Method for deeply removing high-concentration nitrate nitrogen in wastewater

A nitrate nitrogen, high-concentration technology, applied in the direction of chemical instruments and methods, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of difficult and thorough removal, lack of technology, poor stability, etc., to achieve economical removal, Efficient removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

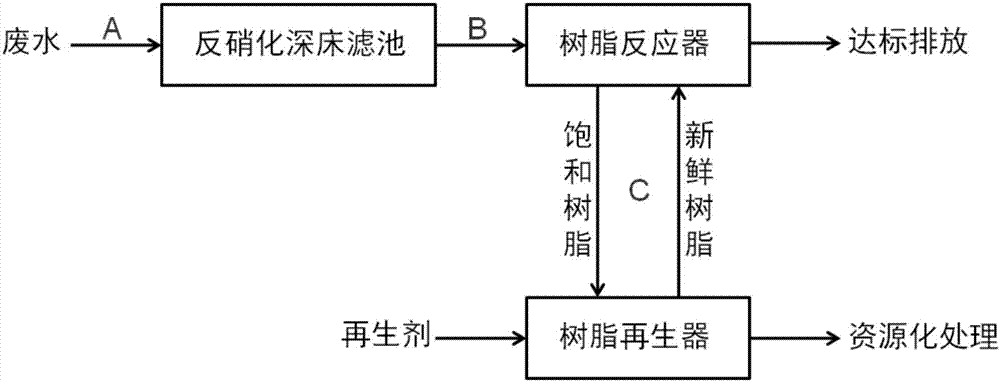

[0028] like figure 1 As shown, the method for the deep removal of high-concentration nitrate nitrogen in wastewater of the present embodiment is carried out in the following steps:

[0029] A. The treatment process of denitrification deep bed filter, that is, NO 3 - -N concentration of 100mg / L, pH of 6.5, temperature of 35℃ to be treated wastewater is pumped into the denitrification deep bed filter, the carbon-nitrogen ratio is adjusted to 3, the hydraulic retention time is 20min, and the concentration of nitrate nitrogen in the effluent is 50mg / L ;

[0030] B. The magnetic ion exchange resin adsorption process is to pump the effluent from the denitrification deep bed filter into the magnetic resin adsorption reactor filled with the Chinese patent application publication number CN 105461846A, and adjust the hydraulic load to 6m 3 / (m 2 h), the adsorption time is 15min, and the concentration of nitrate nitrogen in the effluent is 20mg / L;

[0031] C. The regeneration of the...

Embodiment 2

[0033] The method of deep removal of high concentration nitrate nitrogen in the waste water of the present embodiment is carried out according to the following steps:

[0034] A. The treatment process of denitrification deep bed filter, that is, NO 3 - -N concentration of 80mg / L, pH of 7, temperature of 25°C, the wastewater to be treated is pumped into the denitrification deep bed filter, the carbon-nitrogen ratio is adjusted to 4, the hydraulic retention time is 40min, and the concentration of nitrate nitrogen in the effluent is 40mg / L ;

[0035] B. The magnetic ion exchange resin adsorption process is to pump the effluent from the denitrification deep bed filter into the magnetic resin adsorption reactor filled with the Chinese patent application publication number CN 102430433A, and adjust the hydraulic load to 4m 3 / (m 2 h), the adsorption time is 25min, and the concentration of nitrate nitrogen in the effluent is 15mg / L;

[0036] C. Regeneration of magnetic ion exchan...

Embodiment 3

[0038] The method of deep removal of high concentration nitrate nitrogen in the waste water of the present embodiment is carried out according to the following steps:

[0039] A. The treatment process of denitrification deep bed filter, that is, NO 3 - -N concentration of 60mg / L, pH of 7.5, temperature of 15°C, the wastewater to be treated is pumped into the denitrification deep bed filter, the carbon-nitrogen ratio is adjusted to 6, the hydraulic retention time is 60min, and the concentration of nitrate nitrogen in the effluent is 30mg / L ;

[0040] B. The magnetic ion exchange resin adsorption process is to pump the effluent of the denitrification deep bed filter into the magnetic resin adsorption reactor filled with the Chinese patent application publication number CN 103497281A, and adjust the hydraulic load to 3m 3 / (m 2 h), the adsorption time is 45min, and the concentration of nitrate nitrogen in the effluent is 10mg / L;

[0041] C. The regeneration of the magnetic io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com