Air purifying device

An air purification device and the technology of the purification device, which are applied in the field of air purification, can solve the problems of difficult flour storage, high air velocity, and flying flour, etc., and achieve excellent purification effect, avoid too much noise, and purify the air smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

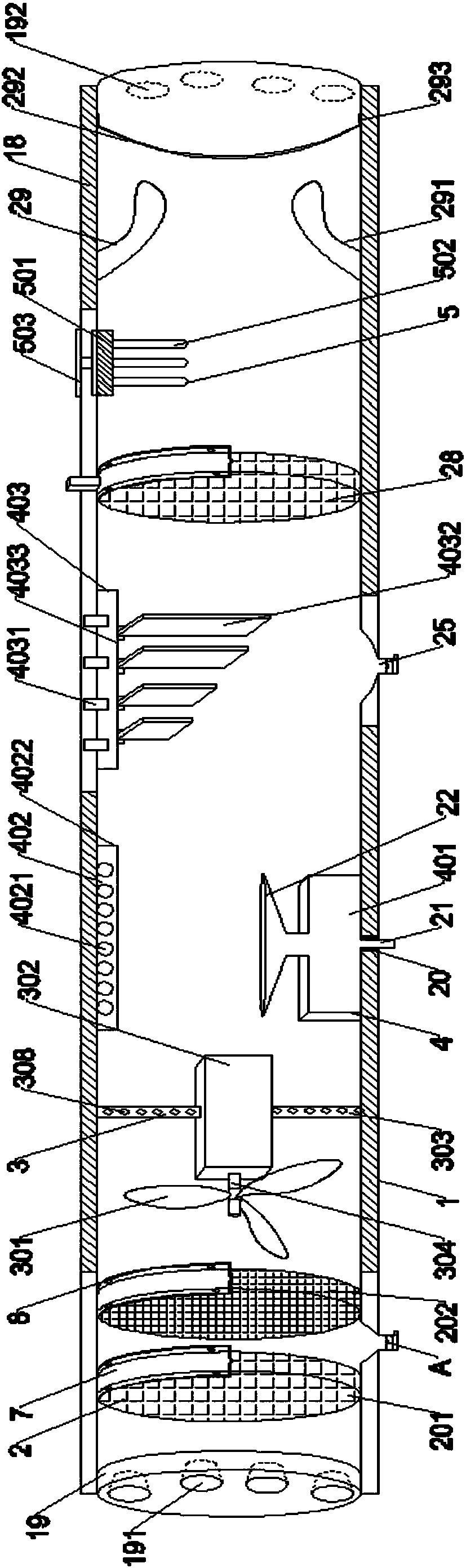

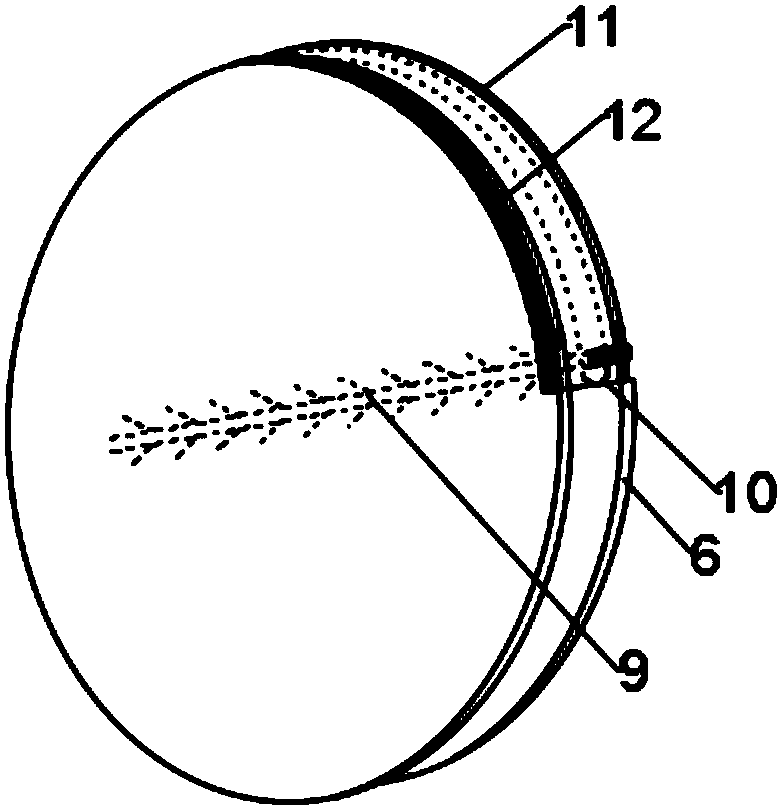

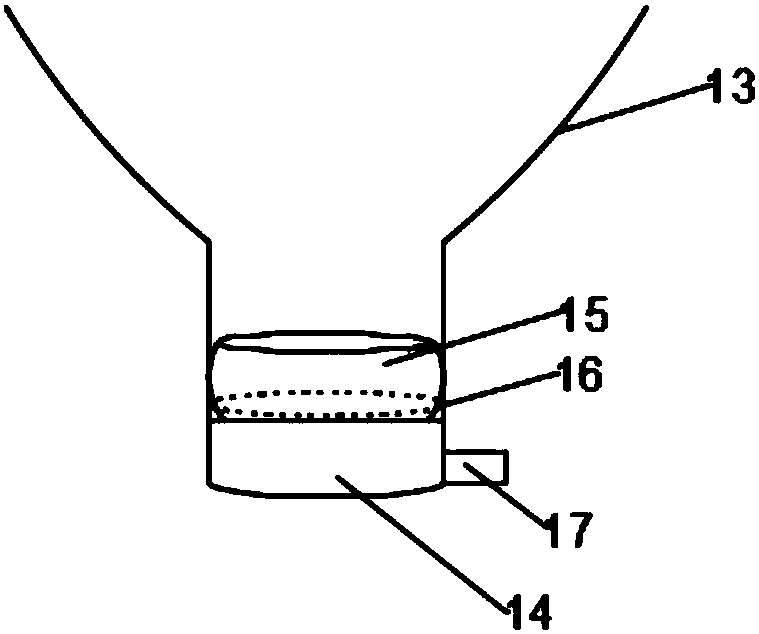

[0036] Such as figure 1 As shown, the present invention provides an air purification device for a flour processing plant, which is based on the principle of ultra-fine mist particle adsorption, including a casing 1 and a filter device 2 and an exhaust device installed in the casing 1 in sequence 3. The fine mist purification device 4 and the sterilization and disinfection device 5, the filter device 2 is to filter large impurities with a large diameter, and the exhaust device 3 is to unidirectionally pump the air to be purified into the casing 1 for purification processing, the fine mist purification device 4 is to generate ultra-fine mist particles to absorb and settle the fine dust in the air, and the sterilization and disinfection device 5 can disinfect the air to ensure the best air quality, thereby ensuring the safety of the flour mill. production efficiency.

[0037] The casing 1 has a double-layer structure, and several sound insulation panels 18 are arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com