Rotary protecting hood of a pneumatic grinder

a protection hood and grinder technology, which is applied in the direction of grinding machines, portable grinding machines, metal-working equipment, etc., can solve the problems of inconvenience to operators, increased operation difficulty, and inability to adjust the position of the protection hood, so as to improve the convenience of operators and enhance the grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical contents of the present invention will now be described in more detail hereinafter with reference to the accompanying drawings that show various embodiments of the invention.

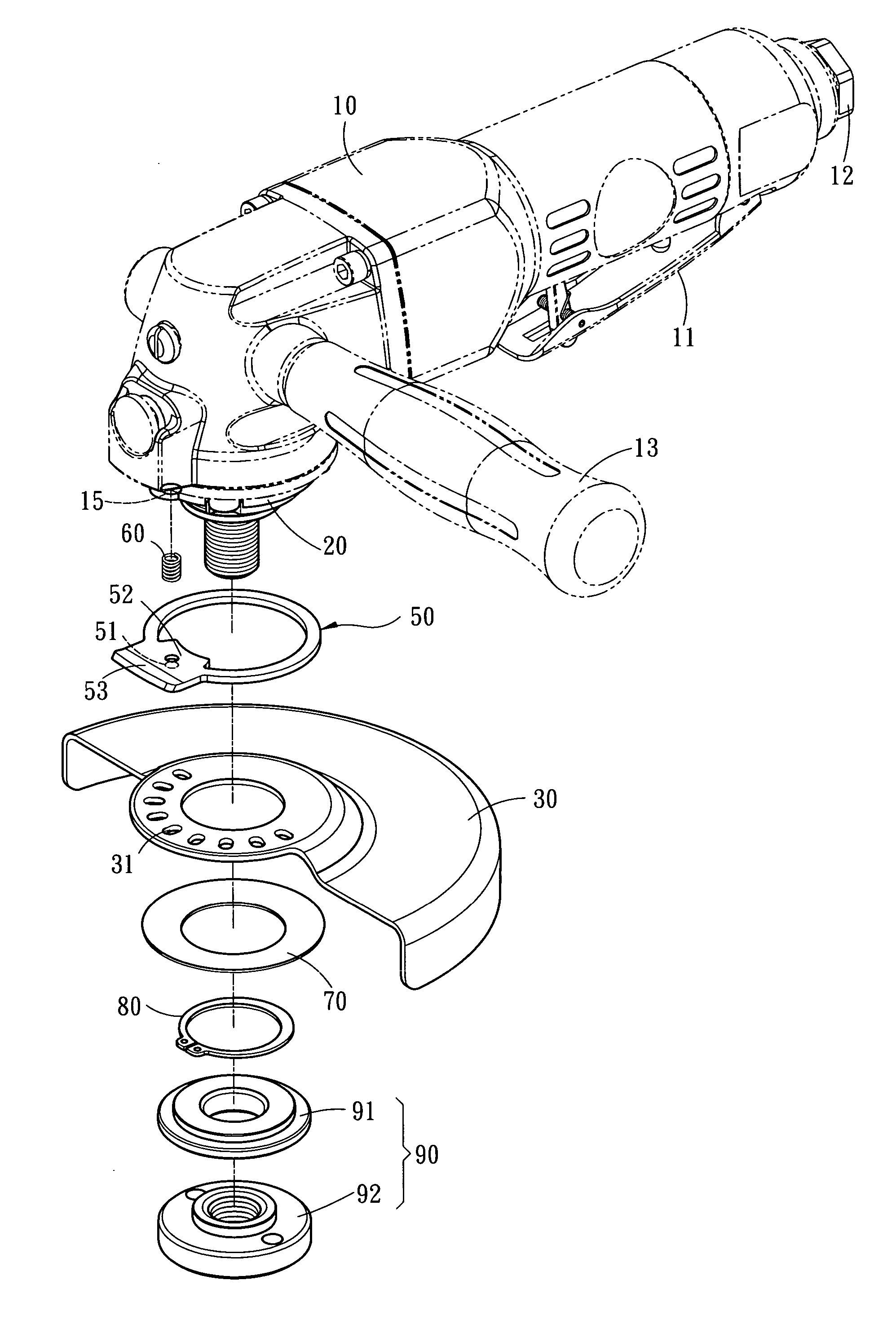

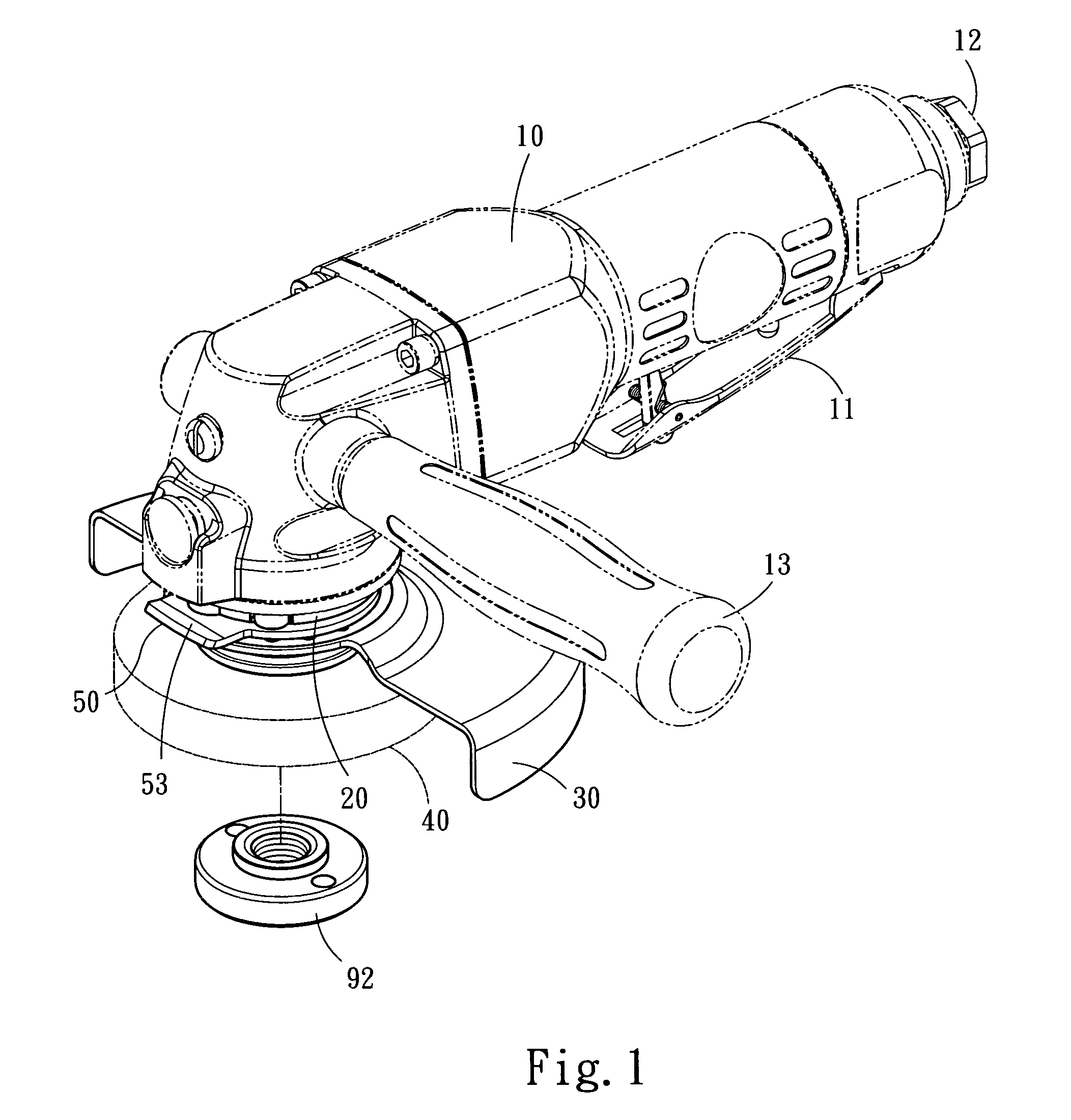

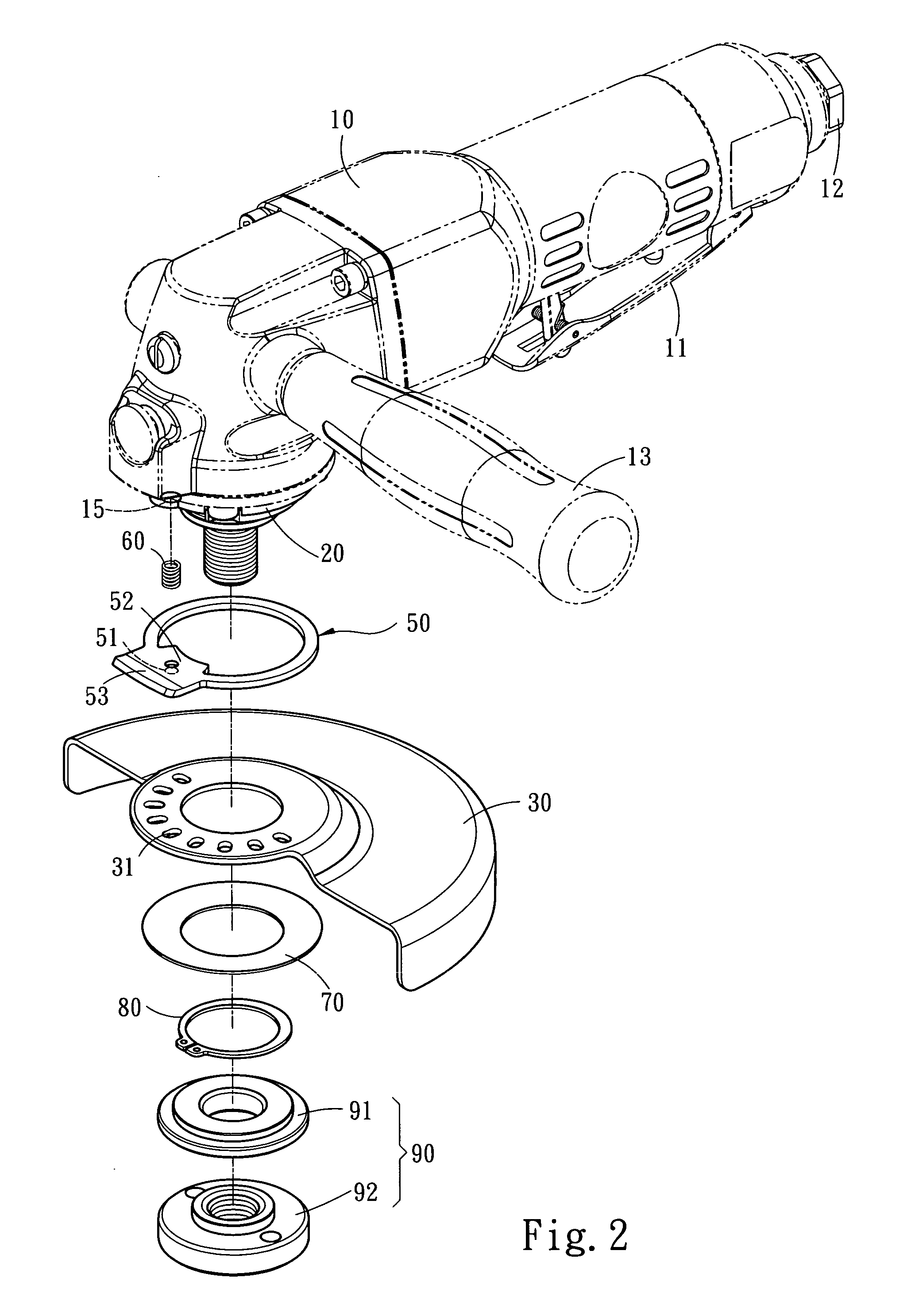

[0012] Referring to FIGS. 1 and 2 for the perspective view and the exploded view of the present invention, the invention includes a body 10, and the body 10 includes a connecting end 20 thereon, and the connecting end 20 includes a grinder wheel 40 and a clamping member 90 for fixing the grinder wheel 40, and the clamping member 90 comprises a supporting base 91 and a locking member 92. The connecting end 20 includes a protecting hood 30 for sheltering the grinder wheel 40, a latching member 70 for pressing the protecting hood 30 such that the protecting hood 30 will not be loosened, and a supporting member 80 for supporting the latching member 70. The body 10 includes an accessory handle 13 disposed at a lateral side for providing another holding position of the body 10, and the rear end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com