Treatment system and treatment process for deeply removing total nitrogen and organic matters in coking-wastewater biochemical yielding water

A technology for treating process and coking wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as low operating cost, difficult to meet discharge standards, poor impact resistance of advanced oxidation, etc. , to achieve the effect of reducing operating costs, ensuring up-to-standard emissions, and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

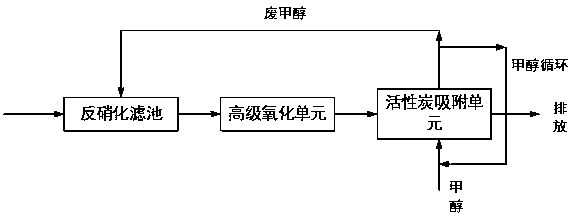

[0029] After biochemical coagulation in a coking plant, the effluent is 203mg / L and the total nitrogen is 36mg / L. It first enters the denitrification filter, and the nitrate nitrogen is converted into nitrogen by denitrification. The total nitrogen content of the denitrification filter effluent is 8mg / L L, the effluent enters the ozone catalytic oxidation unit to remove organic matter, the effluent COD is 106mg / L, which fails to meet the emission standard, the ozone catalytic oxidation effluent enters the activated carbon adsorption unit, and the COD of the effluent is 70-80mg / L. At L, the activated carbon is regenerated, the regeneration method is cycle regeneration, the regeneration time is 60min, the regeneration solid-to-liquid ratio is 30g / L, and the carbon source used for the denitrification filter is collected after the methanol regeneration solution is used for 3 times, and the system finally effluent COD can be reduced to 70-80mg / L, and total nitrogen can be reduced to...

Embodiment 2

[0031] After biochemical coagulation in a coking plant, the effluent is 151mg / L and the total nitrogen is 30mg / L. It first enters the denitrification filter, and the nitrate nitrogen is converted into nitrogen by denitrification. The total nitrogen content of the denitrification filter effluent is 8mg / L L, the effluent enters the Fenton oxidation unit to remove organic matter, the effluent COD is 76mg / L, the ozone catalytic oxidation effluent enters the activated carbon adsorption unit, and the adsorbed effluent COD is 40-50mg / L. When the adsorbed effluent COD exceeds 50mg / L, the activated carbon is Regeneration, the regeneration method is cycle regeneration, the regeneration time is 40min, the regeneration solid-liquid ratio is 50g / L, and the carbon source used for the denitrification filter is collected after the methanol regeneration solution is used 5 times, and the final effluent COD of the system can be reduced to 40- 50mg / L, the total nitrogen is reduced to below 10mg / L....

Embodiment 3

[0033] After biochemical coagulation in a coking plant, the effluent is 246mg / L and the total nitrogen is 41mg / L. It first enters the denitrification filter, and the nitrate nitrogen is converted into nitrogen by denitrification. The total nitrogen content of the denitrification filter effluent is 13mg / L L, the effluent enters the electrochemical unit to remove organic matter, the effluent COD is 121mg / L, the ozone catalytic oxidation effluent enters the activated carbon adsorption unit, and the adsorbed effluent COD is 70-80mg / L. When the adsorbed effluent COD exceeds 80mg / L, the activated carbon is regenerated , the regeneration method is cycle regeneration, the regeneration time is 90min, the regeneration solid-to-liquid ratio is 30g / L, and the methanol regeneration solution is used for 3 times to collect the carbon source for the denitrification filter, and the final effluent COD of the system can be reduced to 70-80mg / L, the total nitrogen is reduced to below 15mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com