Method and equipment for metal piece vibration grinding polishing and burring

A metal workpiece, deburring technology, applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as low efficiency, poor economic benefits, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

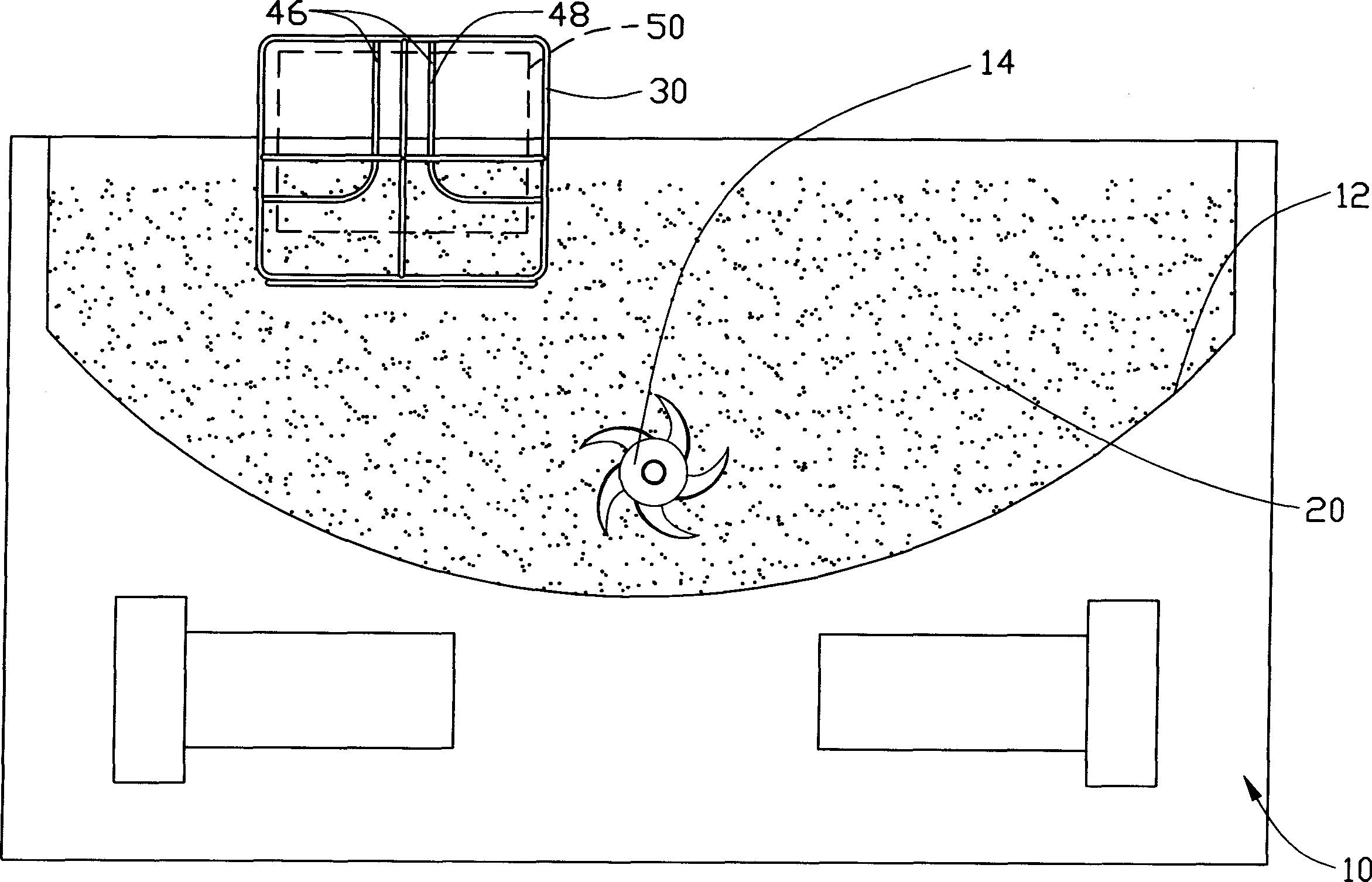

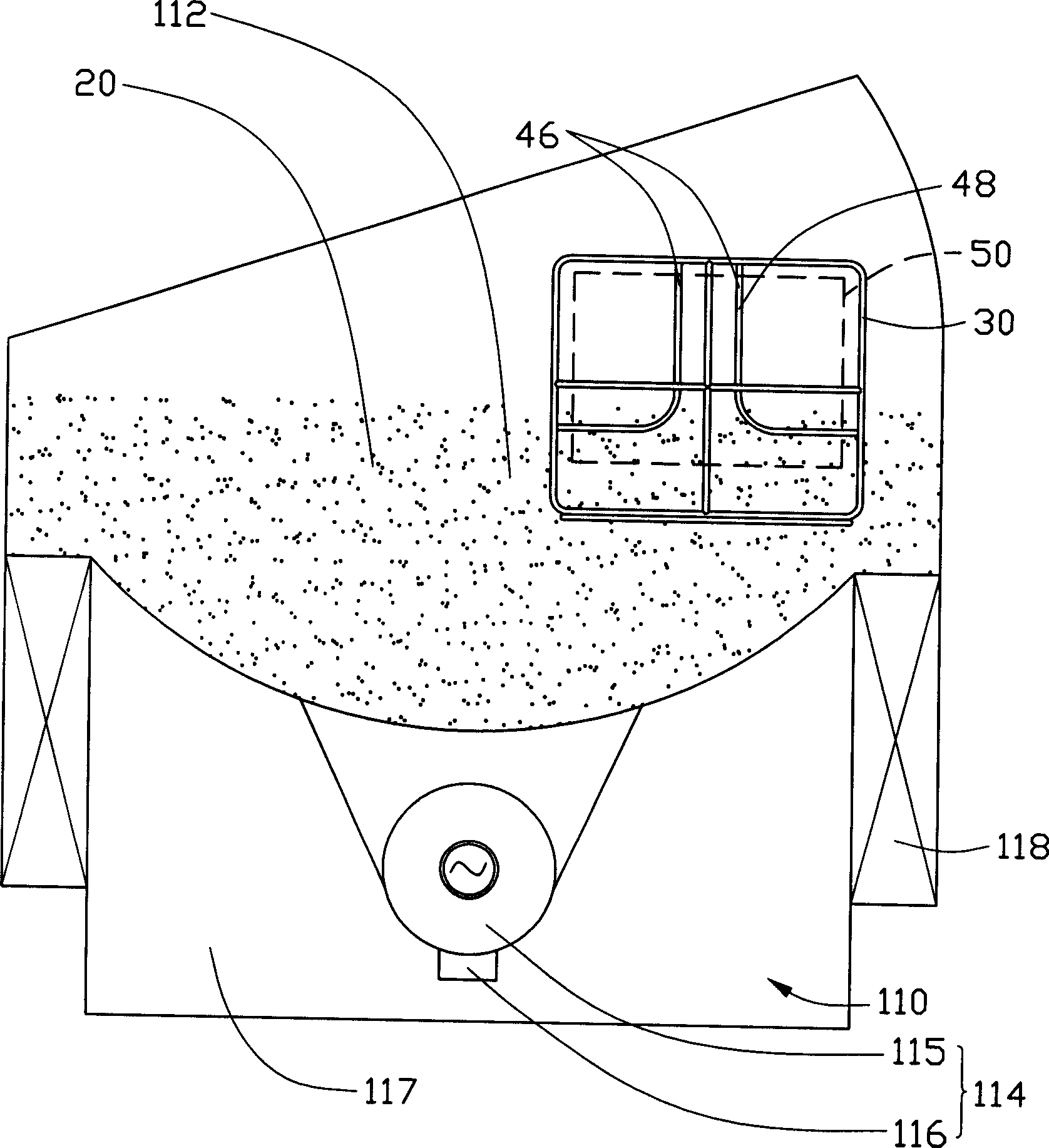

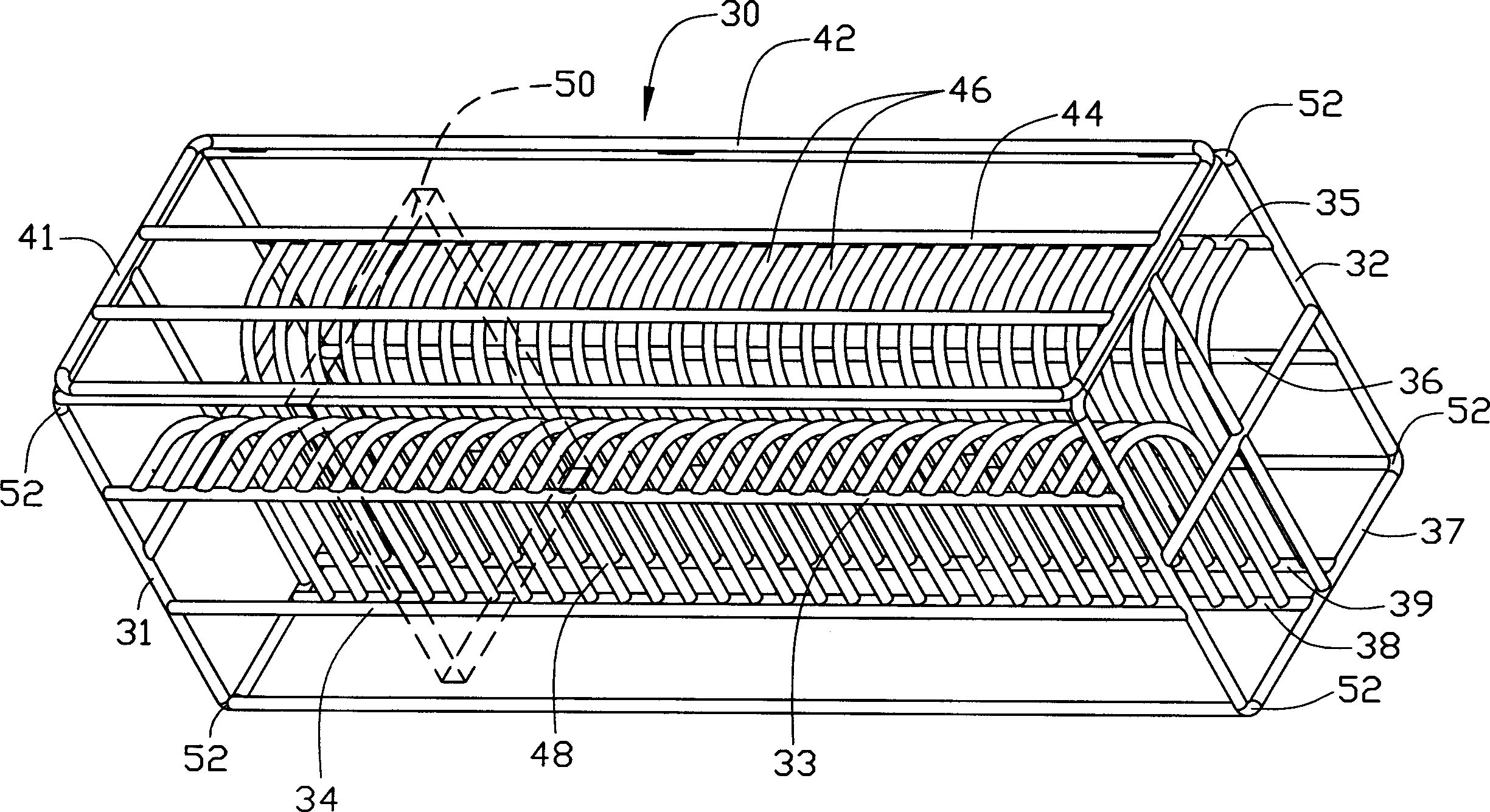

[0011] Such as figure 1 As shown, the realization of the vibration grinding, polishing and deburring method of the metal workpiece of the present invention needs to be completed by means of an electric vibrator 10 , a certain amount of abrasive 20 and several jigs 30 for holding the metal workpiece.

[0012] The vibration machine 10 can adjust the vibration frequency and has a horizontal vibration tank 12 . There is a rotatable stirring arm 14 at the bottom of the vibrating tank 12, and the inner wall of the vibrating tank 12 is lined with plastic wear-resistant material to prevent metal workpieces from being worn and scratched.

[0013] The abrasive material 20 is used for grinding metal workpieces, and it is contained in the vibrating tank 12 . In order to obtain a better grinding effect, the abrasive 20 can be composed of brown corundum particles with a particle size of 120 in three different shapes, among which spherical particles of Φ3-6mm account for 30-60% of the total...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com