Sewage treating apparatus of point-division feed water multilevel biomembrane reactor

A technology of biofilm reactor and sewage treatment equipment, applied in the field of environmental protection and sewage treatment, can solve the problems of unfavorable growth environment of dominant microbial flora, large amount of chemical phosphorus removal sludge, unsatisfactory denitrification effect, etc., to achieve management Convenience, high processing efficiency, and less land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

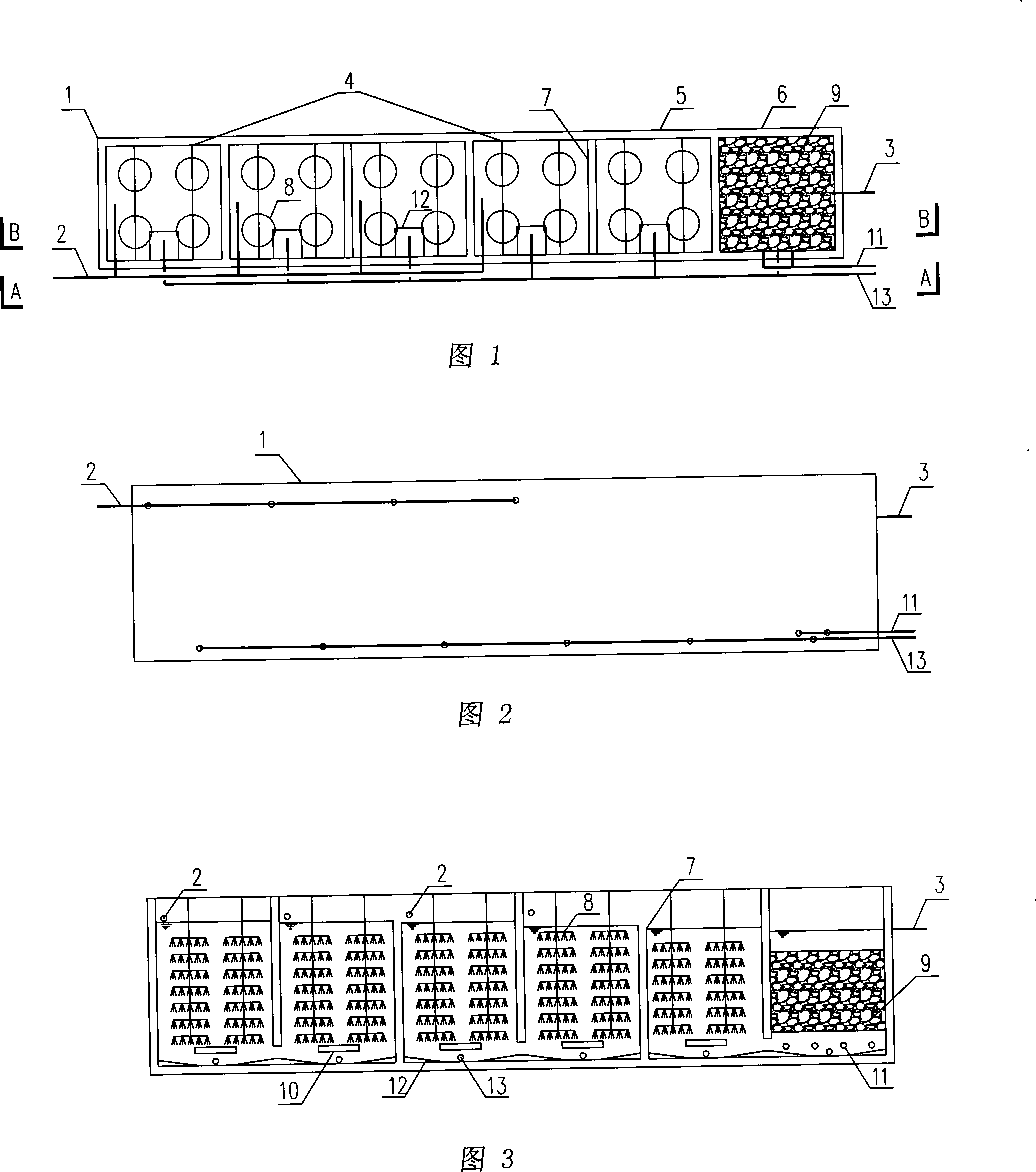

[0018] Referring to Fig. 1, Fig. 2 and Fig. 3, one embodiment of the present invention is: point-inflow multi-stage biofilm reactor sewage treatment equipment, including pool body 1, water inlet pipe 2, water outlet pipe 3 and mud discharge pipe 13 ; Generally, five partitions 7 are vertically arranged in the pool body 1, and the pool body 1 is divided into six series reaction pools, and each adjacent reaction pool is connected with the lower part and the upper part successively; wherein, the first four stages 4. Anaerobic and aerobic alternate operation is adopted. Semi-soft combined packing 8 is set in each pool. The fifth level 5 is an aerobic reaction zone with semi-soft combined packing 8 inside. The sixth level 6 is a filtration and sedimentation area. The iron-rich calcium filler 9 can strengthen phosphorus removal; the water inlet pipe 2 is set on the top of the pool body 1 and communicates with the water inlet of the first four-stage reaction pool, and adopts point-by-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com