Encapsulated solid acid, preparation and applications thereof

A solid acid, encapsulation technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of short action time, inability to ensure acid-liquid binding, poor construction effect, etc. The release rate and the effect of easy on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Prepare encapsulated solid acid by wrapping dry nitric acid powder with chitosan by solvent volatilization method.

[0059] (1) Disperse nitric acid powder and polymer stabilizer in an organic solvent to obtain solution A;

[0060] (2) Using a stirrer to stir and mix the material of the capsule wall and water at a speed of 1000-2000r / min to prepare solution B;

[0061] (3) Slowly mix the solutions A and B at a volume ratio of 25:1 to form an emulsion, and at the same time raise the temperature to 30-50°C and stir for 2-5 hours to form a white emulsion;

[0062] (4) Centrifuge the emulsion at a speed of 2000-3000r / min for 30min to obtain a precipitate, and then place the precipitate at minus 70°C and a pressure of 0.01-0.005Pa for 5-10h for freeze-drying to obtain Encapsulated solid acid with a particle size of 20-45 μm and a mass ratio of capsule wall to capsule core of 3:7.

Embodiment 2

[0063] Example 2: Encapsulated solid acid was prepared by wrapping dry nitric acid powder with chitosan by solvent evaporation method.

[0064] (1) Disperse nitric acid powder and polymer stabilizer in an organic solvent to obtain solution A;

[0065] (2) Using a stirrer to stir and mix the material of the capsule wall and water at a speed of 1000-2000r / min to prepare solution B;

[0066] (3) Slowly mix the solutions A and B at a volume ratio of 15:1 to form an emulsion, and at the same time raise the temperature to 30-50°C and stir for 2-5 hours to form a white emulsion;

[0067] (4) Centrifuge the emulsion at a speed of 2000-3000r / min for 30min to obtain a precipitate, and then place the precipitate at minus 70°C and a pressure of 0.01-0.005Pa for 5-10h for freeze-drying to obtain Encapsulated solid acid with a particle size of 20-45 μm and a mass ratio of capsule wall to capsule core of 1:2.

Embodiment 3

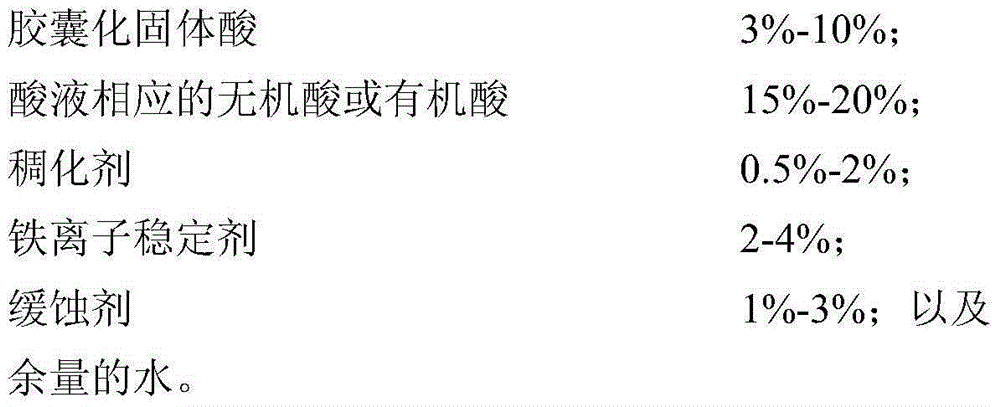

[0068] Example 3: Preparation of fracturing acidizing fluid.

[0069] Use the encapsulated solid acid prepared in Example 1 to prepare the fracturing acidizing fluid according to the amount in Table 1.

[0070] The prepared fracturing acidizing fluid was subjected to diversion experiment, core dissolution experiment and dynamic fluid loss measurement respectively, and the results are shown in Table 10.

[0071] Table 1 Composition of fracturing acidizing fluid by mass

[0072] Acid corresponding to inorganic acid hydrochloric acid 15% Encapsulated Solid Acid Dry powder nitric acid granules 3% Thickener xanthan gum 0.5% Iron ion stabilizer EDTA 1.0% corrosion inhibitor pentadecyl imidazoline 1.0% water margin

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com