Deep treatment process for comprehensive wastewater containing heavy metals

A comprehensive wastewater and advanced treatment technology, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problem of gradual decline in resin exchange capacity, difficulty in controlling treatment costs, real-time tracking of pollutant concentration and flow changes Difficulties and other problems, to achieve the effect of saving regeneration agents and column washing water, solving resin pollution and poisoning, and achieving long-term stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

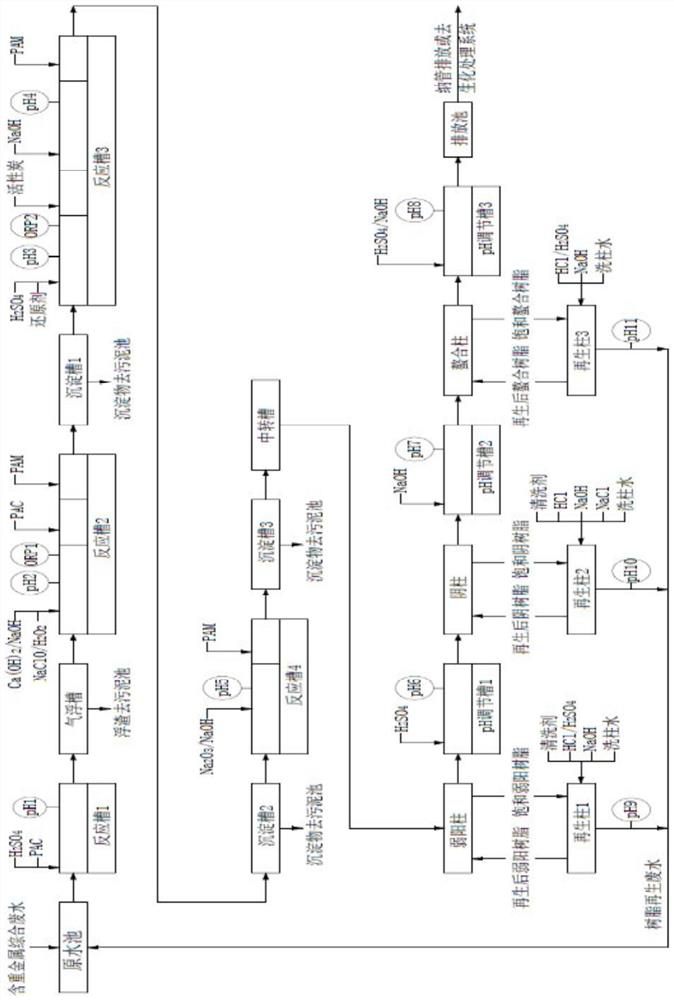

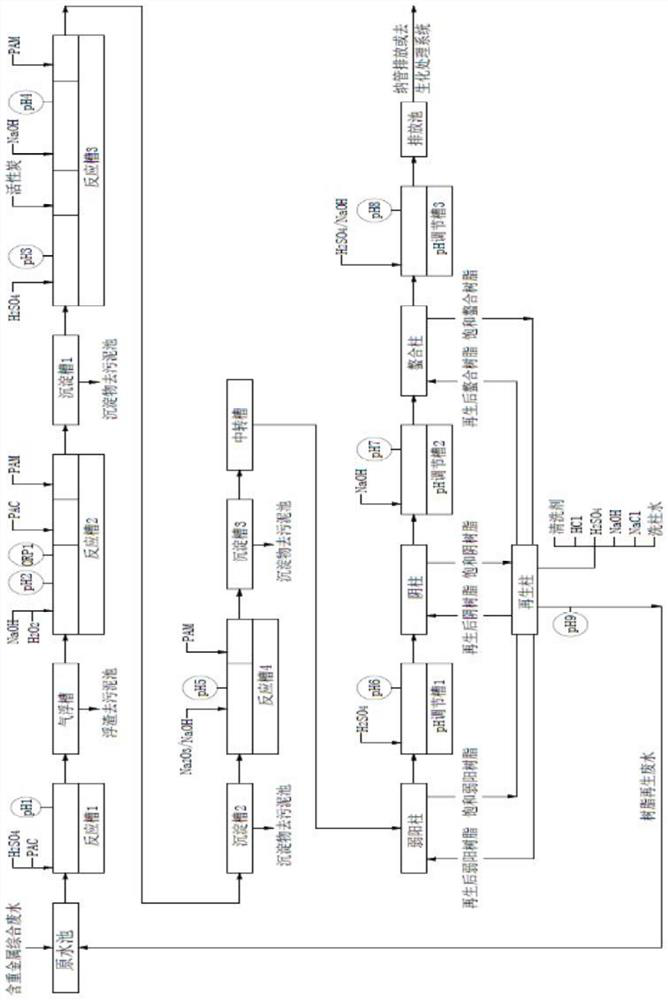

[0071] This embodiment provides a combined ion exchange technology for treating heavy metal-containing comprehensive wastewater system and control process such as figure 2 shown.

[0072] The non-ferrous metallurgical enterprises involved in this embodiment produce 4000m 3 heavy metal-containing comprehensive wastewater. According to 200m 3 / h run.

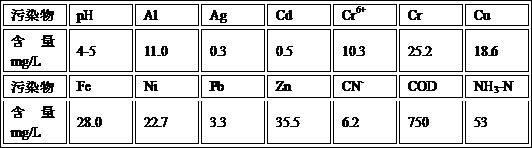

[0073] The composition of wastewater is shown in Table 1

[0074] Table 1

[0075] Pollutants pH Ni Cu co Zn CD Pb As Hg Mg Petro Contentmg / L 6-9 60.57 25.72 20.68 15.03 1.58 8.63 13.06 0.52 86.72 63

[0076] Note 1: pH value is dimensionless;

[0077] Note 2: Petroleum constituents include solvent oil, extractant and organic complex, etc.

[0078] Wastewater treatment requirements: After treatment, the waste water reaches the special discharge limit of heavy metal content in the "Discharge Standard for Copper, Nickel and Cobalt Industrial Pollutants" (GB25467-2010). The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com