Preparation method of lithium-sulfur battery cathode composite material

A lithium-sulfur battery and composite material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of high price and high raw material cost, and achieve the effect of reducing raw material cost, abundant sources, and reducing sulfur loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

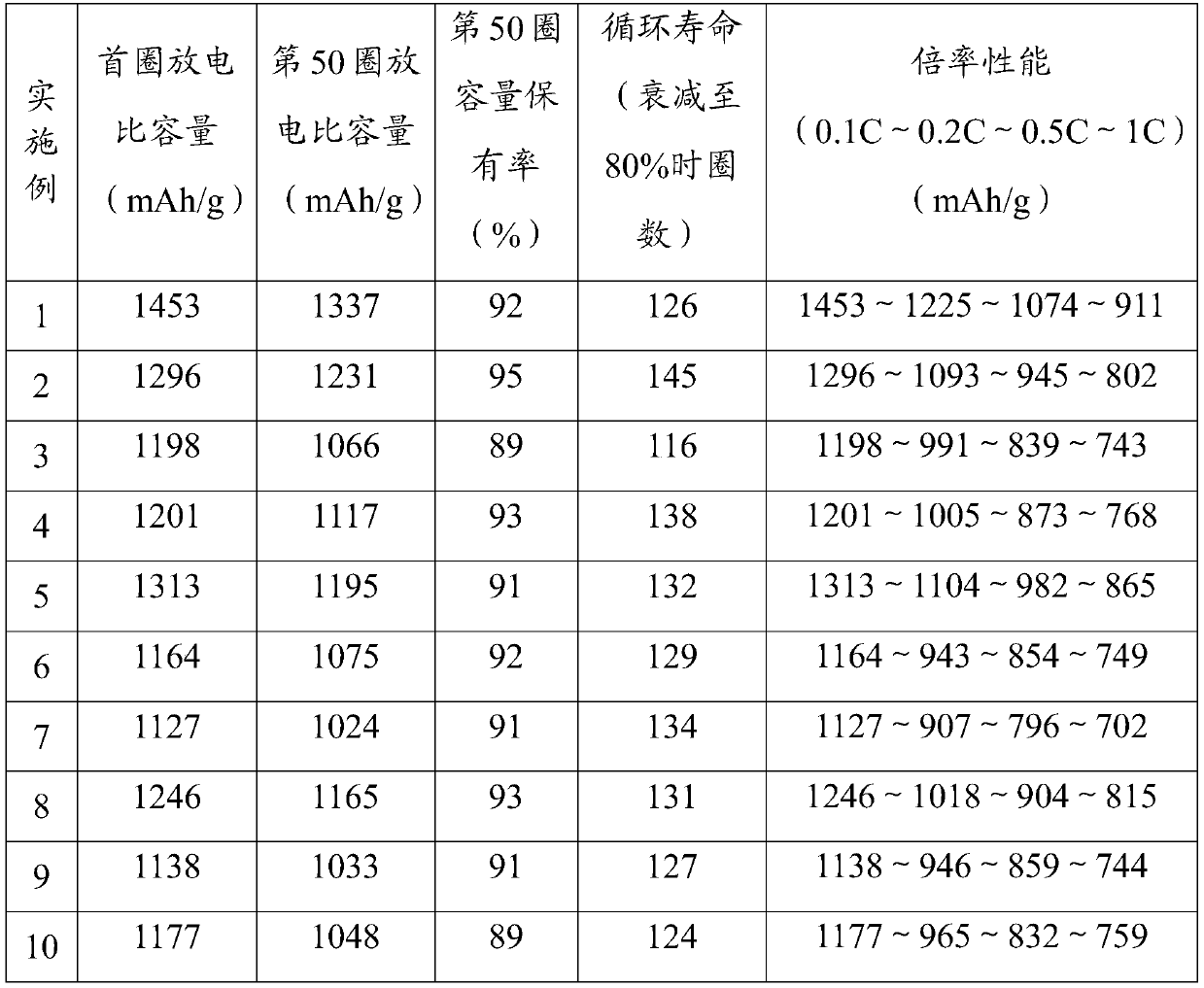

Examples

preparation example Construction

[0027] An embodiment of the present invention provides a preparation method of a lithium-sulfur battery cathode composite material, the preparation method comprising:

[0028] Mix clay minerals with acid solution and carry out etching reaction to obtain etching products;

[0029] loading transition metal ions on the etching product to obtain a product loaded with transition metal ions;

[0030] Mix and react sodium sulfide solution or ammonium sulfide solution with the transition metal ion product to obtain a sulfide surface-modified solid; when it is realized, calculate the S required for the reaction to form sulfide 2- The amount is prepared into a solution with sodium sulfide or ammonium sulfide, and the mass of the solution is 2 to 5 times the mass of the product loaded with transition metal ions.

[0031] mixing the sulfide surface-modified solid with an organic carbon source solution and then drying to obtain a dry product;

[0032] The dry product is heat-treated in a...

Embodiment 1

[0049] An embodiment of the present invention provides a preparation method of a lithium-sulfur battery cathode composite material, the preparation method comprising:

[0050] After mixing rectorite with hydrochloric acid with a concentration of 2 mol / L, stirring at 80° C. for 1 h for etching reaction to obtain etching products; wherein, the mass ratio of hydrochloric acid to rectorite is 2:1.

[0051] The obtained etching product was dried at 120° C. for 6 h after being washed and filtered.

[0052] The dry etching product is loaded with transition metal ions by an impregnation method of equal volume cobalt sulfide (soluble salt) to obtain a product loaded with transition metal ions; the mass ratio of cobalt sulfide to etching product is 1:20.

[0053] After the product loaded with transition metal ions was air-dried naturally, it was vacuum-dried at 80°C.

[0054] Mix the sodium sulfide solution with the transition metal ion product and fully mix and react at 40°C for 4 hou...

Embodiment 2

[0062] An embodiment of the present invention provides a preparation method of a lithium-sulfur battery cathode composite material, the preparation method comprising:

[0063] After mixing montmorillonite with nitric acid with a concentration of 2 mol / L, stirring at 50° C. for 3 h for etching reaction to obtain an etching product; wherein, the mass ratio of nitric acid to montmorillonite is 6:1.

[0064] The obtained etching product was dried at 120° C. for 6 h after being washed and filtered.

[0065] The dry etching product is loaded with transition metal ions by an equal volume manganese sulfide (soluble salt) impregnation method to obtain a loaded transition metal ion product; the mass ratio of cobalt sulfide to the etching product is 1:10.

[0066] After the product loaded with transition metal ions was air-dried naturally, it was vacuum-dried at 80°C.

[0067] Mix the sodium sulfide solution with the loaded transition metal ion product and fully mix and react at 50°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com