Polymerized titanium tetrachloride inorganic polymeric flocculant and preparation method of inorganic polymeric flocculant

An inorganic polymer, titanium tetrachloride technology, applied in the field of environment and chemistry, can solve the problems of unstable properties of polysilicic acid, loss of flocculation efficiency, restricting the scope of application of polysilicic acid, etc., to achieve good flocculation effect and improve coagulation. Effectiveness, good water treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

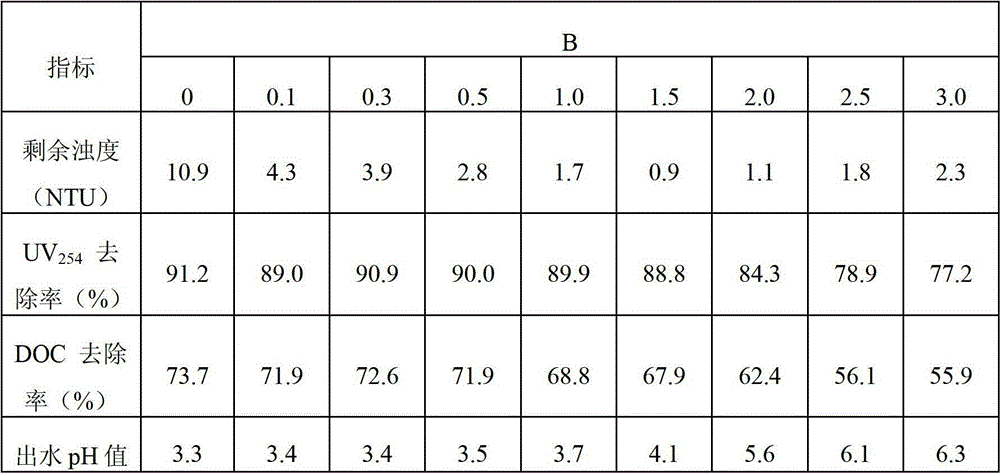

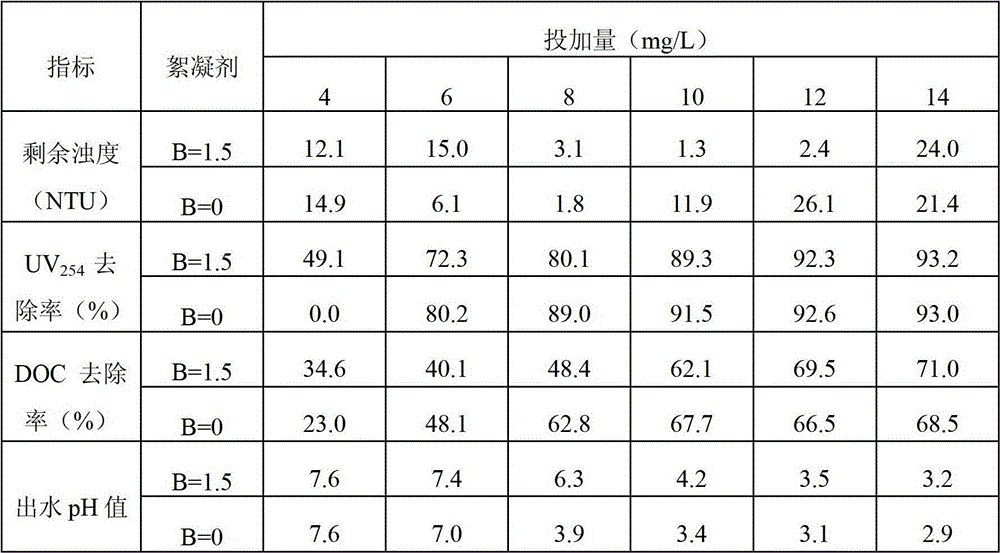

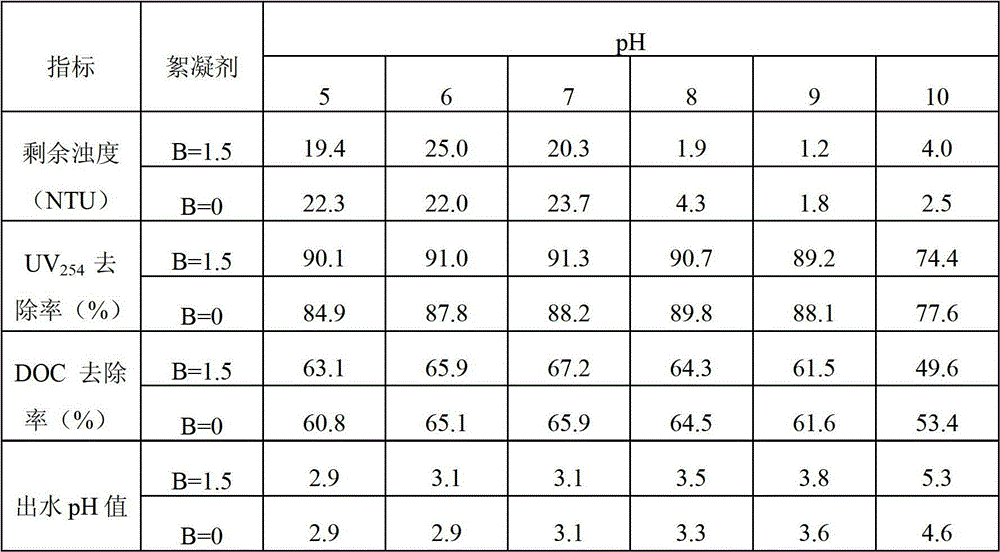

[0025] Measure 80mL of 99wt% titanium tetrachloride solution, add it dropwise to 316mL of ice water under the condition of 600rpm stirring, control the dropping speed to 1mL / min, keep stirring for 3h after the addition, and obtain a colorless transparent solution, namely It is 20wt% titanium tetrachloride solution; after that, measure 25.0ml of 20% titanium tetrachloride solution, and add 200g / L NaOH solution dropwise under vigorous stirring conditions, and the dropping volumes are respectively: 0.664mL, 1.992 mL, 3.32mL, 6.64mL, 9.96mL, 13.28mL, 16.6mL, 19.92mL, the dropping time are: 1, 3, 7, 15, 25, 35, 40, 50min. Continue to stir for 2~3h after the dropwise addition to obtain polymerized titanium tetrachloride inorganic polymer flocculants with alkalization degrees of 0.1, 0.3, 0.5, 1.0, 1.5, 2.0, 2.5, and 3.0 respectively. The prepared product is named as No.1 , No.2, No.3, No.4, No.5, No.6, No.7, No.8 said.

[0026] One of the application examples:

[0027] The No. 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com