Flame retardant based on organic silicon resin

A silicone and flame retardant technology, applied in the field of silicone flame retardants, can solve problems such as poor compatibility, elimination, and poor heat resistance, and achieve improved flame retardant performance, improved bending strength and impact strength, and good hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

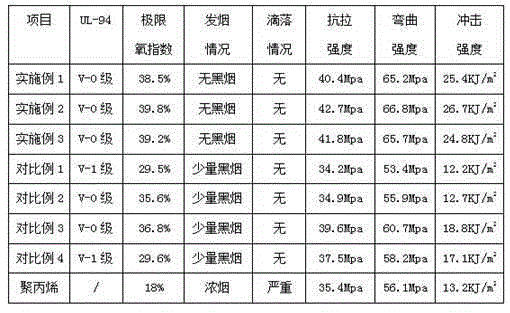

Examples

Embodiment 1

[0031] A flame retardant based on silicone resin, the raw materials in parts by weight are: 30 parts of silicone resin, 20 parts of silicone elastomer, 10 parts of amine vulcanization, 5 parts of antimony dioxide, 1 part of silane coupling agent, hydrogen 5 parts of sodium oxide, 80 parts of alcohol, 10 parts of magnesium hydroxide, 5 parts of diatomaceous earth, 5 parts of polyphosphorus oxide, 40 parts of deionized water, 2 parts of flame retardant synergistic composition; the flame retardant synergistic composition The components according to parts by weight are: 1 part of carbon nanotube and 1 part of nano mesoporous molecular sieve.

[0032] The preparation method of the flame retardant based on silicone resin, the specific steps are:

[0033] (1) First crush the silicone resin and silicone elastomer into particles with a particle size of no more than 2mm, and then mix them with sulfide amine, antimony dioxide, silane coupling agent, sodium hydroxide, magnesium hydroxide,...

Embodiment 2

[0039] A flame retardant based on silicone resin, the raw materials in parts by weight are: 40 parts of silicone resin, 30 parts of silicone elastomer, 15 parts of amine vulcanization, 6 parts of antimony dioxide, 3 parts of silane coupling agent, hydrogen 8 parts of sodium oxide, 100 parts of alcohol, 13 parts of magnesium hydroxide, 8 parts of diatomaceous earth, 10 parts of polyphosphorus oxide, 50 parts of deionized water, 13 parts of flame retardant synergistic composition; the flame retardant synergistic composition The components in parts by weight are: 2 parts of carbon nanotubes, 4 parts of nanometer mesoporous molecular sieves, 3 parts of micron silicon nitride, and 4 parts of micron silicon carbide.

[0040] The preparation method of the flame retardant based on silicone resin, the specific steps are:

[0041](1) First crush the silicone resin and silicone elastomer into particles with a particle size of no more than 2mm, and then mix them with sulfide amine, antimo...

Embodiment 3

[0047] A flame retardant based on silicone resin, the raw materials in parts by weight are: 50 parts of silicone resin, 40 parts of silicone elastomer, 205 parts of vulcanized amine, 7 parts of antimony dioxide, 5 parts of silane coupling agent, hydrogen 10 parts of sodium oxide, 120 parts of alcohol, 15 parts of magnesium hydroxide, 85 parts of diatomaceous earth, 10 parts of polyphosphorus oxide, 60 parts of deionized water, 20 parts of flame retardant synergistic composition; the flame retardant synergistic composition The components in parts by weight are: 3 parts of carbon nanotubes, 5 parts of nanometer mesoporous molecular sieves, 4 parts of micron silicon nitride, and 5 parts of micron silicon carbide.

[0048] The preparation method of the flame retardant based on silicone resin, the specific steps are:

[0049] (1) First crush the silicone resin and silicone elastomer into particles with a particle size of no more than 2mm, and then mix them with sulfide amine, antim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com