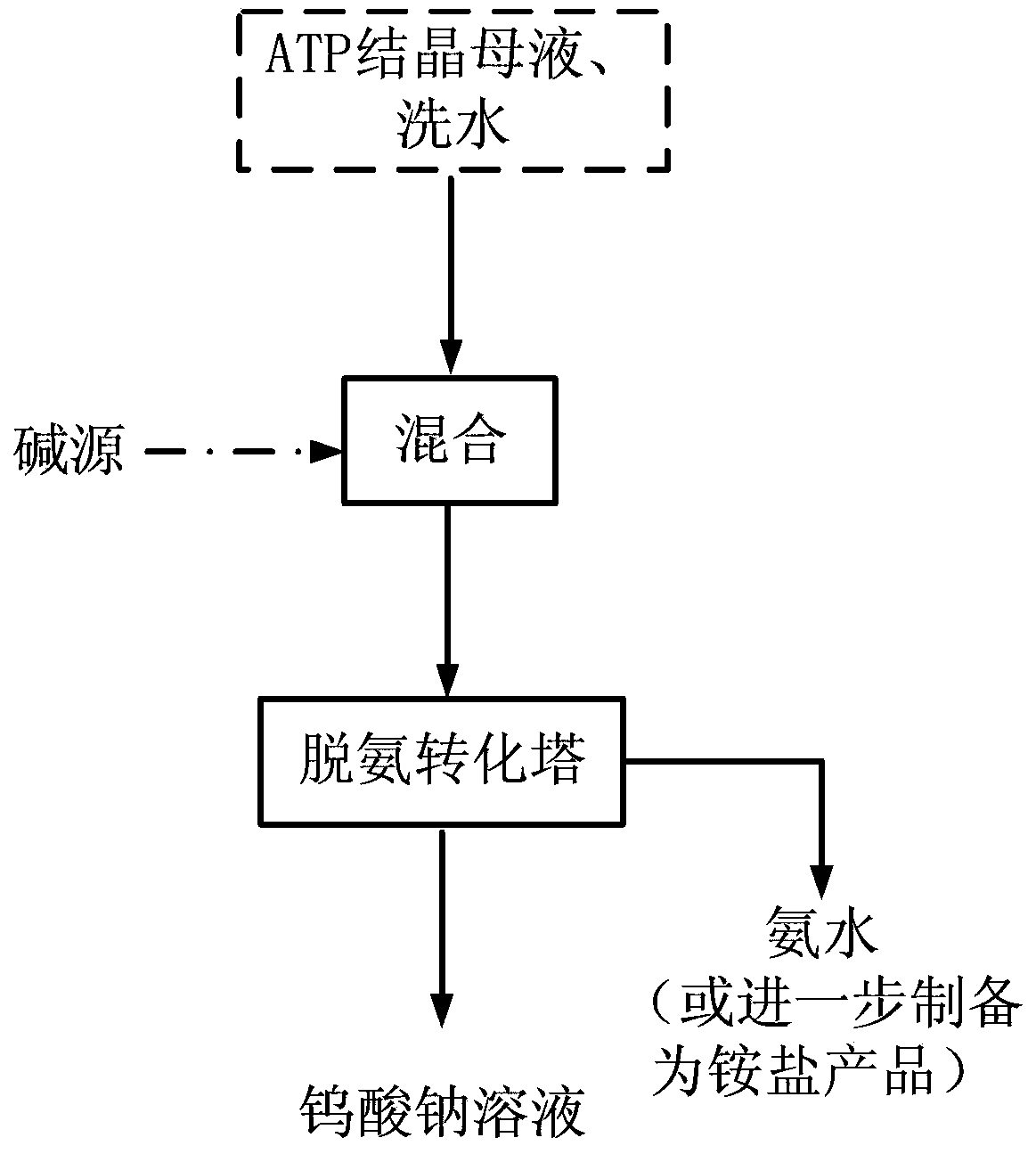

Process of resource comprehensive utilization of tungsten crystal-containing mother solution and washing water

A technology for crystallization mother liquor and resource utilization, which is applied in the field of tungsten smelting, can solve the problems such as metatungstate and heteropolysalt cannot be effectively destroyed, limit stable operation and wide application, and affect ion exchange operations, etc., and reduce ammonia nitrogen pollution. The transfer of materials, the speed of process transformation, and the effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The ammonium tungstate solution is evaporated and crystallized to produce the crystallization mother liquor of ammonium paratungstate and other products and the washing water produced by washing the ammonium paratungstate with pure water; add sodium hydroxide solution and mix in the mixing reaction kettle to control the alkalinity of the mixed solution at 8.0g / L; The mixed liquid is transported to the packed tower with a pump, steam is directly fed into the bottom of the tower, and the operating pressure in the tower is 0.02MPa. After the ammonia in the tungsten-containing crystallization mother liquor is deammonized by the packed tower, the ammonia-containing steam is recovered as ammonia water through condensation; APT It is converted into sodium tungstate in the packed tower, and the conversion time is about 90 minutes. Part of the converted sodium tungstate solution is refluxed through the circulating water pump, and the reflux flow rate is 1.5 times that of the feed ...

Embodiment 2

[0043] The ammonium tungstate solution is evaporated and crystallized to produce the crystallization mother liquor of ammonium paratungstate and other products and the washing water produced by washing the ammonium paratungstate with pure water; in the mixing reaction kettle, add sodium carbonate solution to adjust the pH of the mixed solution to 10, and then add sodium hydroxide solution, Control the alkalinity of the mixed solution at 9.0g / L; use a pump to transport the mixed solution to the plate tower, and a reboiler is installed at the bottom of the tower to heat the liquid to generate steam. After the deamination treatment of the plate tower, the ammonia-containing vapor is absorbed by hydrochloric acid to prepare ammonium chloride product; APT is converted into sodium tungstate in the plate tower, and the conversion time is about 40 minutes. The converted sodium tungstate solution is partially refluxed through the circulating water pump. The return flow is 2.0 times of t...

Embodiment 3

[0045] The ammonium tungstate solution is evaporated and crystallized to produce the crystallization mother liquor of ammonium paratungstate and other products and the washing water produced by washing ammonium paratungstate with pure water; in the mixing reaction kettle, add sodium bicarbonate solution to adjust the pH of the mixed solution to 10, and then add sodium hydroxide solution , control the alkalinity of the mixed solution at 10.0g / L; use a pump to transport the mixed solution to the composite structure tower, a reboiler is installed at the bottom of the tower to heat the liquid to generate steam, the operating pressure in the tower is 1.2MPa, and the tungsten-containing crystallization mother liquor After the ammonia is deaminated by the composite structure tower, the ammonia-containing steam is recovered as ammonia water through condensation; APT is converted into sodium tungstate in the composite structure tower, and the conversion time is about 30 minutes. The conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com