Method for recovering phosphorus in phosphorus chemical wastewater by using struvite production technology

A production process, phosphorus chemical technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The effect of less and less interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

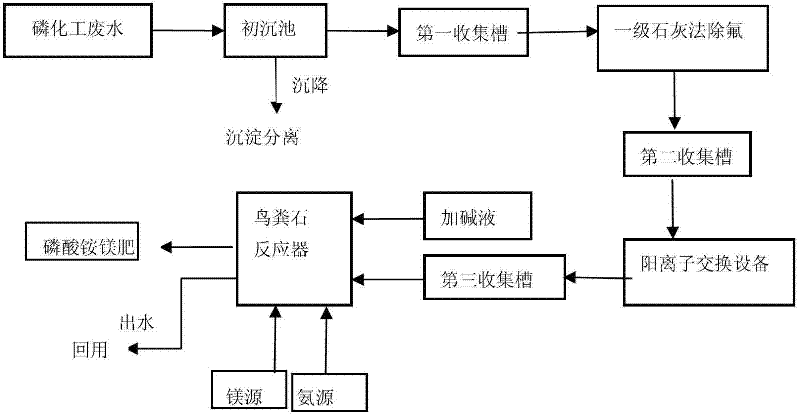

Method used

Image

Examples

Embodiment 1

[0023] The discharge of wastewater from a phosphogypsum slag yard in a chemical plant is 1200m3 / d. The phosphorus content in the wastewater is 4200mg / l, the fluorine content is 825mg / l, and the pH is 2.4. First, the wastewater from the phosphogypsum slag yard is passed through a primary sedimentation tank to remove impurities Precipitation, the treated wastewater is collected in the first collection tank; the wastewater in the first collection tank adopts the first-stage quicklime method to remove inorganic fluoride ions in the wastewater, adjusts the pH of the wastewater to 4, and removes the fluorine in the wastewater in the form of calcium fluoride precipitation. The removal rate of fluorine reaches 85%, and the treated wastewater is collected in the second collection tank. The wastewater in the second collection tank uses cation exchange equipment to remove inorganic cations in the wastewater, and the treated ion-exchange wastewater is collected in the third collection tank...

Embodiment 2

[0025] Example 2: Except that the molar ratio of magnesium / nitrogen / phosphorus added was 1.5:1.0:1, the others were the same as in Example 1, and about 7.4 t of crystalline magnesium ammonium phosphate granular fertilizer was produced. The phosphorus concentration in the effluent water of the reactor is 1.1mg / l, and the fluoride is 4mg / l, which can be directly discharged up to the standard.

Embodiment 3

[0026] Example 3: Except that the added magnesium / nitrogen / phosphorus molar ratio is 1.0:1.5:1, the others are the same as in Example 1, and about 7.3 tons of crystalline magnesium ammonium phosphate granular fertilizer are produced. The phosphorus concentration in the effluent water of the reactor is 1.0mg / l, and the fluoride is 6mg / l, which can be directly discharged up to the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com