Compound adsorbing material for heavy metal wastewater treatment and preparation method thereof

A composite adsorption material and wastewater treatment technology, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low adsorption capacity, cumbersome operation, large dosage, etc., and achieve strong Strong adsorption capacity and reduction capacity, strong ability to reduce heavy metals, and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

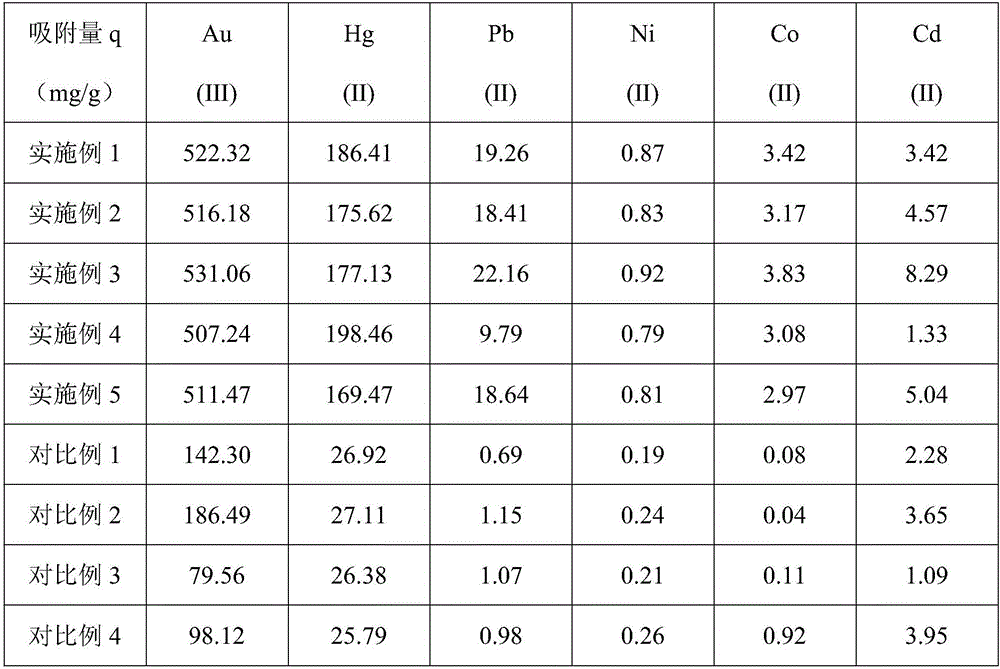

Examples

Embodiment 1

[0021] A composite adsorption material for heavy metal wastewater treatment, which is composed of the following raw materials in parts by weight: 20 parts of kaolin, 15 parts of shell powder, 10 parts of zeolite powder, 20 parts of mesoporous molecular sieves, and 40 parts of ethylenediaminetetraacetic acid metal sodium salt , 70 parts of copper chloride, 30 parts of magnesium chloride.

[0022] The preparation method of the composite adsorption material for the treatment of heavy metal wastewater, the specific steps are as follows:

[0023] (1) take each raw material according to parts by weight;

[0024] (2) Dissolve ethylenediaminetetraacetic acid metal sodium salt in deionized water at a mass ratio of 1:1 to prepare a ethylenediaminetetraacetic acid metal sodium salt solution, and then impregnate mesoporous molecular sieves into ethylenediaminetetraacetic acid sodium metal salt Immerse in the salt solution for 10 hours, so that the ethylenediaminetetraacetic acid metal so...

Embodiment 2

[0030] A composite adsorption material for heavy metal wastewater treatment, which is composed of the following raw materials in parts by weight: 25 parts of kaolin, 20 parts of shell powder, 15 parts of zeolite powder, 30 parts of mesoporous molecular sieves, and 50 parts of ethylenediaminetetraacetic acid metal sodium salt , 75 parts of copper chloride, 40 parts of magnesium chloride.

[0031] The preparation method of the composite adsorption material for the treatment of heavy metal wastewater, the specific steps are as follows:

[0032] (1) take each raw material according to parts by weight;

[0033] (2) Dissolve ethylenediaminetetraacetic acid metal sodium salt in deionized water at a mass ratio of 1.2:1 to prepare a ethylenediaminetetraacetic acid metal sodium salt solution, and then impregnate mesoporous molecular sieves into ethylenediaminetetraacetic acid sodium metal salt Immerse in the salt solution for 12 hours, so that the ethylenediaminetetraacetic acid metal ...

Embodiment 3

[0039] A composite adsorption material for heavy metal wastewater treatment, which is composed of the following raw materials in parts by weight: 30 parts of kaolin, 25 parts of shell powder, 20 parts of zeolite powder, 40 parts of mesoporous molecular sieves, and 60 parts of ethylenediaminetetraacetic acid metal sodium salt , 80 parts of copper chloride, and 50 parts of magnesium chloride.

[0040] The preparation method of the composite adsorption material for the treatment of heavy metal wastewater, the specific steps are as follows:

[0041] (1) take each raw material according to parts by weight;

[0042] (2) Dissolve metal sodium salt of ethylenediaminetetraacetic acid in deionized water at a mass ratio of 1.5:1 to prepare a sodium metal salt solution of ethylenediaminetetraacetic acid, and then impregnate mesoporous molecular sieves into sodium metal ethylenediaminetetraacetic acid Immerse in the salt solution for 14 hours, so that the ethylenediaminetetraacetic acid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com