Horizontal well plug removal and yield increase integrated technology and system

A technology for horizontal wells and processes, applied in the direction of flushing boreholes, boreholes/well components, cleaning tools, etc., can solve the problems of low plugging removal efficiency, poor flushing effect, high cost, etc., to improve reservoir permeability, economical and applicable Strong performance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

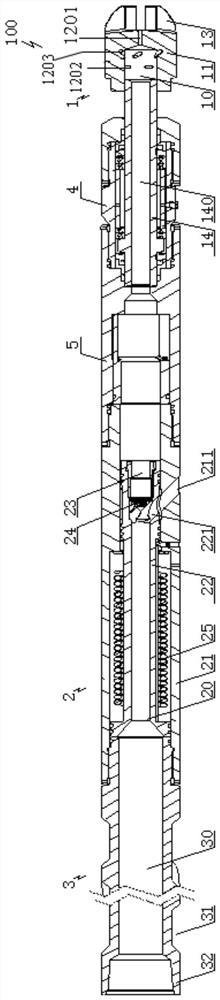

[0117] The present embodiment 1 provides a kind of downhole swirling flow shock plugging removal and flushing tool, such as figure 1 As shown, the downhole swirling impact plugging removal and flushing tool 100 includes:

[0118] The self-rotating impact part 1 includes the impact part body 11. The first center hole 10 with one end open and one end closed is arranged on the impact part body 11 in the axial direction. The impact part body 11 is provided with a horn-shaped outlet communicating with the first center hole 10 The axial nozzle 1201 of the impact part body 11 is provided with a mechanical claw 13 capable of rotating and crushing solid phase particles; the well flushing fluid flows through the first central hole 10 and the axial nozzle 1201 to generate a high-speed jet, which is harmful to the inside of the horizontal wellbore and the screen pipe. High-speed impact unblocking at the hole / casing blast hole; the mechanical claw 13 can mechanically crush the solid phase ...

Embodiment 2

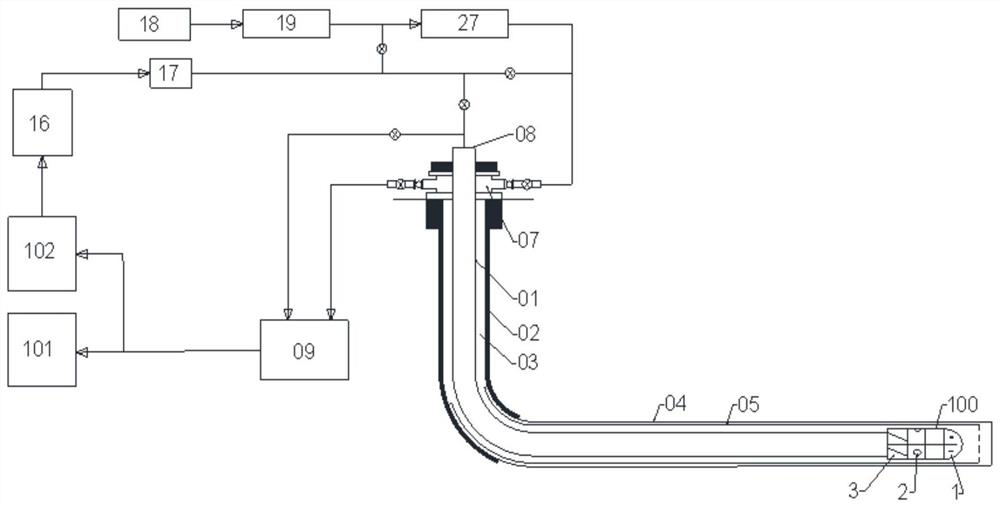

[0141] This embodiment provides an integrated system for removing plugging and increasing production of horizontal wells, such as figure 2 , Figure 4 and Figure 6 As shown, the system includes a first water storage tank 101, a second water storage tank 102, a liquid distribution tank 16, a pump truck 17, a nitrogen making truck 18, a booster truck 19, a sewage tank 09, a foam generator 27 and implementation The downhole swirling impact plugging removal and flushing tool 100 provided in Example 1;

[0142] One end of the tubing 01 of the horizontal well is connected to the female joint 32 of the swirl generation part 3 of the downhole swirl impact plugging removal and flushing tool 100, and in the initial state, the downhole swirl impact plugging removal flushing tool 100 Located near the landing point P01 of the horizontal well;

[0143] The second water storage tank 102 is connected to the inlet of the liquid distribution tank 16 through a pipeline, the outlet of the li...

Embodiment 3

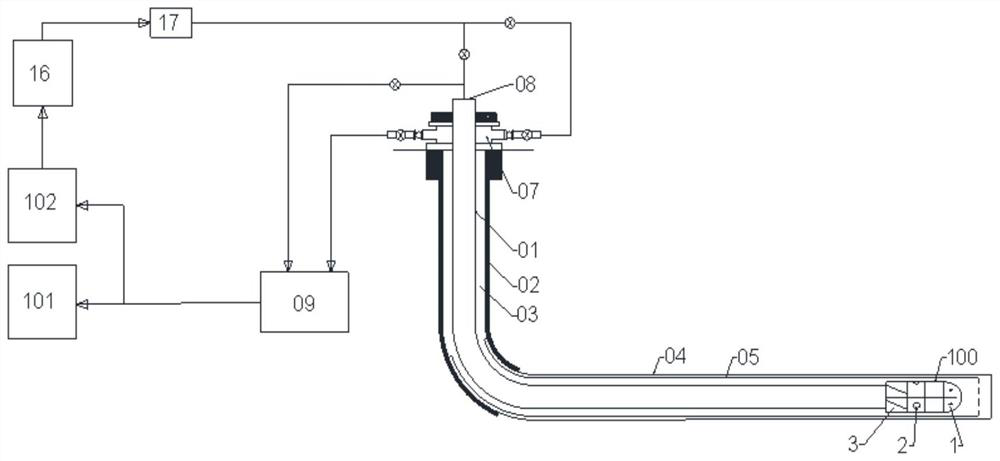

[0149] This embodiment provides an integrated system for removing plugging and increasing production of horizontal wells, such as image 3 , Figure 5 and Figure 6 As shown, the system includes a first water storage tank 101, a second water storage tank 102, a liquid distribution tank 16, a pump truck 17, a sewage tank 09, and the downhole swirling impact plugging removal and well cleaning tool 100 provided in Embodiment 1. ;

[0150] One end of the tubing 01 of the horizontal well is connected to the female joint 32 of the swirl generation part 3 of the downhole swirl impact plugging removal and flushing tool 100, and in the initial state, the downhole swirl impact plugging removal flushing tool 100 Located near the landing point P01 of the horizontal well;

[0151] The second water storage tank 102 is connected to the inlet of the liquid distribution tank 16 through a pipeline, the outlet of the liquid distribution tank 16 is connected to the inlet of the pump truck 17 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com