Deep denitrification process for wastewater

A technology for deep denitrification and waste water, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Total nitrogen is difficult and other problems to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

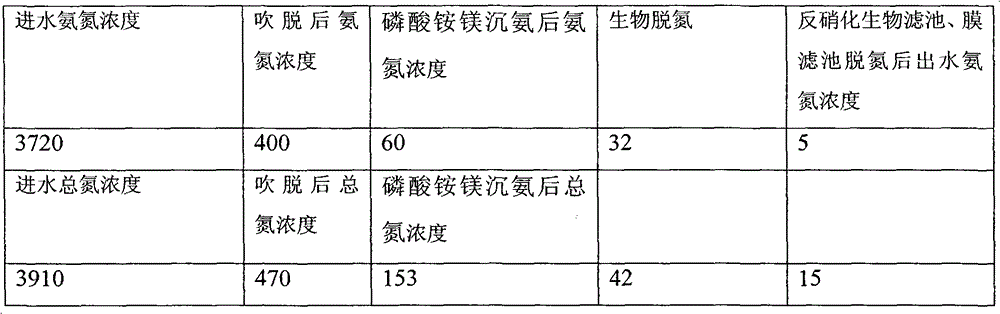

Embodiment 1

[0037] Embodiment 1: collect the wastewater containing high concentration of ammonia nitrogen from a petrochemical enterprise, and then process it according to the following steps:

[0038] (1) Microwave irradiation coagulation precipitation, high concentration ammonia nitrogen wastewater is added a certain amount of NaOH, and the pH value is adjusted to 11-13, flocculant and coagulant are coagulated and precipitated under alkaline conditions, and supernatant is obtained after precipitation liquid;

[0039] (2) the supernatant liquid obtained in step (1) is passed into the stripping tower subsequently; the top of the stripping tower is provided with a shower, and the middle part of the tower body is provided with a multi-layer packing layer, and the filler is: ceramsite, gac, Coke, quartz sand, anthracite or zeolite granular packing; Raschig ring, Pall ring, plastic spherical packing, semi-soft packing or elastic three-dimensional packing; waste water flows through the packing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com