Treatment method for extracting gold from high-impurity silver anode slime

A technology of silver anode slime and treatment method, which is applied in the fields of non-ferrous metallurgy and precious metal hydrometallurgy, can solve the problems of unattainable gold purity, complicated treatment process, long treatment time, etc., and achieves high reaction efficiency, reliable process and impurity removal rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

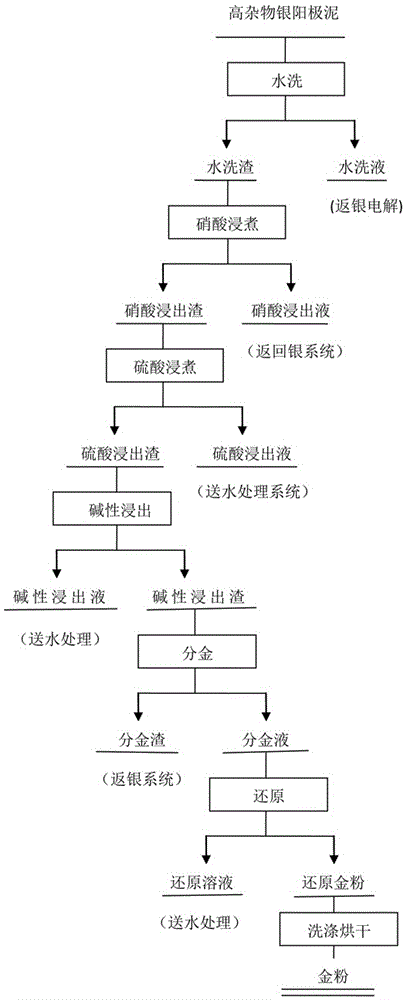

Image

Examples

Embodiment 1

[0025] The treatment method for gold extraction from high-impurity silver anode slime, the specific steps are as follows:

[0026] (1) First wash 3kg of high-impurity silver anode slime produced by silver electrolysis, including Au10.7%, Ag, 5.54%, Cu1.13%, Fe2.01%, Pb1.97%, Sb1.96% , Si2.17%, liquid-solid ratio 3:1, temperature 90°C, stirring time 0.3h, and then filter to obtain washing slag, and the washing liquid is returned to silver electrolysis;

[0027] (2) Add 68% nitric acid to the washing slag obtained in step (1) for leaching, the liquid-solid ratio is 2:1, the temperature is 100°C, the reaction time is 0.2h, and then filtered to obtain the nitric acid leaching slag, and the nitric acid leaching solution is returned to the silver system to recover silver and other valuable metals;

[0028] (3) The nitric acid leaching residue obtained in step (2) was added to 98% concentrated sulfuric acid for leaching, the liquid-solid ratio was 2:1, the temperature was 100°C, the...

Embodiment 2

[0033] The treatment method for gold extraction from high-impurity silver anode slime, the specific steps are as follows:

[0034] (1) First wash 1kg of high-impurity silver anode slime produced by silver electrolysis, including Au11.3%, Ag, 6.12%, Cu1.98%, Fe1.96%, Pb1.55%, Sb2.64% , Si2.02%, liquid-solid ratio 2:1, temperature 95°C, stirring time 0.3h, and then filter to obtain washing slag, and the washing liquid is returned to silver electrolysis;

[0035] (2) Add 65% nitric acid to the washing slag obtained in step (1) for leaching, the liquid-solid ratio is 3:1, the temperature is 98°C, the reaction time is 0.4h, and then filtered to obtain the nitric acid leaching slag, and the nitric acid leaching solution is returned to the silver system to recover silver and other valuable metals;

[0036] (3) Add the nitric acid leaching residue obtained in step (2) to 98% concentrated sulfuric acid for leaching, the liquid-solid ratio is 2:1, the temperature is 100°C, the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com