Efficient-nitrogen-and-phosphorus-removing and resource recycling technology and device for iron phosphate production wastewater

A technology for producing wastewater, denitrification and phosphorus removal, applied in the field of water treatment, can solve the problems of increasing the salt content of wastewater, increasing the cost of wastewater treatment, and high treatment costs of ammonium and magnesium phosphate, and achieves the effect of reducing ammonia nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

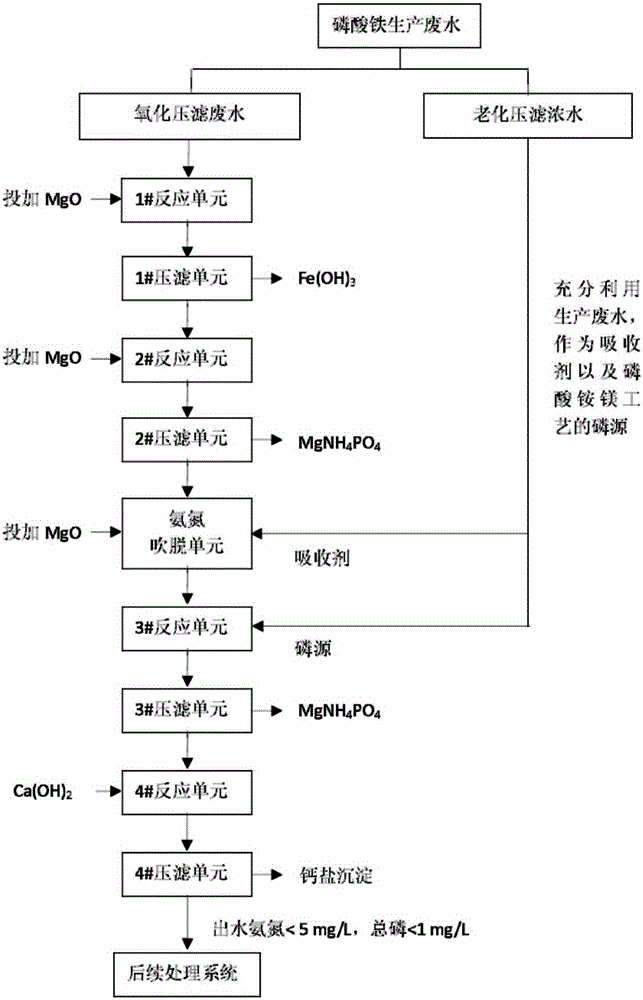

[0040] Please refer to figure 1 , the present embodiment provides a process and equipment for efficient denitrification and phosphorus removal and resource recovery of ferric phosphate production wastewater. The process specifically includes the following steps:

[0041]During the production of iron phosphate, two streams of wastewater will be produced, namely, oxidation press wastewater and aging press concentrate. Firstly, MgO is added in the first reaction unit to adjust the pH value of the oxidation filter press wastewater, so that iron ions in the wastewater can be precipitated in the form of ferric hydroxide and removed in the first filter press unit.

[0042] In the second reaction unit, continue to add MgO to the oxidation filter press wastewater after the above treatment, adjust the pH, precipitate nitrogen and phosphorus in the form of magnesium ammonium phosphate precipitation and remove them in the second press filter unit;

[0043] By continuing to add MgO to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com