Method for wet impurity removal of industrial silicon

An industrial silicon and wet technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as difficult to achieve deep impurity removal, and achieve the effect of easy operation, simple equipment, and increased contact opportunities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

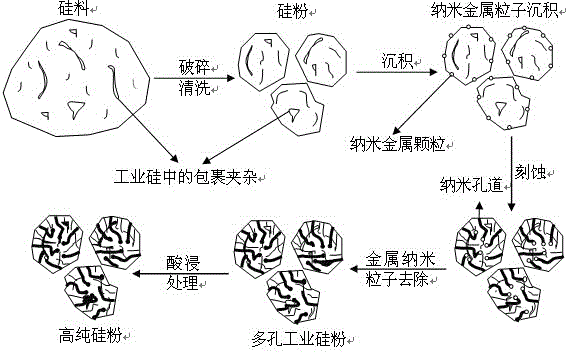

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of silicon material: crush and grind industrial silicon material (purity: 99.8wt%), wash silicon powder (0.5~50μm) with deionized water, soak the silicon powder with HF with a concentration of 1wt% for 120min, Its liquid-solid ratio is 4:1, the soaking temperature is between 80 °C, and then it is washed with deionized water, filtered and separated;

[0025] (2) Introduction of porous structure: With the help of the catalysis of metal nanoparticles, a one-step metal nanoparticle-assisted etching method is used at 10 °C to etch nano-scale pores on the surface and inside of industrial silicon powder; the one-step metal nanoparticles In the auxiliary etching method, the deposition of metal nanoparticles and the etching of silicon powder are carried out simultaneously in the same reaction system, and the selected reaction system is HF / AgNO 3 The reaction system was stirred in a dark room (rotation speed: 180 rpm) for 48 h. In the mixed solution, the concentr...

Embodiment 2

[0029] (1) Pretreatment of silicon material: crush and grind industrial silicon material (purity: 99.8wt%), clean silicon powder (50~150μm) with deionized water, soak the silicon powder with HF with a concentration of 5wt% for 100min, The liquid-solid ratio is 3:1, the soaking temperature is between 10 °C, and then it is washed with deionized water, filtered and separated;

[0030](2) Introduction of porous structure: With the help of the catalysis of metal nanoparticles, a one-step metal nanoparticle-assisted etching method was used at 100 °C to etch nano-scale pores on the surface and inside of industrial silicon powder; the selected reaction system was HF / KAuCl 4 The mixed solution of , the concentration of HF in the mixed solution is 0.1mol / L, KAuCl 4 The concentration is 5mol / L, and the etching time is 20h;

[0031] (3) Removal of metal nanoparticles: The porous industrial silicon powder containing nano metal particles obtained in step (2) is soaked in an ammonia solut...

Embodiment 3

[0034] (1) Pretreatment of silicon material: crush and grind industrial silicon material (purity: 99.8wt%), clean silicon powder (150~250μm) with deionized water, soak the silicon powder with HF with a concentration of 12wt% for 80min, Its liquid-solid ratio is 5:1, the soaking temperature is between 30 °C, and then it is washed with deionized water, filtered and separated;

[0035] (2) Introduction of porous structure: With the help of the catalysis of metal nanoparticles, a one-step metal nanoparticle-assisted etching method was used at 25 °C to etch nano-scale pores on the surface and inside of industrial silicon powder; the selected reaction system was HF / K 2 PtCl 6 solution, the concentration of HF in the mixed solution is 33mol / L, K 2 PtCl 6 The concentration is 10 mol / L, and the etching time is 0.1h;

[0036] (3) Removal of metal nanoparticles: The porous industrial silicon powder containing nano metal particles obtained in step (2) was soaked in a hydrogen peroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com