High-efficiency and low-consumption standard-reaching treatment method for wastewater from scale piggery raising

A technology for aquaculture wastewater and treatment methods, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large technical investment, poor operability, and high operating costs, and achieve High removal rate, high utilization rate, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

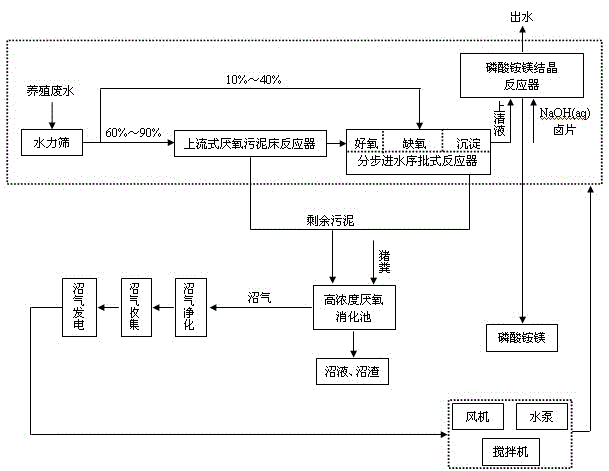

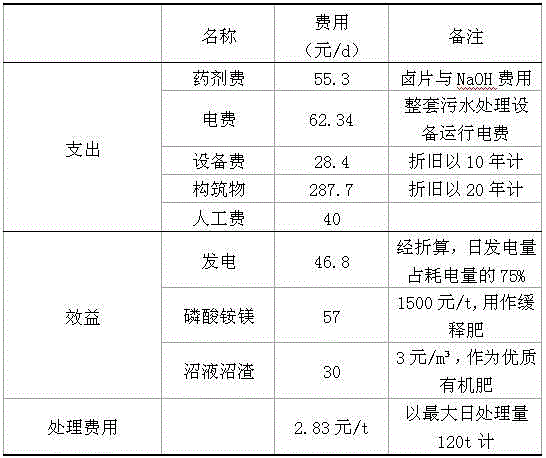

[0017] After the aquaculture wastewater is separated from the solid by the hydraulic sieve, 60% of the wastewater enters the upflow anaerobic sludge bed reactor to convert most of the COD and recover biogas. The aerobic section of the sequencing batch reactor is used for treatment, the DO is controlled at 2mg / L, and the reaction time is 5h. After the aerobic treatment is completed, 40% of the wastewater enters the anoxic section of the sequential batch reactor for denitrification and denitrification. At the same time, the alkalinity is replenished, the reaction time is 8 hours, and then it enters the precipitation section of the step-by-step water-inflow batch reactor, and the precipitation is 0.5 hours. Magnesium chloride, so that the molar ratio of Mg to P is 1.5, aeration and stirring to recover nitrogen and phosphorus nutrients, the reaction time is 1.5h, the active ingredient of the recovered product is magnesium ammonium phosphate, which is used as a slow-release fertiliz...

Embodiment 2

[0019] After the breeding wastewater is separated from solid and liquid by hydraulic sieving, 90% of the wastewater enters the upflow anaerobic sludge bed reactor to convert most of the COD and recover biogas, and the effluent of the upflow anaerobic sludge bed reactor enters the sub-step inflow The aerobic section of the sequencing batch reactor is used for treatment, the DO is controlled at 5 mg / L, and the reaction time is 7 hours. After the aerobic treatment is completed, 10% of the wastewater enters the anoxic section of the sequential batch reactor for denitrification and denitrification. At the same time, the alkalinity is replenished, the reaction time is 6 hours, and then it enters the precipitation section of the step-by-step batch reactor for precipitation, and the supernatant enters the magnesium ammonium phosphate crystallization reactor. Magnesium chloride, so that the molar ratio of Mg to P is 1.9, aeration and stirring to recover nitrogen and phosphorus nutrients...

Embodiment 3

[0021] After the breeding wastewater is separated from solid and liquid by hydraulic sieving, 70% of the wastewater enters the upflow anaerobic sludge bed reactor to convert most of the COD and recover biogas. The aerobic section of the sequencing batch reactor is used for treatment, the DO is controlled at 4 mg / L, and the reaction time is 6 hours. After the aerobic treatment is completed, 30% of the wastewater enters the anoxic section of the sequential batch reactor for denitrification and denitrification. At the same time, the alkalinity is replenished, the reaction time is 7 hours, and then it enters the precipitation section of the step-by-step batch reactor for precipitation, and the supernatant enters the magnesium ammonium phosphate crystallization reactor. Magnesium chloride, so that the molar ratio of Mg to P is 1.9, aeration and stirring to recover nitrogen and phosphorus nutrients, the reaction time is 1.5h, the active ingredient of the recovered product is magnesiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com