Tin sulfide/graphene sodium ion battery composite cathode material and preparation method thereof

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that the cycle life of materials cannot meet the requirements of practical applications, it is difficult to achieve controllable preparation of materials, and the poor conductivity of sulfides. Excellent rate performance and cycle performance, high capacity, and the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

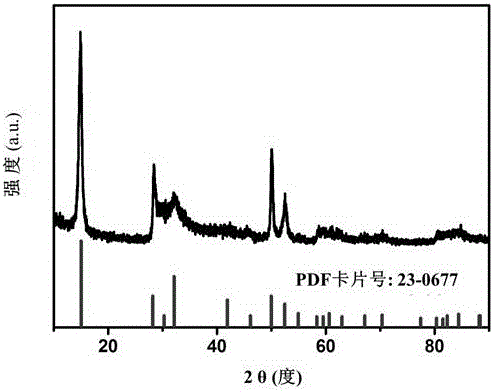

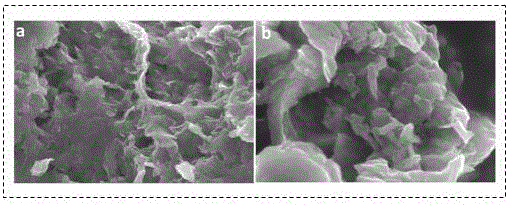

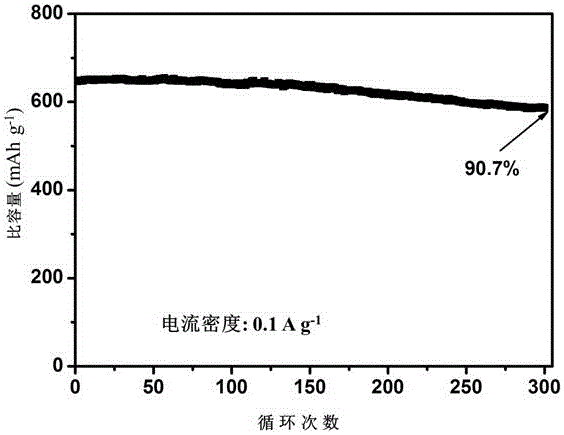

[0032] Stir and dissolve 0.01 g of commercial tin sulfide in 372.7 g of 1 wt. % ammonium sulfide solution (the molar ratio of tin sulfide to ammonium sulfide is 0.001:1), and add 0.1 mg ml -1 The graphene oxide solution was prepared so that the mass ratio of graphene oxide to tin sulfide was 0.001:1, and it was ultrasonically treated for 1 min to make it fully dispersed, then quickly frozen with liquid nitrogen, and then freeze-dried for 6 h to obtain the precursor. The precursor was placed in a nitrogen atmosphere at 250 o C sintered for 24 h to obtain tin sulfide / graphene composites. The physical and chemical properties of tin sulfide / graphene composites can be seen in figure 1 with figure 2 . After comparing with the standard reference card, it can be seen that XRD shows that the tin sulfide / graphene composite material synthesized by this method is consistent with the standard card. SEM shows that the composite material is loose and porous, and the tin sulfide particle...

Embodiment 2

[0034] Stir and dissolve 40 mmol of commercial tin sulfide in 3.4 g of 20 wt. % ammonium sulfide solution (the molar ratio of tin sulfide to ammonium sulfide is 4:1), and add 30 mg ml of -1 Graphene oxide solution, so that the mass ratio of graphene oxide to tin sulfide is 0.5:1, and ultrasonically treated for 600 min to make it fully dispersed and uniform. The sonicated solution was rapidly refrigerated with dry ice and then vacuum freeze-dried for 36 h to obtain the precursor. The precursor was then placed in an argon atmosphere at 500 o C was sintered for 1 h to obtain tin sulfide / graphene composites. The physical and chemical properties of tin sulfide / graphene composites can be seen in Figure 4 with Figure 5 . Figure 4 The SEM and TEM results show that the composite of tin sulfide and graphene is relatively uniform. Figure 5 for a current density of 1 A g -1 The cycle charge-discharge curve below shows that the composite material has a current density specific ca...

Embodiment 3

[0036] Dissolve 4 mmol of commercial tin sulfide in 13.68 g of ammonium sulfide solution with a concentration of 11.5 wt. % (the molar ratio of tin sulfide to ammonium sulfide is 2:1), and add 15 mg ml of -1 Graphene oxide solution, so that the mass ratio of graphene oxide and tin sulfide in the graphene oxide solution is 0.25:1, and ultrasonic treatment for 300 min to make it fully dispersed and uniform, and then use microwave vacuum freeze-drying after freezing by laser rapid refrigeration technology72 h to get the precursor. The precursor at 3% vol.H 2 / N 2 Atmosphere 375 oC was sintered for 5 h to obtain tin sulfide / graphene material. Assemble the resulting product into a button battery to measure its charge and discharge capacity, and perform 3 A g in the range of 0.01-2.5V -1 The cycle life test under the condition is obtained as Image 6 The shown tin sulfide / graphene material at a current density of 3 A g -1 The cycle charge and discharge curve below shows that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com