Treatment device and method for incineration gas of cremator

A technology of incineration flue gas and treatment device, which is applied in the field of treatment device for cremation machine incineration flue gas, and can solve problems such as low chimney height, dust removal treatment, and human health hazards in the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

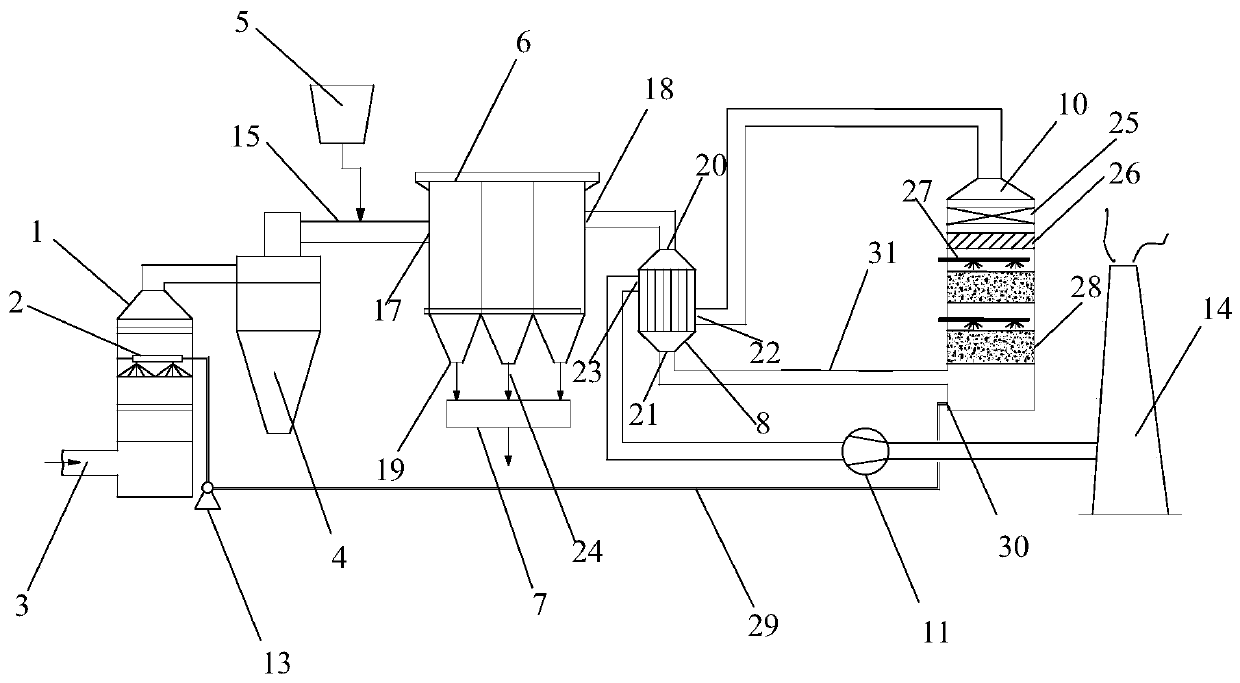

[0046] Please refer to figure 1 Shown: the present invention provides a treatment device for incineration flue gas of cremation machine,

[0047] A treatment device for flue gas incinerated by a cremator, comprising:

[0048] Quenching tower 1 has an inlet and an outlet (not shown in the figure), and the inlet 3 of the quenching tower is used to receive the flue gas after the incineration of the cremator;

[0049] The spark interceptor 4 has an inlet and an outlet (not shown in the figure), and the entrance of the spark interceptor 4 communicates with the outlet of the quench tower 1 through the flue, and the spark interceptor 4 is used for trapping the smoke processed by the quench tower 1 Combustion in the air;

[0050] The bag dust collector 6 has a flue gas inlet 17, a flue gas outlet 18, and an ash outlet 19. The flue gas inlet 17 communicates with the outlet of the Mars interceptor 4 through a straight flue 15; An activated carbon injection device 5 is arranged betwee...

Embodiment 2

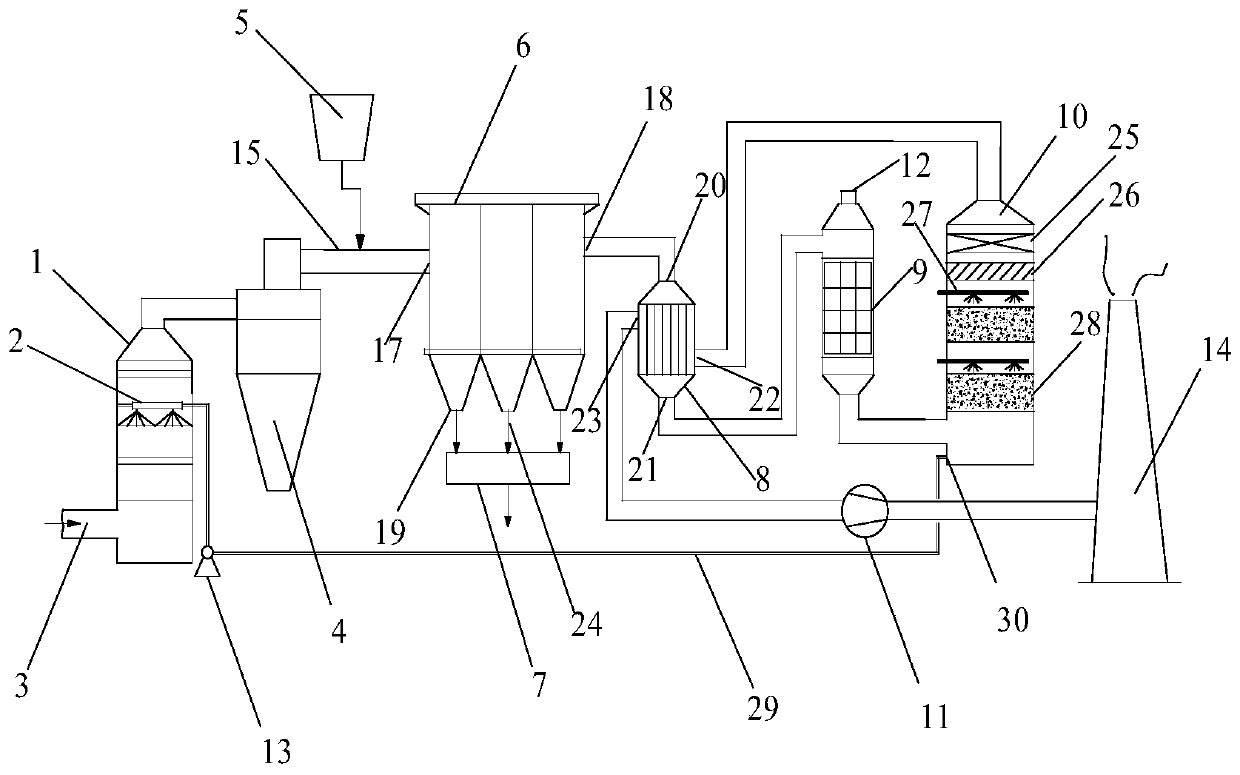

[0068] Such as figure 2 As shown, compared with Embodiment 1, the treatment device for the incineration flue gas of the cremation machine also includes a low-temperature plasma reaction device 9, which is arranged between the heat exchanger 8 and the absorption device 10, and the low-temperature plasma reaction device 9 has Inlet and outlet (not shown in the figure), the inlet of the low-temperature plasma reaction device 9 communicates with the hot gas outlet 21 of the heat exchanger through the flue; The pollutants in the flue gas treated by the heat generator undergo redox reactions.

[0069]In other embodiments, the low-temperature plasma reaction device can be replaced by an ozone generator, and the ozone generator has an inlet and an outlet, and the inlet of the ozone generator is connected with the gas outlet of the oxygen cylinder through a connecting pipe; the ozone generator The outlet of the main flue communicates with the main flue 31 through the flue, and is use...

Embodiment 3

[0105] Take the flue gas incineration of a cremation machine in a funeral home as the implementation, the flue gas value is the flue gas parameter after the quench tower, and the flue gas volume is 5000m 3 / h, oxygen content 14-18%, moisture content 15-20%, odor concentration 5600, SO 2 Average concentration 60mg / Nm 3 , NO x Average concentration 120mg / Nm 3 , the average value of smoke and dust is 160mg / Nm 3 , average value of dioxin 2.0ng TEQ / Nm 3 , the temperature of the flue gas is 172°C, and it is processed by the above-mentioned cremator incineration flue gas treatment device, wherein the operating frequency and operating voltage of the plasma power supply in the low-temperature plasma reaction device are both zero.

[0106] The specific processing steps are as follows: the flue gas incinerated by the above-mentioned cremation machine is transported from the inlet to the quenching tower, and the liquid is sprayed to the flue gas in the tower through the quenching spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com