Method for recovering phosphonium compound from phosphorous excess sludge of urban sewage treatment plant

A technology for excess sludge and urban sewage, applied in phosphorus compounds, water/sludge/sewage treatment, sludge treatment, etc., to achieve the effect of facilitating management and operation, reducing sludge volume and reducing sludge treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

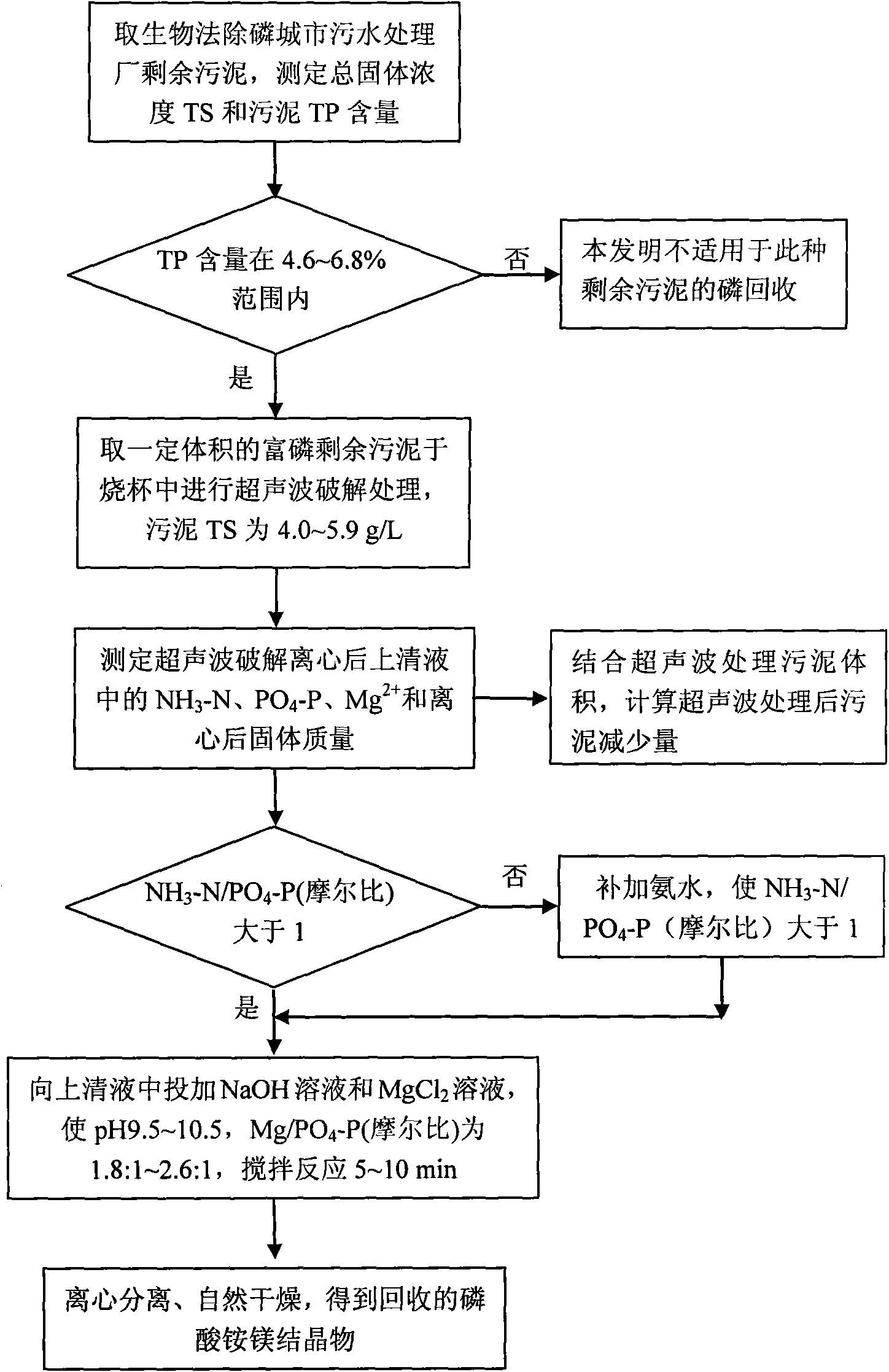

[0034] See attached figure 1 , A method for recovering phosphorus compounds from the phosphorus-rich surplus sludge of a municipal sewage treatment plant, the specific steps are:

[0035] a. Obtain phosphorus-rich surplus sludge from the biological phosphorus removal municipal sewage treatment system, analyze and determine the total phosphorus content and sludge concentration of the remaining sludge, and judge whether the phosphorus content is 4.6-6.8% (calculated as TS), and TS is 4.0~5.9g TS / L; if yes, proceed to step b; the specific analysis and determination process is: take a certain volume of sludge, determine the total phosphorus content in it, and take another volume of sludge to determine the TS content in it. As a result, the total phosphorus content per unit mass of sludge is obtained, that is, the phosphorus content; or the sludge is air-dried, and then a certain quality of sludge is taken to determine the total phosphorus content; the phosphorus content is the sludge ...

Embodiment 2

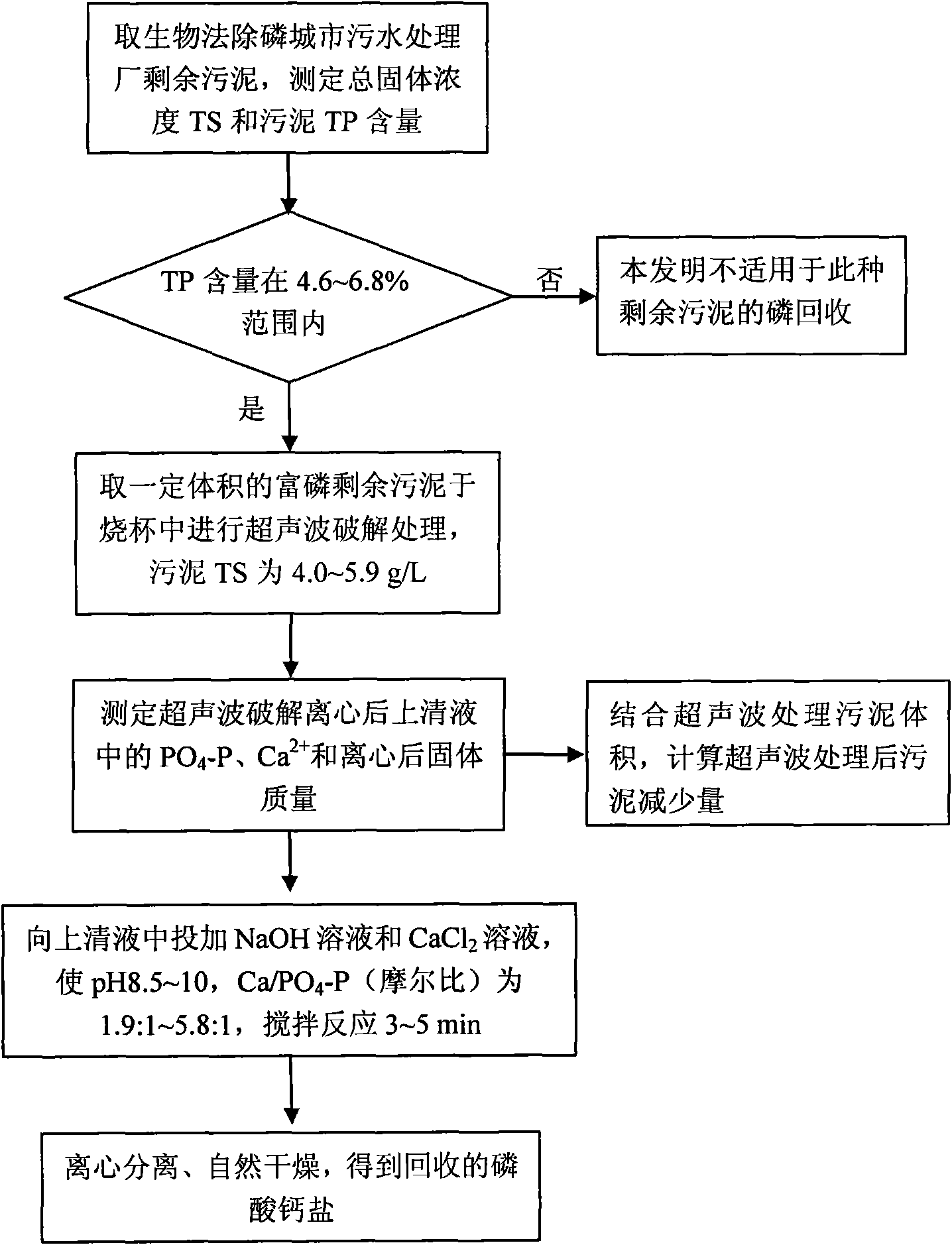

[0043] See attached figure 2 , A method for recovering phosphorus compounds from the phosphorus-rich surplus sludge of a municipal sewage treatment plant, the specific steps are:

[0044] a. Obtain phosphorus-rich surplus sludge from the biological phosphorus removal municipal sewage treatment system, analyze and determine the total phosphorus content and sludge concentration of the remaining sludge, and judge whether the phosphorus content is 4.6-6.8% (calculated as TS), and TS is 4.0~5.9gTS / L; if yes, go to step b;

[0045] b. Take 300mL of the phosphorus-rich surplus sludge obtained in step a and place it in a 400mL beaker under 150W (0.500W / mL) ultrasonic treatment for 50min, centrifuge (4000rpm, 20min), collect the supernatant and centrifuged solids;

[0046] c. According to the quality of the solids after centrifugation and the volume of the ultrasonic treated sludge, it can be seen that the quality of the sludge after ultrasonic treatment is reduced by 42.6%;

[0047] d. Anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com