Woven Shutter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010]To make it easier for our examiner to understand the technical characteristics, objective and performance of the invention, we use a preferred embodiment together with the attached drawings for the detailed description of the invention.

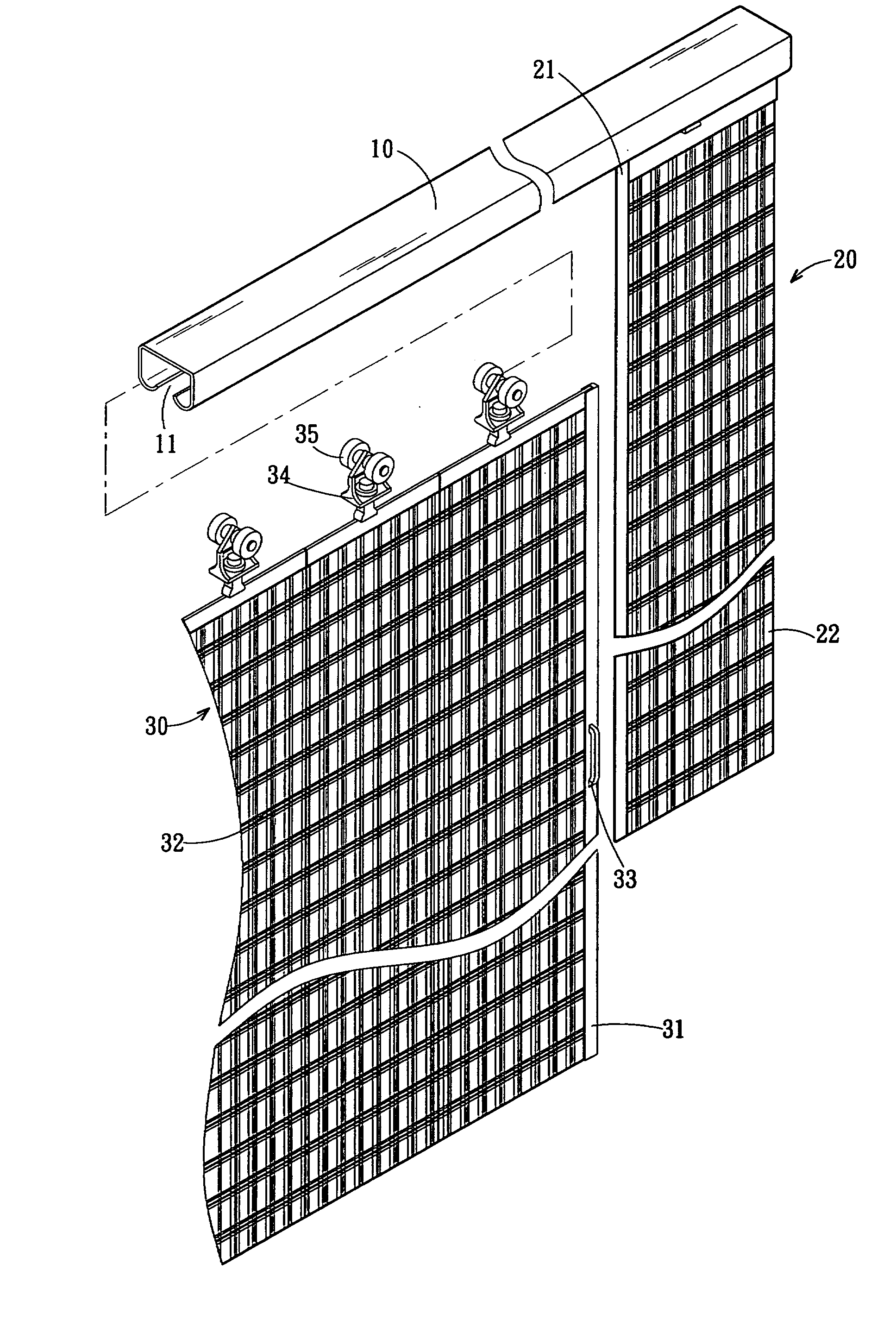

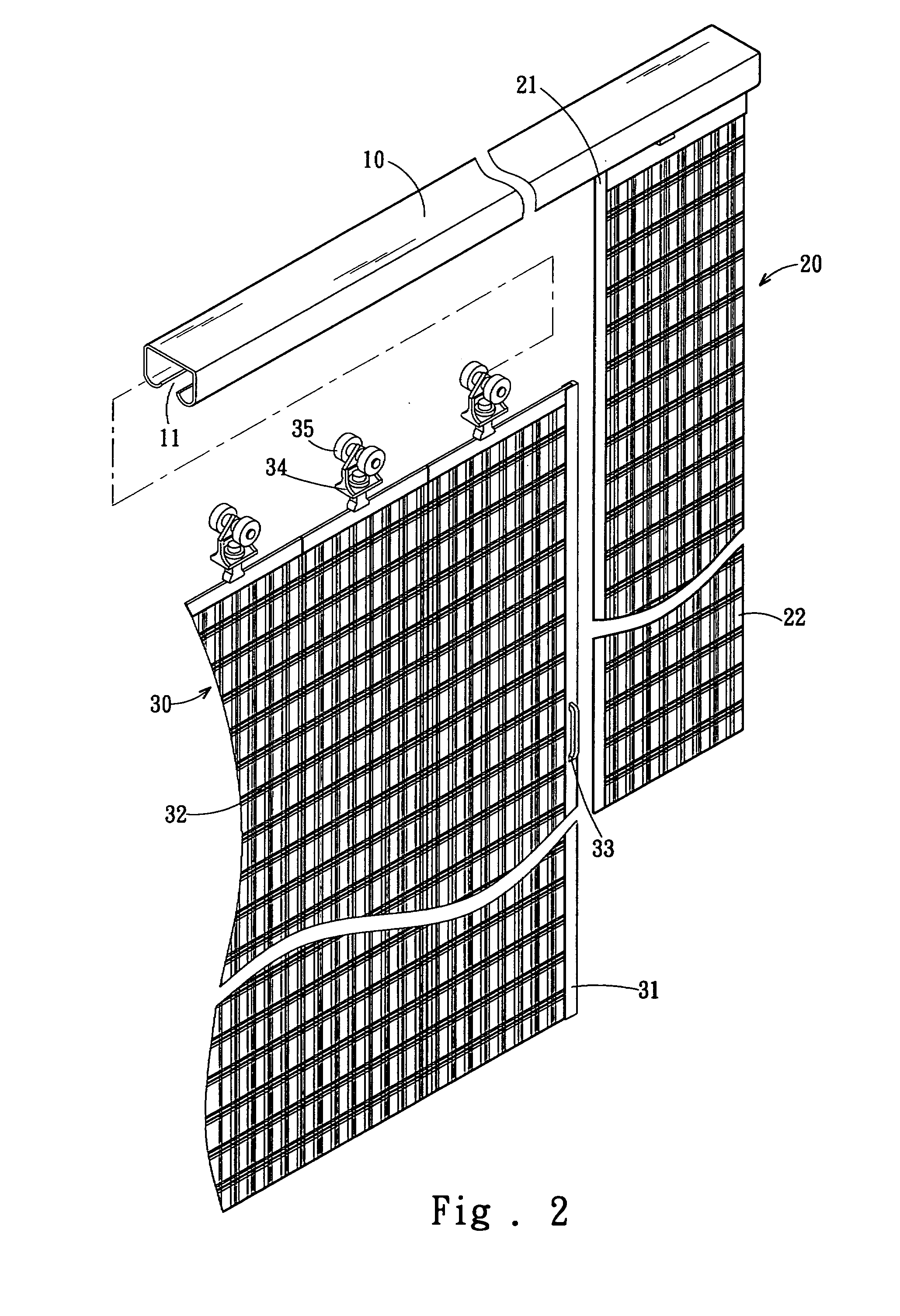

[0011]Referring FIG. 2, a woven shutter comprises the following elements:

[0012]A metal upper rail 10 is a rectangular hollow body and has an opening 11 disposed under the upper rail 10, and the width of the opening 11 is smaller than the internal width of the upper rail 10. A fixed vertical plastic first blind 20 has its top fixed to a side of the bottom of the upper rail 10, and the external side of the first blind 20 can be fixed onto a wall surface (not shown in the figure), and the internal side of the first blind 20 has a vertical first edge bar 21, and the first blind 20 is made of a sheet body 22, and the sheet body 22 and transversally woven materials form a rectangular surface with woven lines as shown in FIG. 3.

[0013]A movable and fold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com