Preparation method of nitrogen and carbon doped cobalt molybdenum sulfide counter electrode catalyst with adjustable yolk-shell structure

A cobalt molybdenum sulfide, shell structure technology, applied in physical/chemical process catalysts, chemical instruments and methods, circuits, etc., can solve the problems of shedding DSSC battery circuits, poor adhesion of carbon materials, and decreased battery efficiency, etc. Effects of stability, enhanced specific surface area, and excellent electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

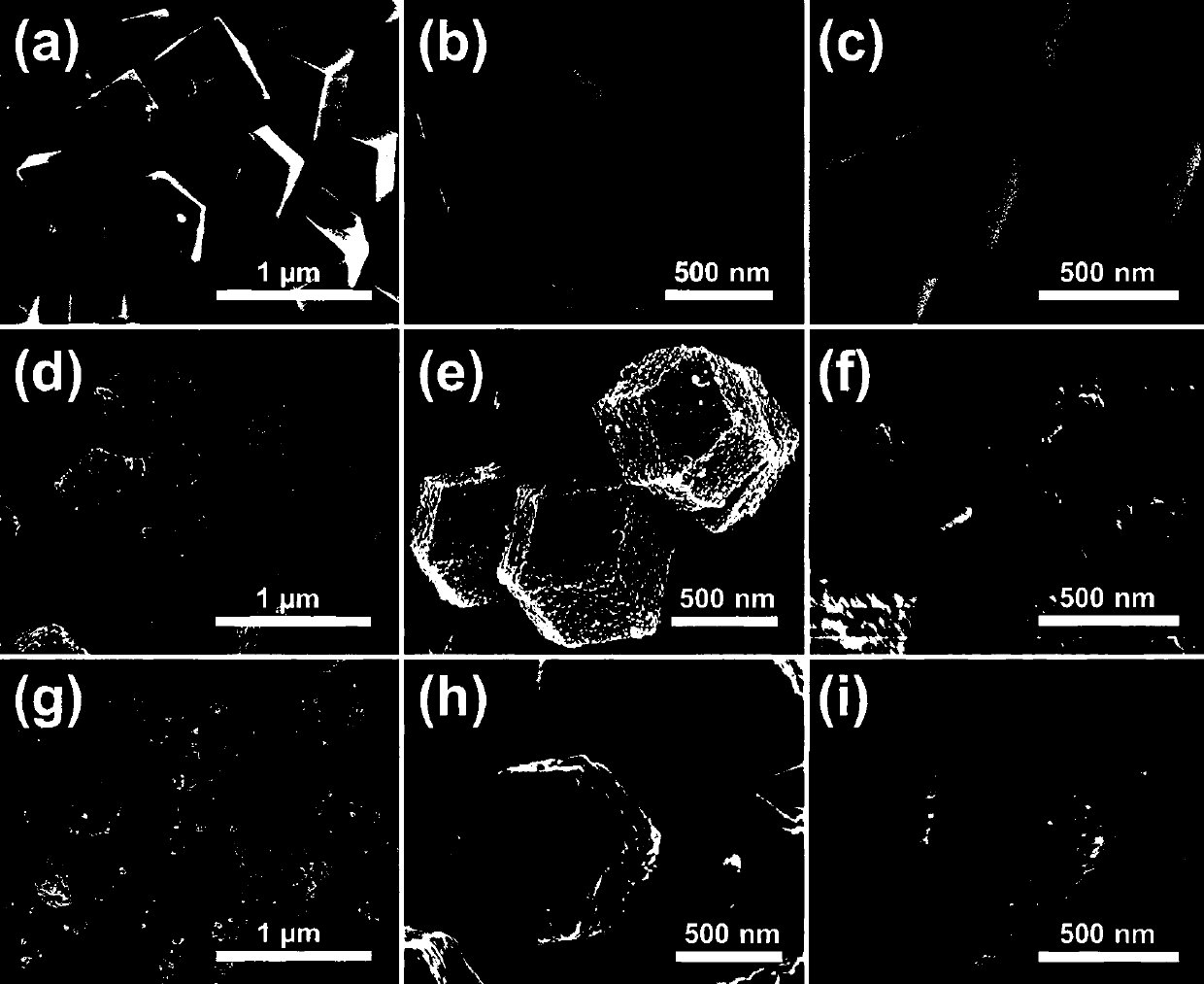

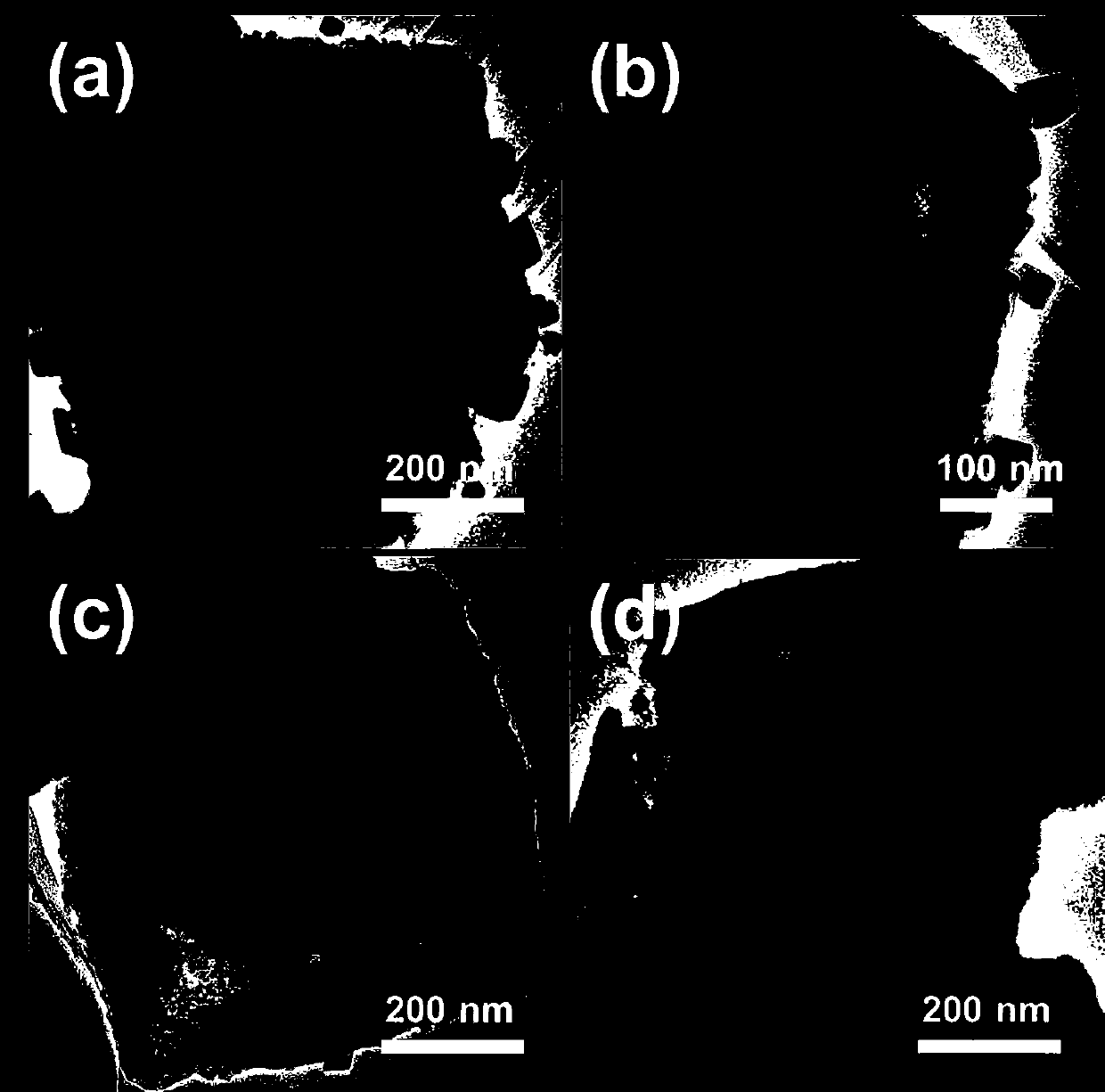

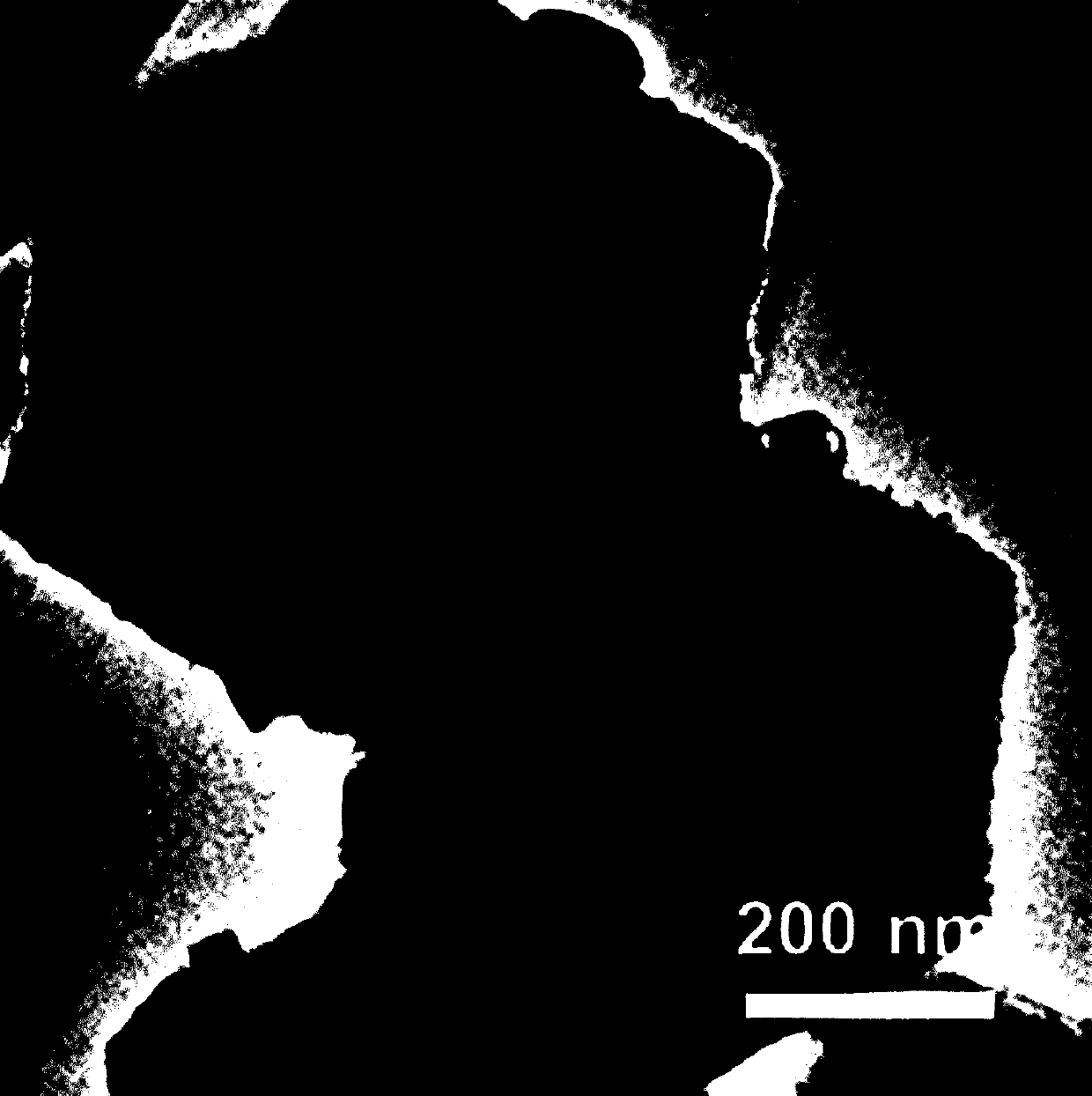

[0032] Dissolve 4.5 g of cobalt nitrate hexahydrate and 4.5 g of 2-methylimidazole in 450 mL of methanol respectively. After the two solutions are completely dissolved, mix the two solutions uniformly, stir for 10 min and then stand for 24 h, centrifuge and dry to obtain purple ZIF-67 polyhedron. Dissolve 45 mg of ammonium molybdate and 300 µL of 20% ammonium sulfide solution in 5 mL of water, add 20 µL of ammonia, and in an oil bath at 50 ℃ for 0.5 h to obtain an ammonium thiomolybdate solution. Disperse 300 mg of ZIF-67 polyhedron in 100 mL of absolute ethanol, mix with ammonium thiomolybdate solution and stir at room temperature for 0.5 h. After centrifugation, washing and drying, a purple black cobalt molybdenum sulfide coated ZIF-67 intermediate ZIF-67 is obtained. @Co-MoS 2 . Add 100 mg ZIF-67@Co-MoS 2 After the intermediate and 200 mg sulfur powder are ground and mixed uniformly, they are placed in a porcelain boat and heated to 300 ℃ in a tube furnace for 1.5 h at a he...

Embodiment 2

[0034] Dissolve 4.64 g of cobalt nitrate hexahydrate in 464 mL of methanol, and dissolve 5.24 g of 2-methylimidazole in 524 mL of methanol. After the two solutions are completely dissolved, mix the two solutions uniformly, stir for 10 minutes and then stand for 24 hours, centrifuge Dry to obtain purple ZIF-67 polyhedron. Dissolve 70 mg of ammonium molybdate and 500 µL of 20% ammonium sulfide solution in 7.8 mL of water, add 36 µL of ammonia, and in an oil bath at 60 ℃ for 0.5 h to obtain an ammonium thiomolybdate solution. Disperse 300 mg of ZIF-67 polyhedron in 100 mL of absolute ethanol, mix with ammonium thiomolybdate solution and stir at room temperature for 0.5 h. After centrifugation, washing and drying, a purple black cobalt molybdenum sulfide coated ZIF-67 intermediate ZIF-67 is obtained. @Co-MoS 2 . Add 100 mg of the above ZIF-67@Co-MoS 2 After the intermediate and 200 mg sulfur powder are ground and mixed uniformly, they are placed in a porcelain boat and heated to 3...

Embodiment 3

[0036] Dissolve 4.64 g of cobalt nitrate hexahydrate in 464 mL of methanol, dissolve 5.24 g of 2-methylimidazole in 524 mL of methanol, mix the two solutions uniformly after they are completely dissolved, stir for 10 minutes and then stand for 24 hours, centrifuge Dry to obtain purple ZIF-67 polyhedron. Dissolve 140 mg of ammonium molybdate and 1077 µL of 20% ammonium sulfide solution in 15.6 mL of water, add 83 µL of ammonia, and in an oil bath at 60 ℃ for 0.5 h to obtain an ammonium thiomolybdate solution. Disperse 300 mg of ZIF-67 polyhedron in 100 mL of absolute ethanol, mix with ammonium thiomolybdate solution and stir at room temperature for 1 h. After centrifugation, washing and drying, a purple-black cobalt-molybdenum sulfide coated ZIF-67 intermediate ZIF-67 is obtained. @Co-MoS 2 . Add 100 mg of the above ZIF-67@Co-MoS 2 After the intermediate and 200 mg sulfur powder are ground and mixed uniformly, they are placed in a porcelain boat and heated to 400 ℃ in a tube fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Photoelectric conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com