Method and device for deeply purifying by-product ammonium sulfate solution from diachylon ammonium desulphurization

A technology of ammonium sulfate solution and desulfurization by-products, applied in the field of resource recovery and utilization technology, to achieve the effect of avoiding toxic hydrogen sulfide gas and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

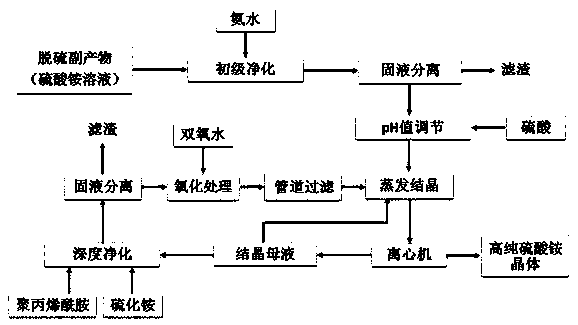

Method used

Image

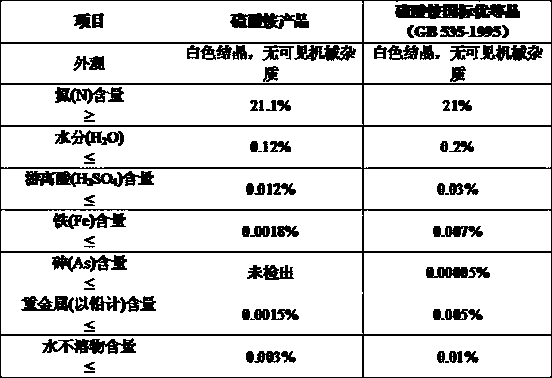

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

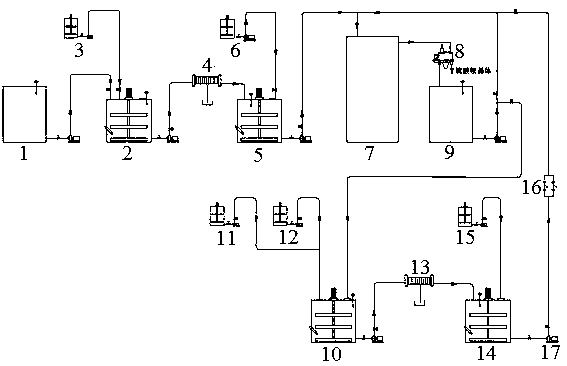

[0029] like figure 2 As shown, the equipment of the present invention includes desulfurization by-product storage tank 1, ammonia water quantitative addition device 3, primary purification reactor 2, primary purification filter 4, sulfuric acid quantitative addition device 6, pH value adjustment reactor 5, evaporation crystallizer 7 , centrifuge 8, crystallization mother liquor storage tank 9, ammonium sulfide quantitative dosing device 11, polyacrylamide quantitative addition device 12, deep purification reactor 10, deep purification filter 13, hydrogen peroxide quantitative addition device 15, oxidation reactor 14, Pipeline filter 16, delivery pump 17; desulfurization by-product storage tank 1, primary purification reactor 2, primary purification filter 4, pH adjustment reactor 5, evaporation crystallizer 7, centrifuge 8, crystallization mother liquor stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com