Advanced treatment method of sewage

A technology of advanced treatment and sewage, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of harsh operating conditions, many procedures, and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

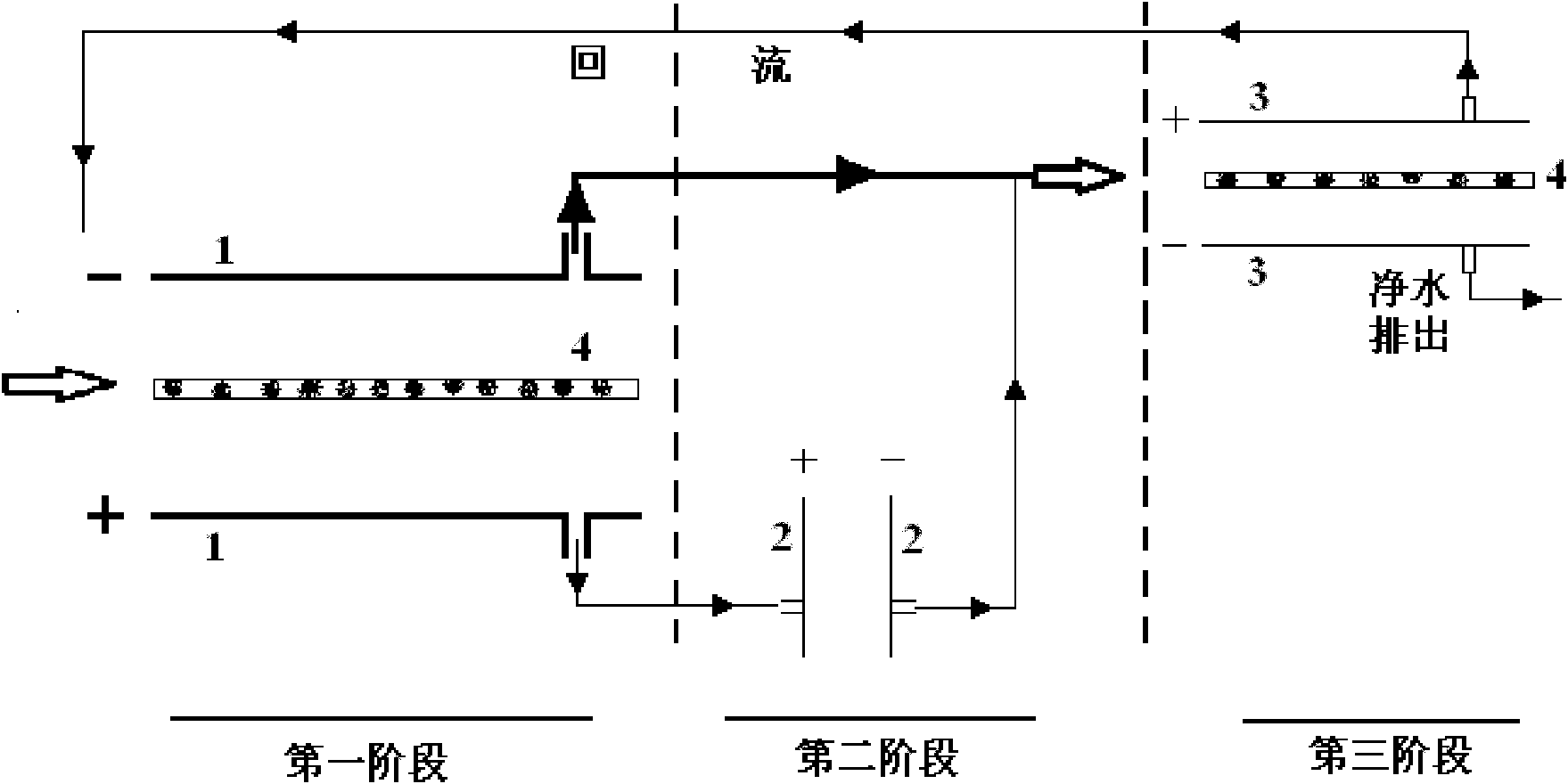

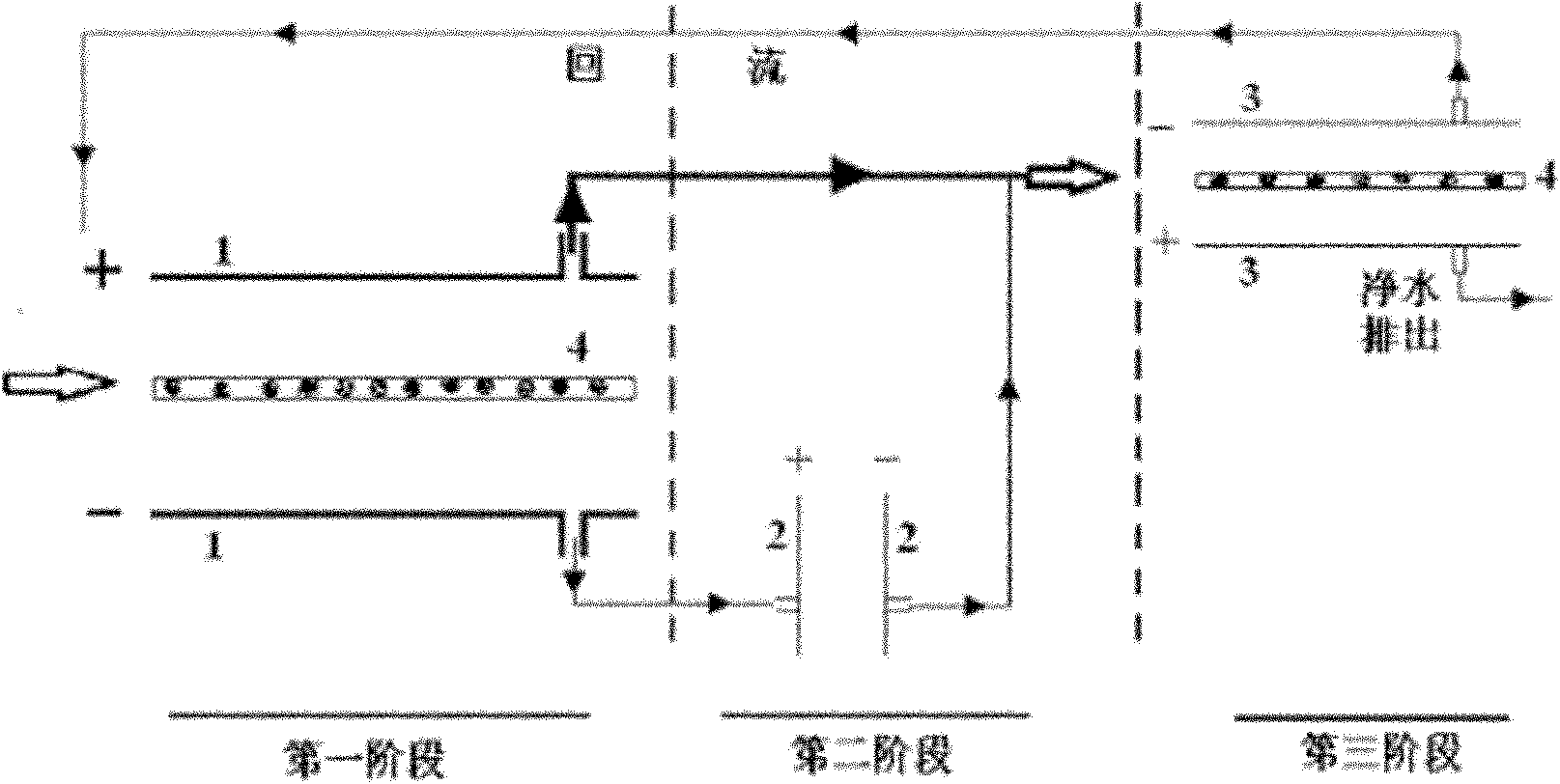

[0093] According to attached figure 1 The process flow of wastewater treatment described in the invention is carried out.

[0094] The first paragraph: In the first group of electrolytic cells 1, the iron plate is used as the anode, and the stainless steel is used as the cathode. The two electrodes are placed in parallel, the distance between the anode and the cathode is 5mm, the middle layer is nylon cloth with a thickness of 0.1mm, and the DC current density is 1A. / m 2 , the influent flow rate is 3L / h, and the residence time is 10 minutes.

[0095] The second paragraph: in the second group of electrolytic cells 2, the iron plate is used as the anode, and the titanium-palladium sold by Baoji Fuxin Nonferrous Metal Products Co., Ltd. under the trade name palladium-plated nickel plate is the cathode, and the distance between the anode and the cathode is 5mm. The DC current density is 10A / m 2 , the influent flow rate is 1L / h, and the residence time is 20 minutes.

[0096] ...

Embodiment 2

[0102] This embodiment does not initiate the second stage of electrochemical degradation process.

[0103] The first paragraph: In the first group of electrolytic cells 1, the iron plate is used as the anode, the graphite is used as the cathode, the two electrodes are placed in parallel, the middle layer is 0.2mm thick cotton cloth, the distance between the anode and the cathode is 5mm, and the DC current density is 1A / m 2 , the influent flow rate is 3L / h, and the residence time is 10 minutes.

[0104] The second stage: In the second group of electrolytic cells 2, the DC current density is 0A / m 2 , that is, the electrochemical degradation process in this section is not activated, and this section is only equivalent to a pipeline.

[0105] The third section: In the third group of electrolytic cells 3, the cathode and anode are both graphite, the middle layer is 0.2mm thick nylon cloth, the distance between the anode and the cathode is 5mm, and the DC current density is 1A / m ...

Embodiment 3

[0110] In this embodiment, the third secondary separation process is not started.

[0111] The first paragraph: In the first group of electrolytic cells 1, the iron plate is used as the anode, and the nickel mesh is used as the cathode. m 2 , the influent flow rate is 3L / h, and the residence time is 10 minutes.

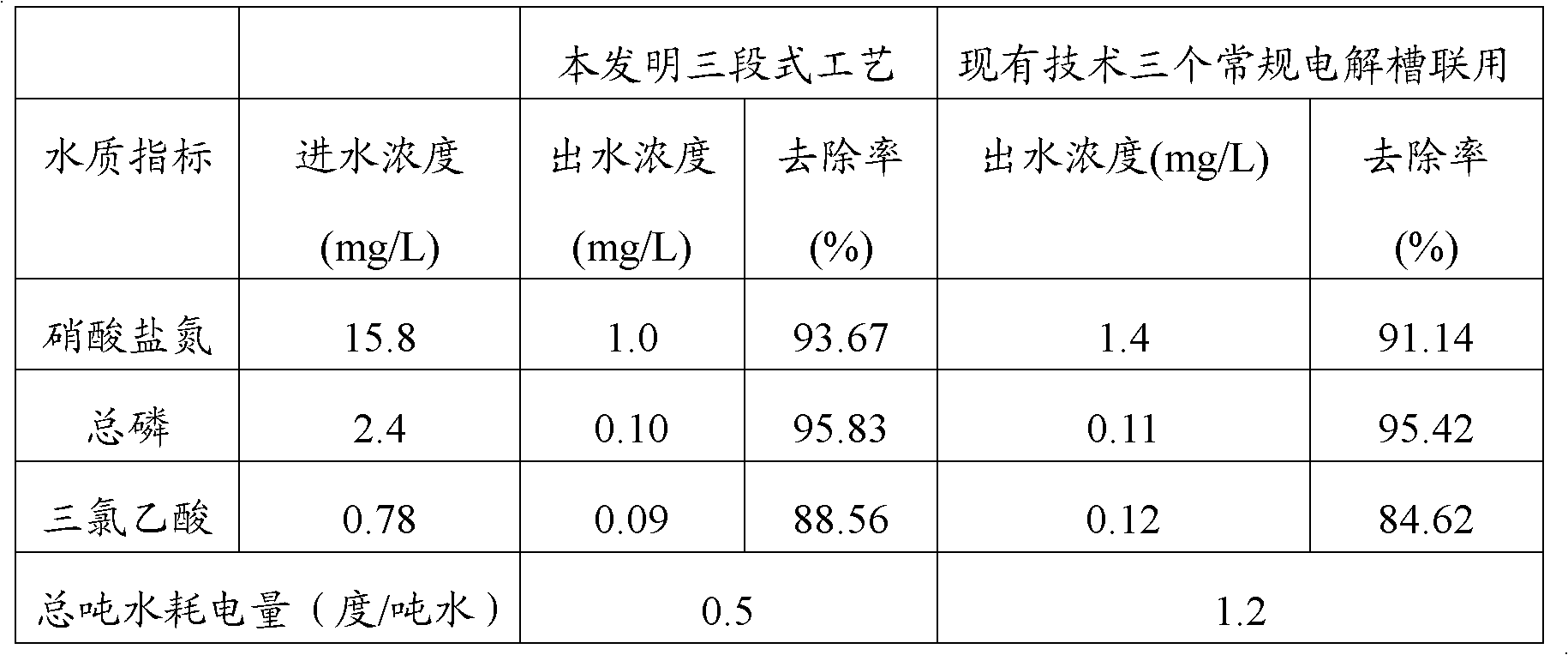

[0112] The second stage: In the second group of electrolytic cells 2, the iron plate is used as the anode, the titanium-palladium is used as the cathode, the distance between the anode and the cathode is 5mm, and the DC current density is 10A / m 2 , the influent flow rate is 1L / h, and the residence time is 20 minutes; the water after treatment in these two stages is collected and combined as the effluent. The influent is the effluent from the secondary settling tank of a certain sewage treatment plant, and the action time of the whole system is 30 minutes. The analysis results of the water quality indicators of the influent and effluent are shown in Table 3.

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com