A kind of method for the cracking of methyl tert-butyl ether to prepare polymer grade isobutylene

A technology of methyl tert-butyl ether and isobutylene, which is applied in the field of methyl tert-butyl ether cracking to produce polymer-grade isobutylene, can solve the problems of difficult control of operating conditions, increased investment and operating costs of water washing towers, etc., and achieves convenient and flexible operation, High utilization rate and high removal rate of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

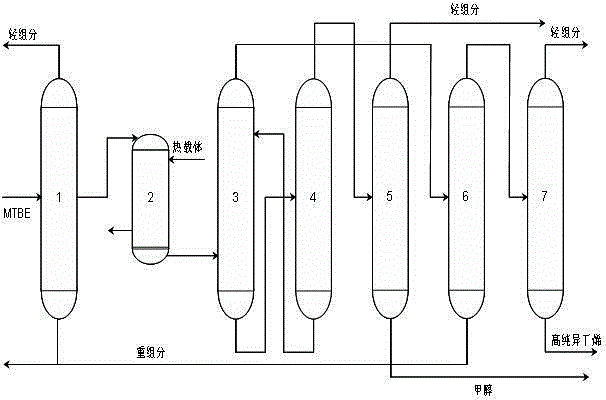

[0025] figure 1 It is a schematic diagram of a typical process for preparing high-purity isobutylene. MTBE is first refined by MTBE refining tower 1, and then enters cracking reactor 2 for cracking reaction under appropriate operating conditions. The cracked product enters water washing tower 3, and the bottoms of water washing tower enter methanol recovery tower 4 and methanol refining tower 5 in turn The methanol is recovered, and the crude isobutylene product from the top of the water washing tower enters the isobutylene heavy-removing tower 6 and the isobutylene light-removing tower 7, and finally the target product is obtained.

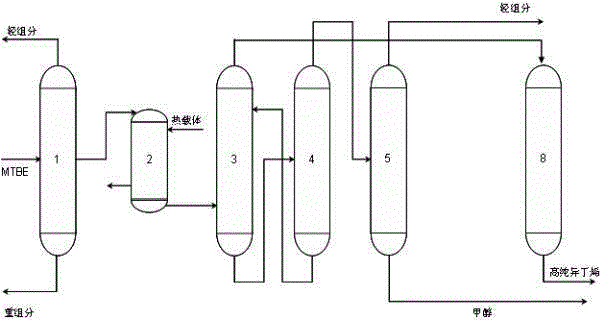

[0026] figure 2 It is a schematic diagram of the process of preparing high-purity isobutylene of the present invention. MTBE is first refined by MTBE refining tower 1, and then enters cracking reactor 2 for cracking reaction under appropriate operating conditions. The cracked product enters water washing tower 3, and the bottoms of water washing t...

Embodiment 1

[0042] Adopt an adsorption tower with a size of Φ100mm (inner) × 1100mm, and sequentially fill with the 13X molecular sieve, amorphous silicon aluminum and 5A molecular sieve adsorbent used in Comparative Example 1, Comparative Example 3 and Comparative Example 5 with a size of 1.5mm from bottom to top. 1 / 3 (by volume). Raise the temperature of the adsorption tower to 80℃, and the volumetric space velocity is 500h -1 The crude isobutylene product stored at a constant temperature of 80°C is measured and passed from top to bottom under 0.1MPa. Sampling and analysis every 4h. The results are shown in Table 4.

Embodiment 2

[0044] Adopt the adsorption tower with a size of Φ100mm (inner)×1100mm, and fill with the 13X molecular sieves of 1.5mm size such as Comparative Example 1, Comparative Example 3 and Comparative Example 5 from bottom to top according to the volume ratio of 10:20:70. Shaped silicon aluminum and 5A molecular sieve. Raise the temperature of the adsorption tower to 80℃, and the volumetric space velocity is 500h -1 The crude isobutylene product stored at a constant temperature of 80°C is measured and passed from top to bottom under 0.1MPa. Sampling and analysis every 4h. The results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com