Processing method of waste iron phosphate

A treatment method, iron phosphate technology, applied in ammonium orthophosphate fertilizers, chemical instruments and methods, alkaline orthophosphate fertilizers, etc., can solve problems such as phosphorus pollution, achieve good processing performance, realize resource utilization, and increase specific surface area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

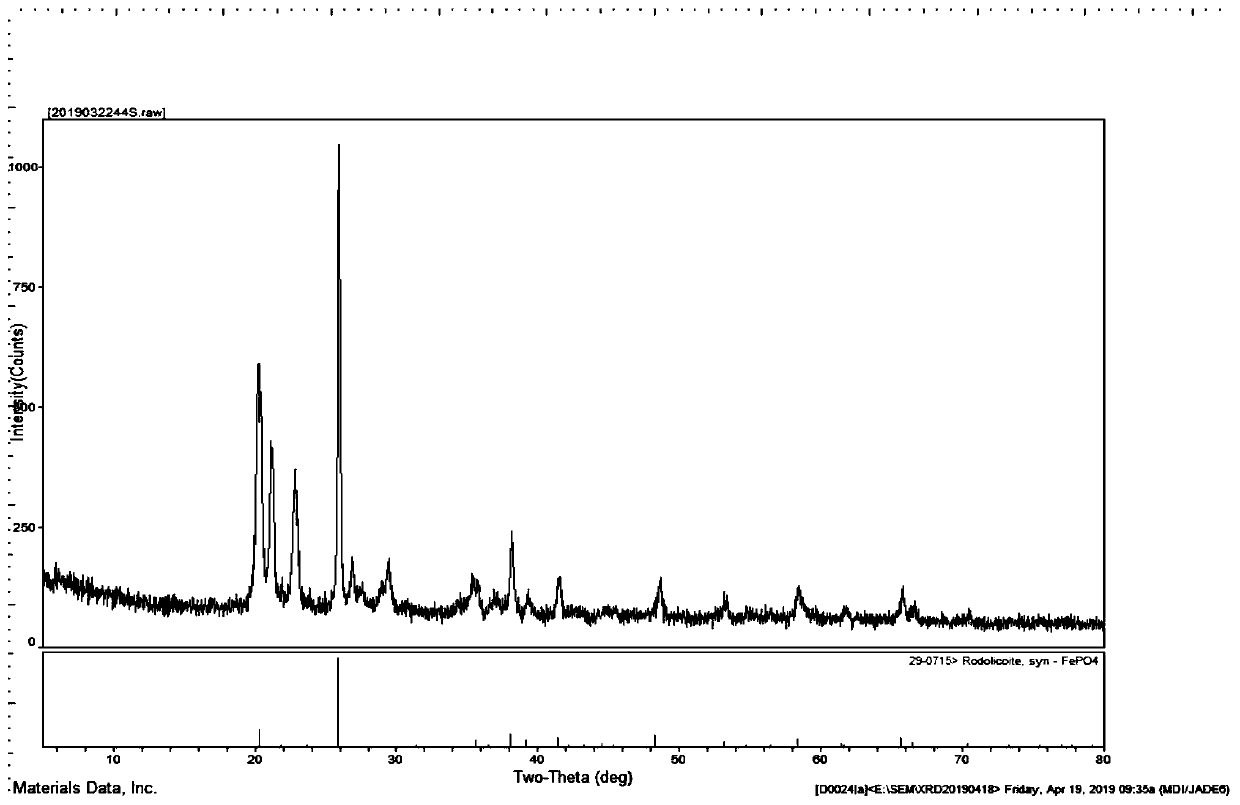

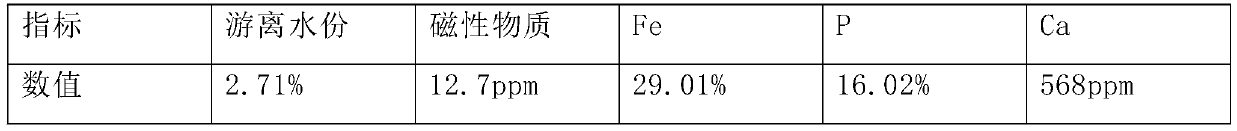

[0031] Get the waste ferric phosphate of certain factory, detect its each index, the result is as follows:

[0032]

[0033]

[0034] Add waste iron phosphate to phosphoric acid solution, heat up to 65°C after slurrying, react for 3 hours, and stir at a speed of 150r / min, then filter to obtain the first filtrate and first filter residue, waste iron phosphate and phosphoric acid in phosphoric acid solution The molar ratio is 1:1.08, and the concentration of phosphoric acid solution is 2.25mol / L.

[0035] The detection data of the first filtrate that obtains is as follows:

[0036] index pH Fe P Cd Ca value 1.01 116.32g / L 131.09g / L 25.8ppm 126ppm Mg Ni Cr Zn Cu co 3689ppm 197.5ppm 9.3ppm 87.4ppm 14.5ppm 18.7ppm

[0037] Add ammonium sulfide to the first filtrate obtained, react at a temperature of 50°C for 1.5h, and stir at a speed of 300r / min, then filter to obtain the second filtrate and the second filter...

Embodiment 2

[0051] Add waste ferric phosphate to phosphoric acid solution, heat up to 65°C after slurrying, react for 4 hours, and stir at a speed of 160r / min, then filter to obtain the first filtrate and the first filter residue, add ammonium sulfide to the obtained first filtrate, The temperature is 52°C for 1.5h, the stirring speed is 250r / min, and then filtered to obtain the second filtrate and the second filter residue, the second filtrate is mixed with urea, and the temperature is 99°C and the stirring speed is 150r / min. The pH is 1.95, and then filtered to obtain a third filter residue and a third filtrate, and the third filter residue is dried and then calcined to obtain battery-grade anhydrous iron phosphate.

[0052] The waste ferric phosphate is crushed after drying before phosphoric acid is dissolved, passed through an 80-mesh sieve, and the obtained under-sieve is subjected to electromagnetic iron removal to obtain a material with a magnetic substance ≤ 1 ppm. The magnetic sub...

Embodiment 3

[0062] Add waste ferric phosphate to phosphoric acid solution, heat up to 65°C after slurrying, react for 4 hours, and stir at a speed of 180r / min, then filter to obtain the first filtrate and the first filter residue, add ammonium sulfide to the obtained first filtrate, The temperature is 48°C for 1.5h, the stirring speed is 300r / min, and then filtered to obtain the second filtrate and the second filter residue, the second filtrate is mixed with urea, and the temperature is 98°C, and the stirring speed is 150r / min. The pH is 2.05, and then filtered to obtain a third filter residue and a third filtrate, and the third filter residue is dried and then calcined to obtain battery-grade anhydrous iron phosphate.

[0063] The waste ferric phosphate is crushed after being dried before phosphoric acid is dissolved, passed through a 100-mesh sieve, and the obtained under-sieve is subjected to electromagnetic iron removal to obtain a material with a magnetic substance ≤ 1 ppm. The magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com