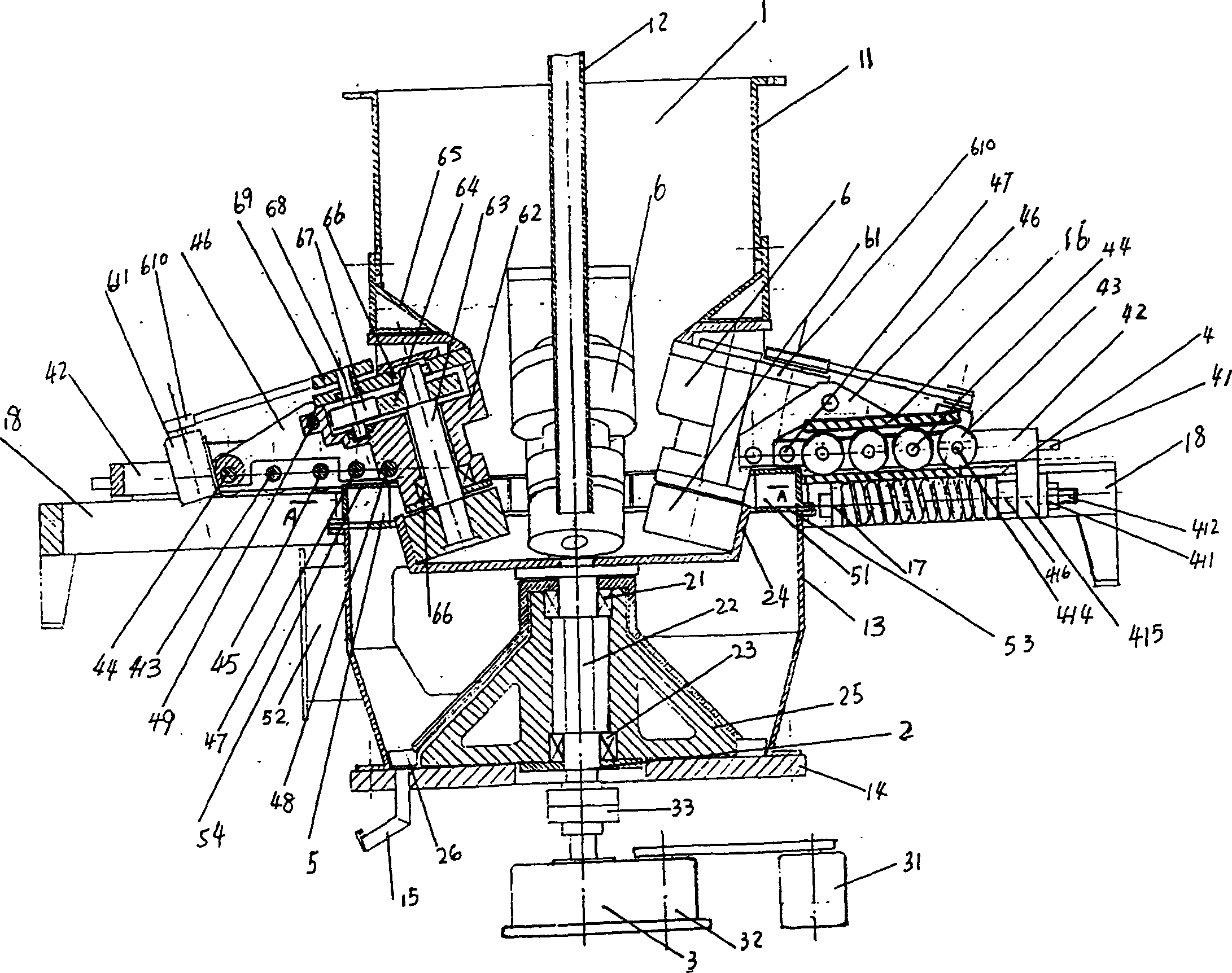

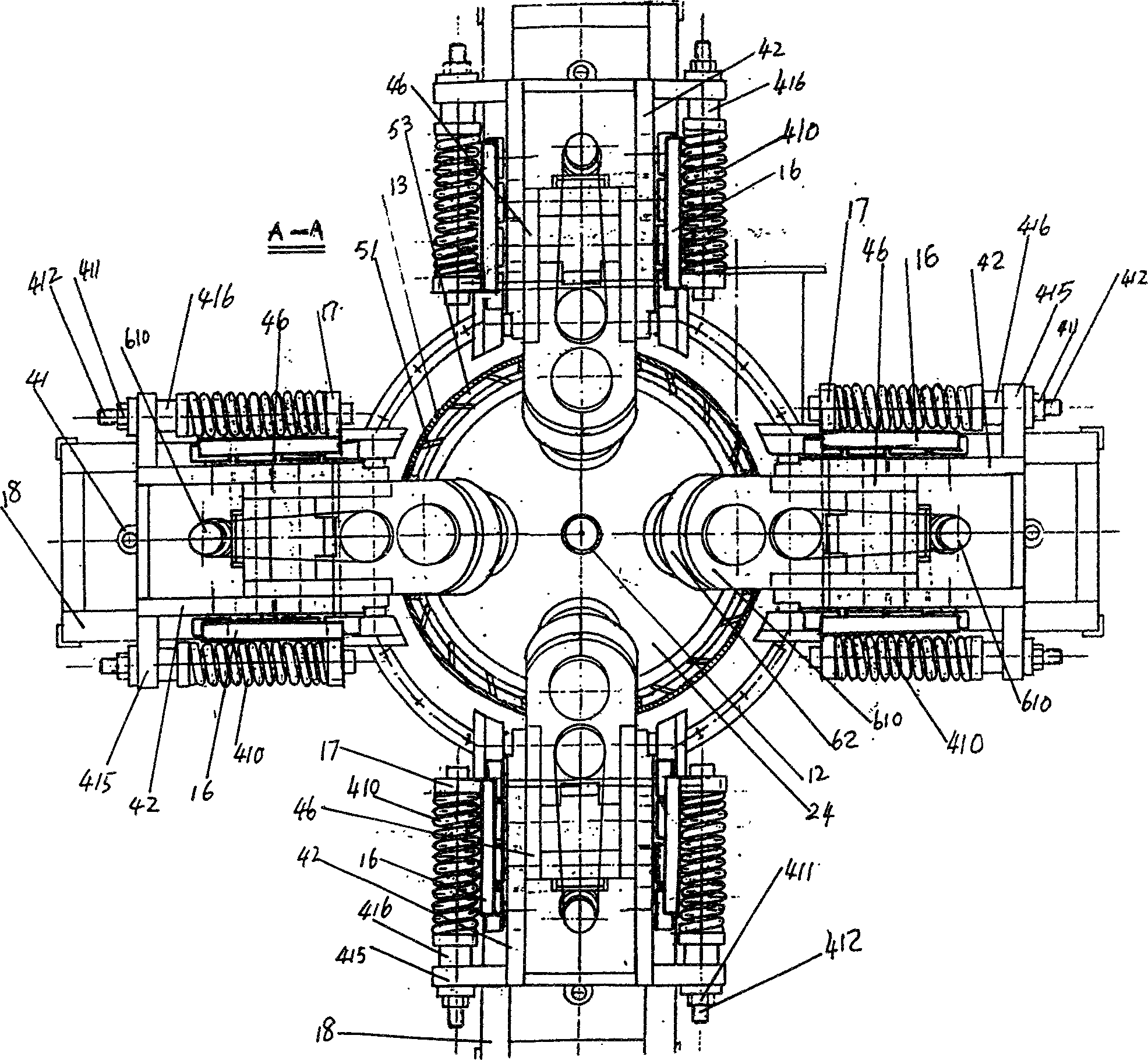

[0038] like figure 1 , 2 , 3, the present invention comprises a body 1, a large grinding disc 24 arranged in the body 1, a power transmission device for driving the large grinding disc 24 to rotate, an air intake system communicated with the large grinding disc 24, and the feeding of materials that are arranged in the middle of the body Tube 12.

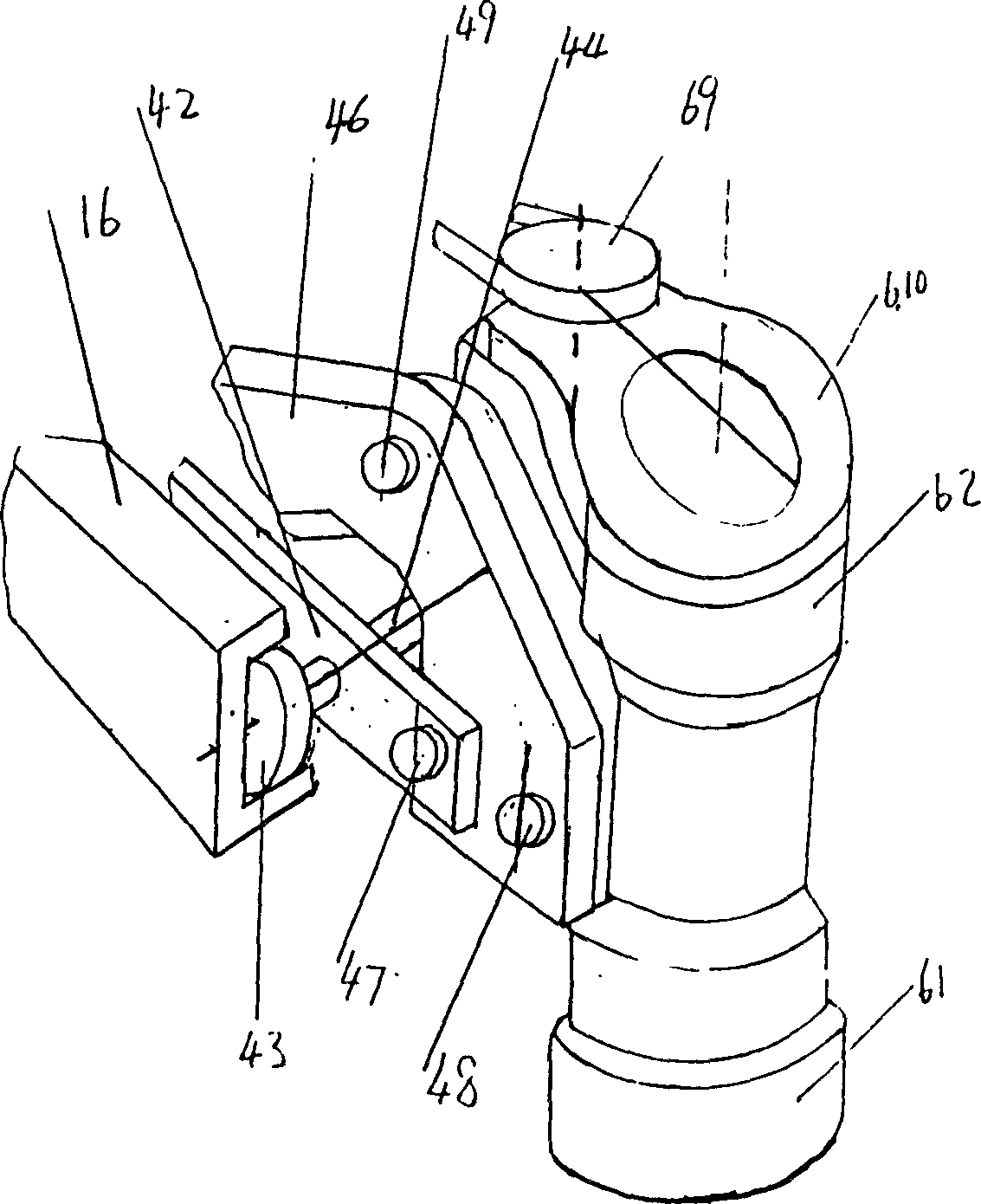

[0039] The large grinding table 24 is driven by the transmission system 3 composed of the motor 31 and the reducer 32 at its lower part through the central vertical spindle 22, and the grinding head 6 matched with the large grinding table 24 is arranged on the large grinding table 24, and the grinding head 6 is supported on the moving trolley 4, the grinding head 6 is under the action of the elastic pressure device to press the grinding roller 61 of the grinding head 6 to the edge of the large grinding disc 24, and the grinding head motor for driving the grinding roller 61 of the grinding head 6 to rotate is installed on the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com